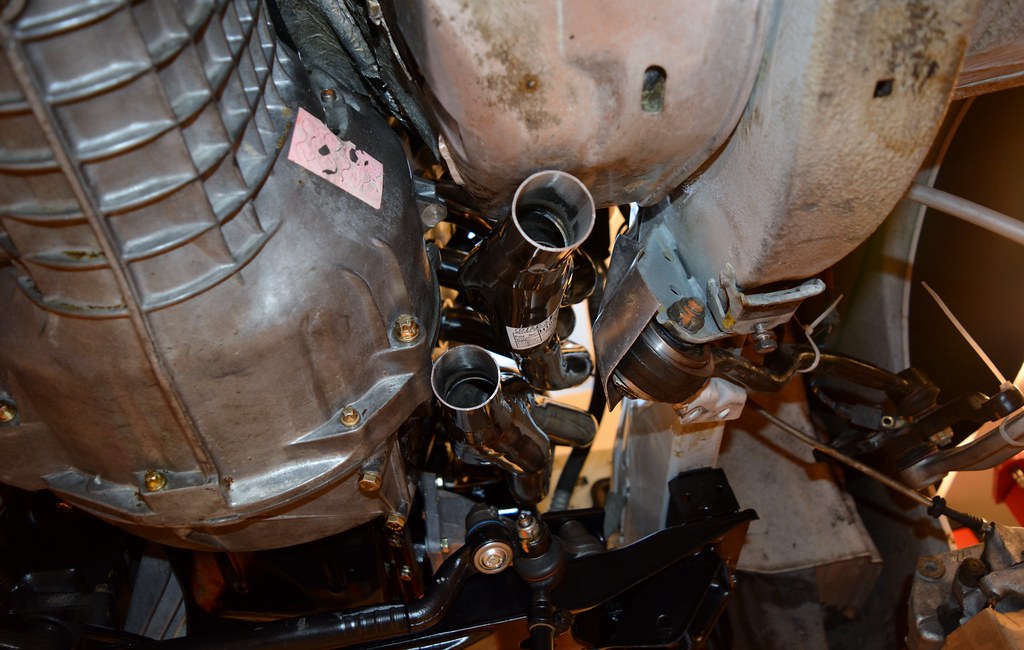

How does a water pump/alternator belt end up like this? Did it get caught by the other belts and sucked through them? This is the first time I've ever had a belt fail in anger on me (lucky, inexperienced, you choose).

Fortunately it happened right near home and I got home before it overheated.

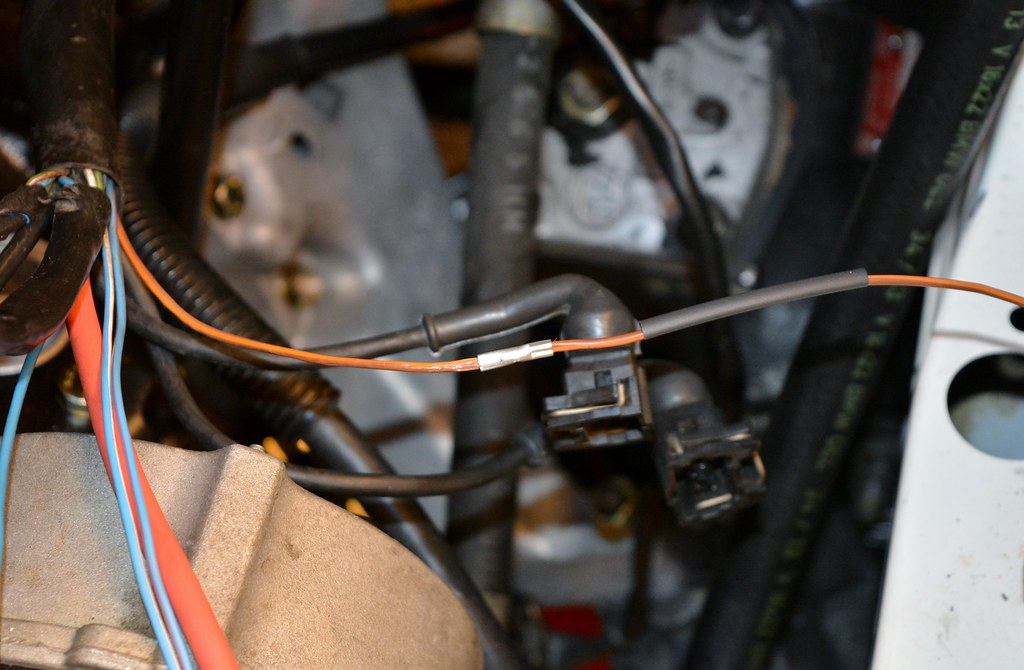

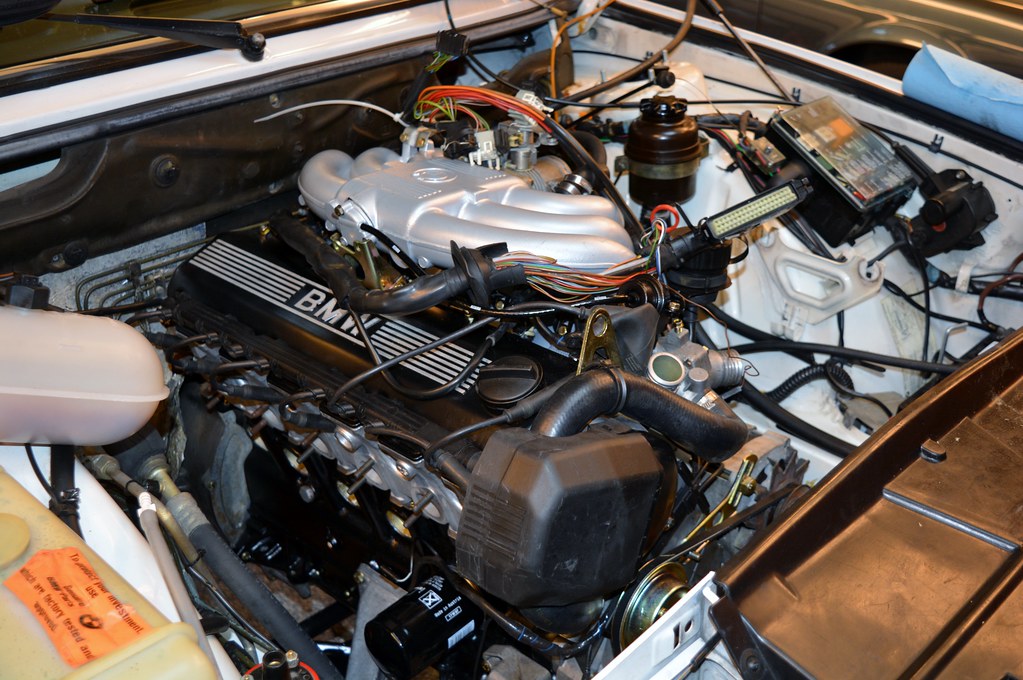

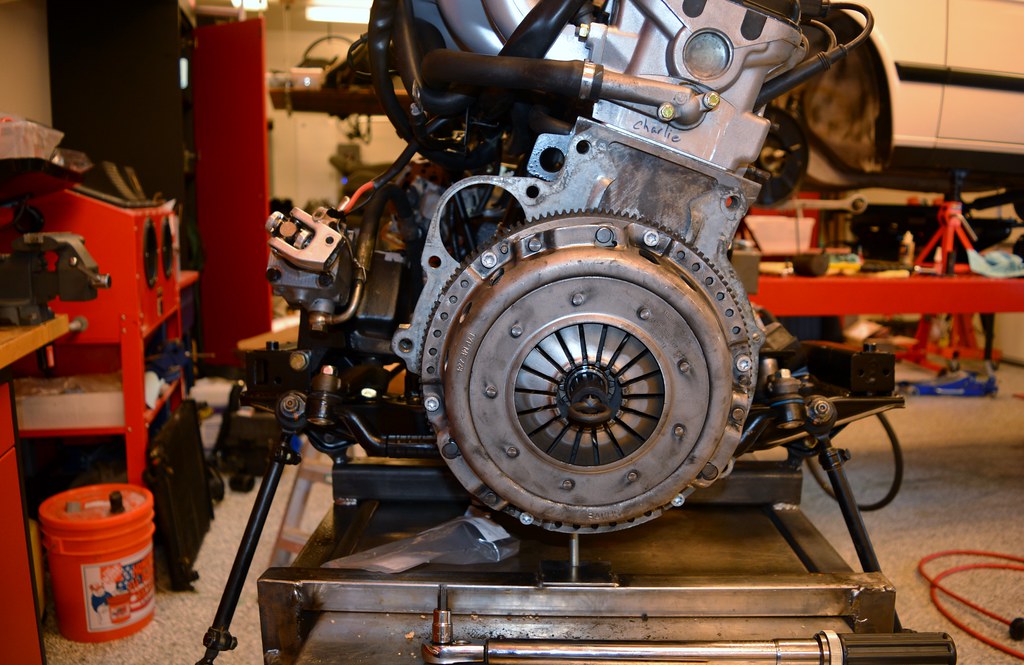

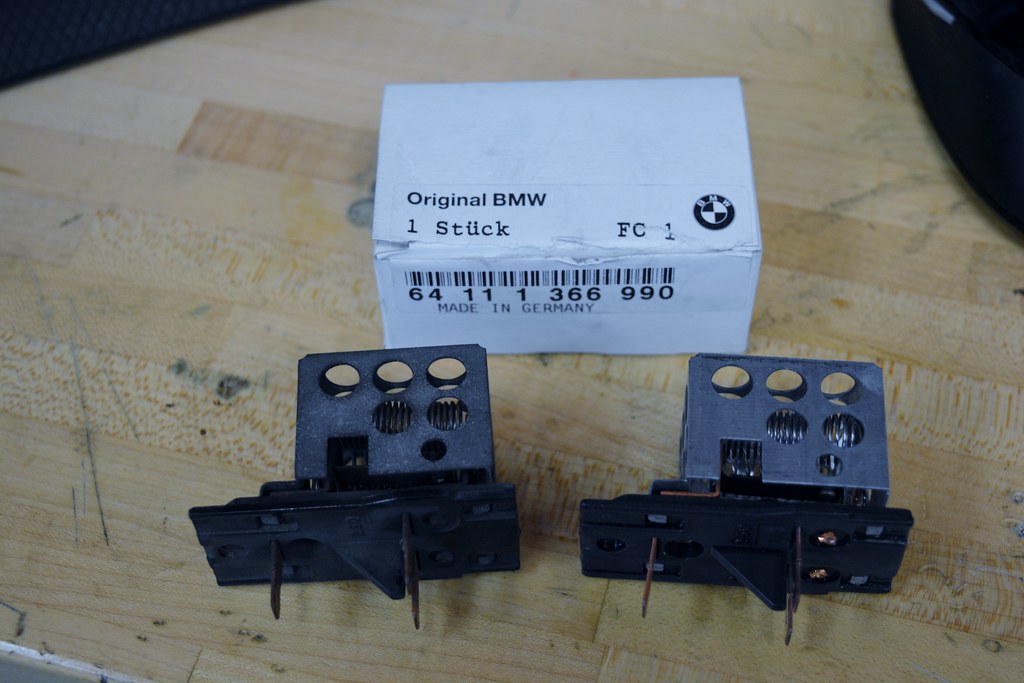

The pully on the alternator looked a little wobbly. It was from a donor motor. I *knew* I should have just sprung for a rebuilt alternator, and stopped when I saw it wasn't straight, but I was trying to be somewhat frugal. That'll teach me.

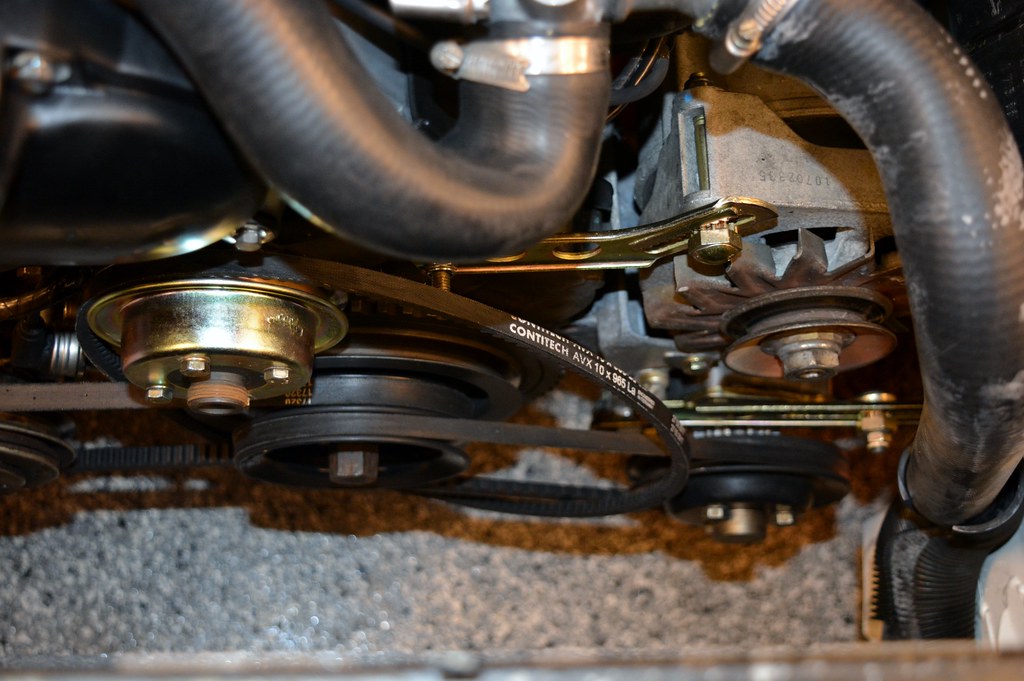

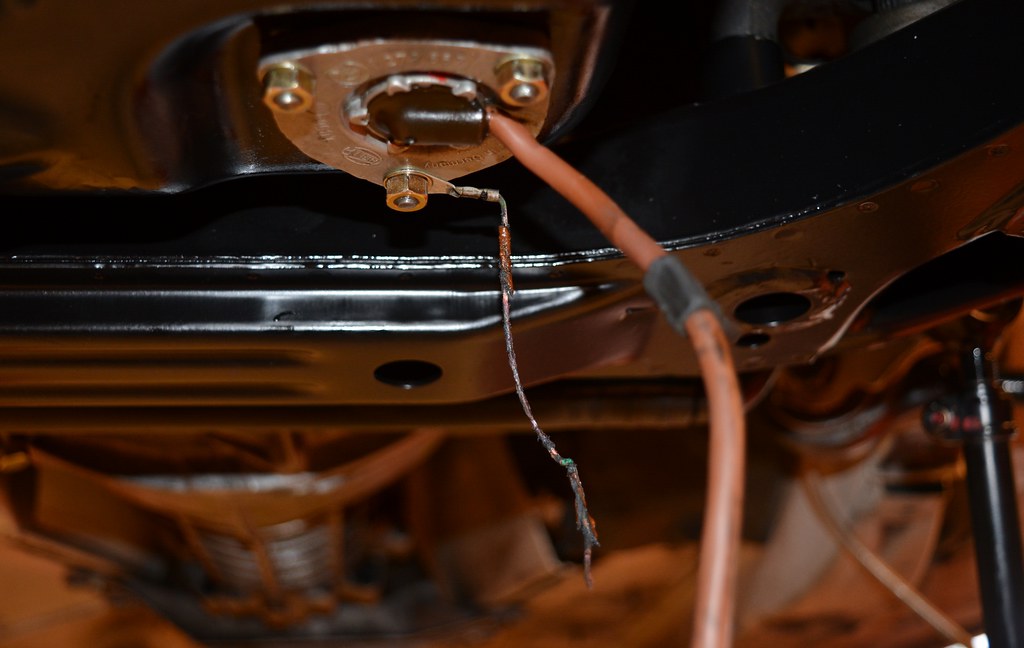

Here's what that Escher belt looks like. You can see how it was damaged winding its way under the other two belts.

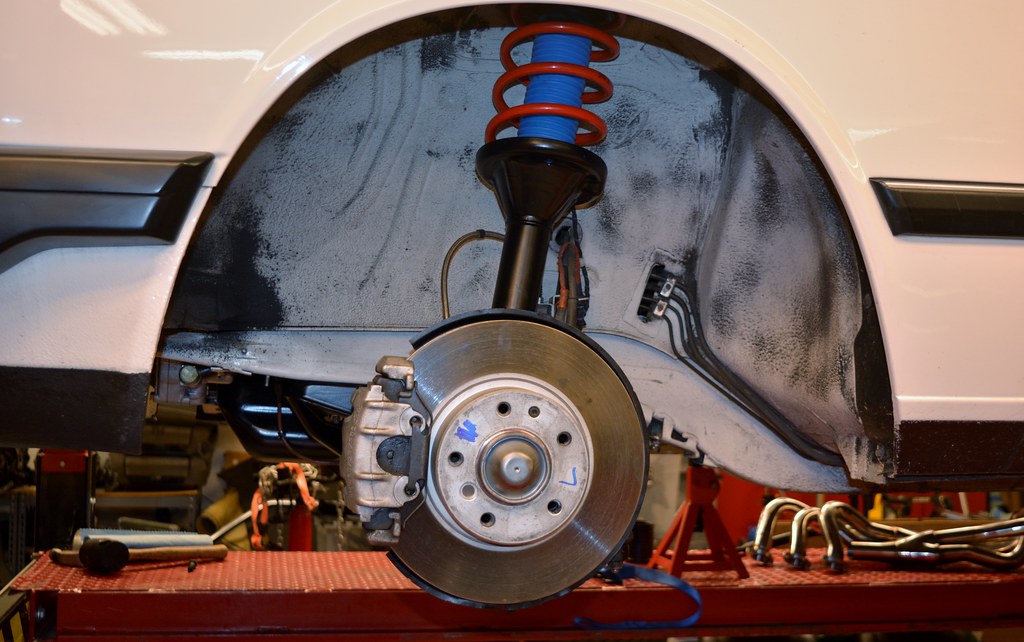

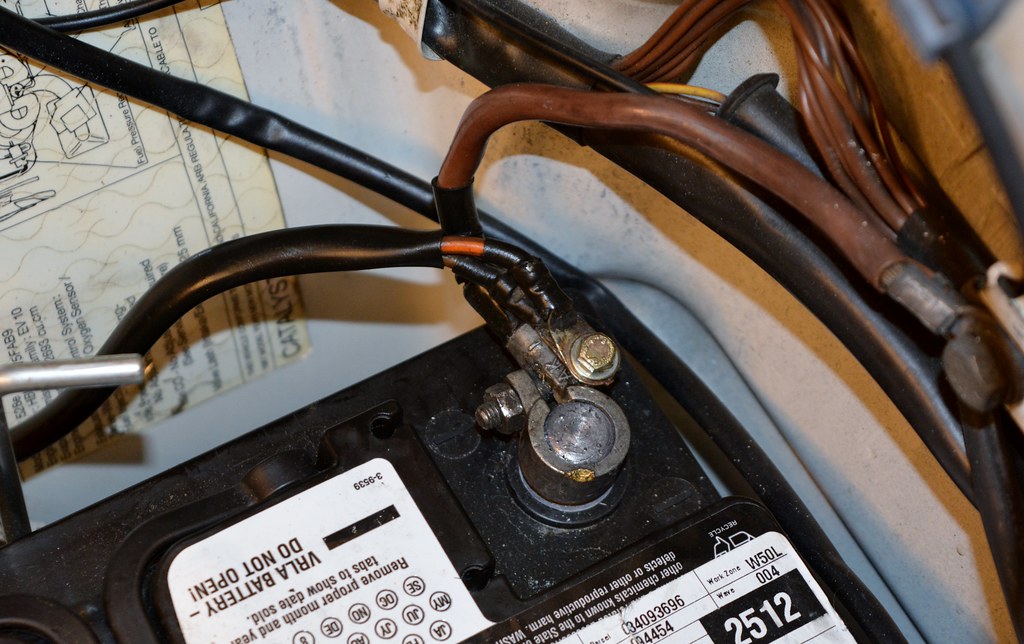

I needed lunch and the Porsche needed some exercise as it's been sitting for a few weeks. So I drove to O'Riellys just to see if they had a reman'd 90A alternator. Sure enough they did. Only $83+core. I have three so giving up a core was no biggie. I pulled a straight pulley off one of the spares and installed the new/refubed unit.

No wobbly and I dare say a bit less belt noise. Went for a spirited test drive (with all tools required to fix the belt if it came off again) and no issues.

Leave a comment: