Originally posted by dvallis

View Post

I have a set of VAC springs (Eibach makes them) and it is hard to push the inner spring thru the outer spring.

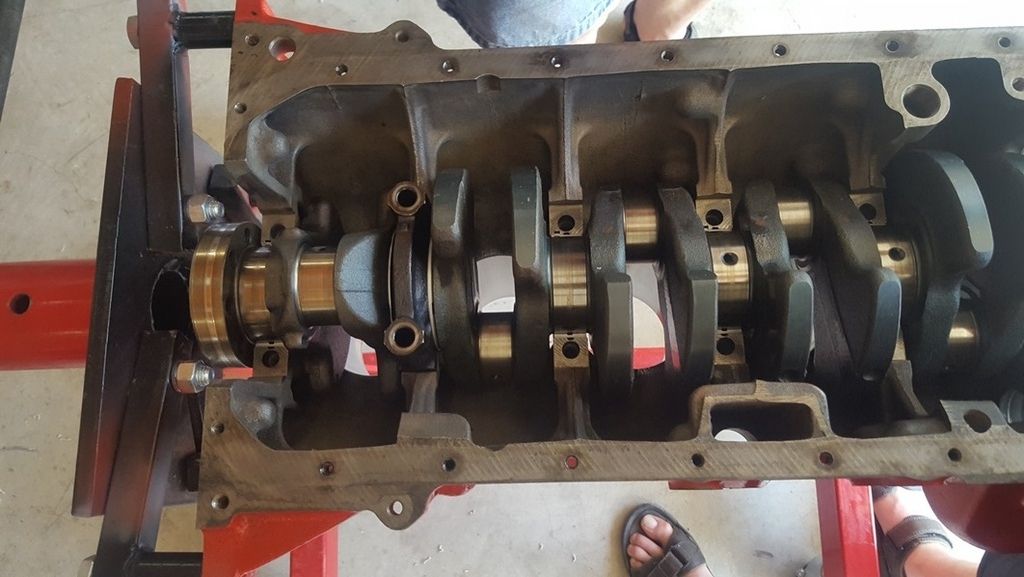

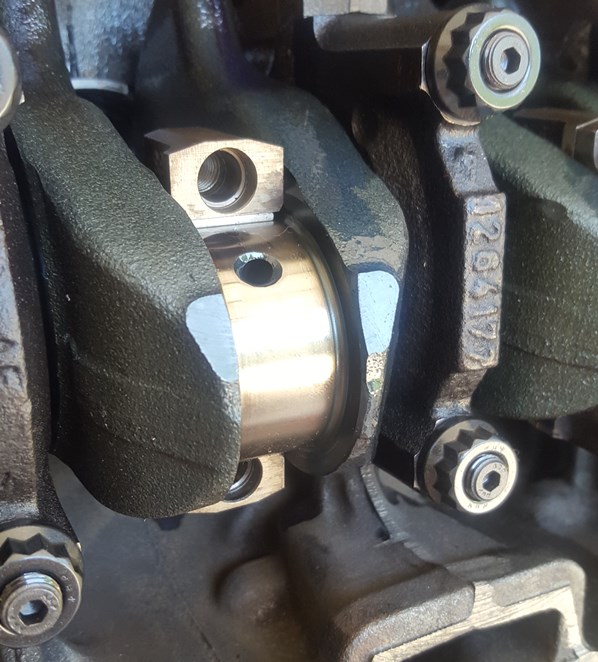

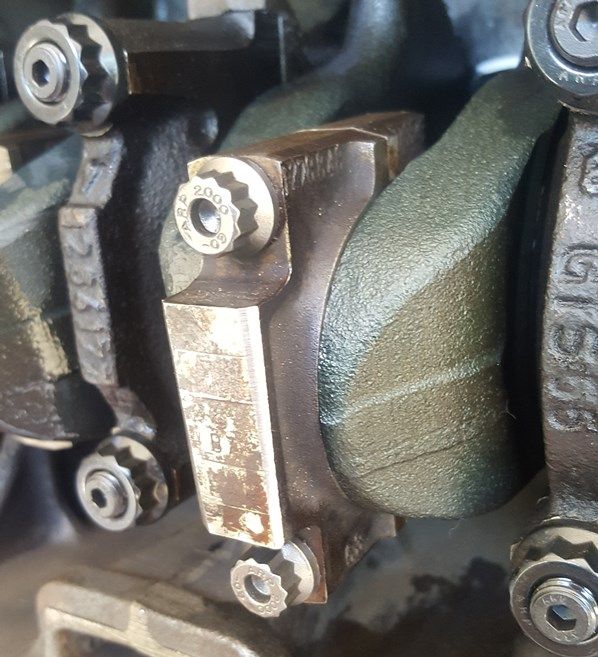

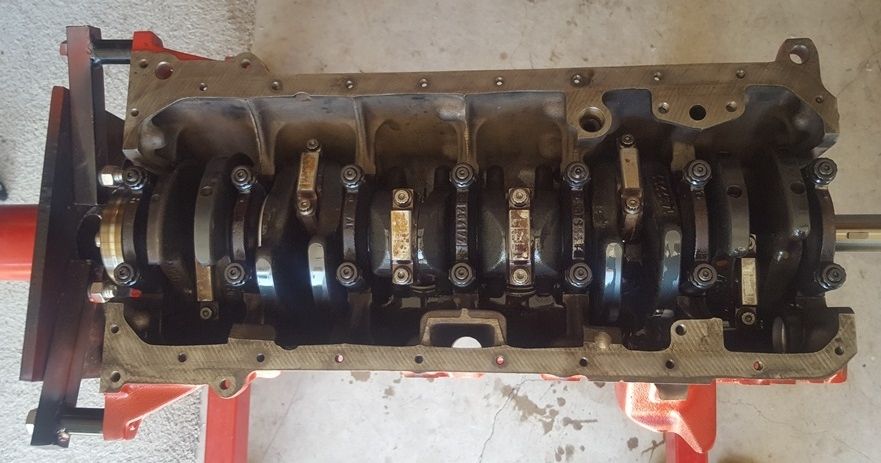

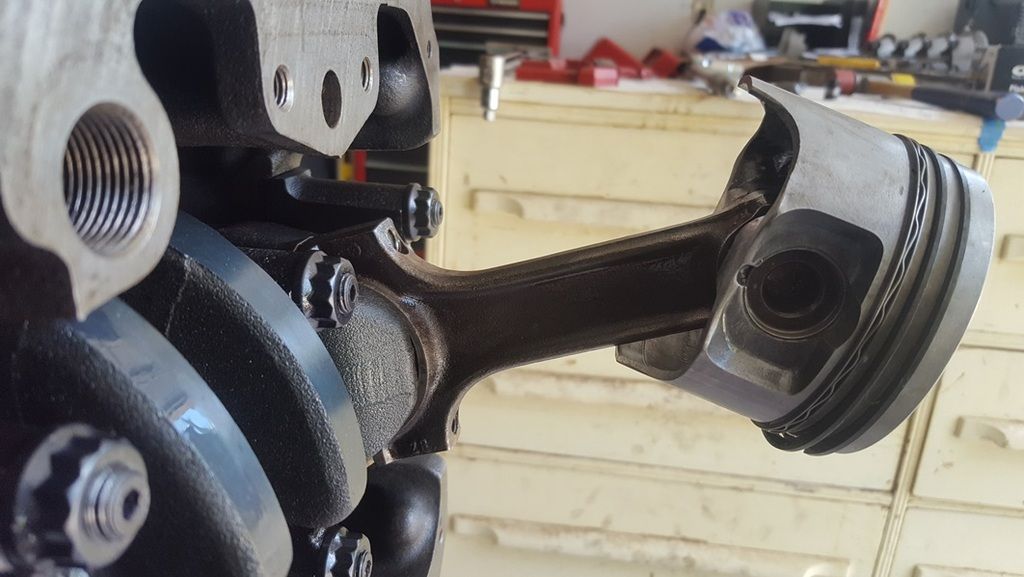

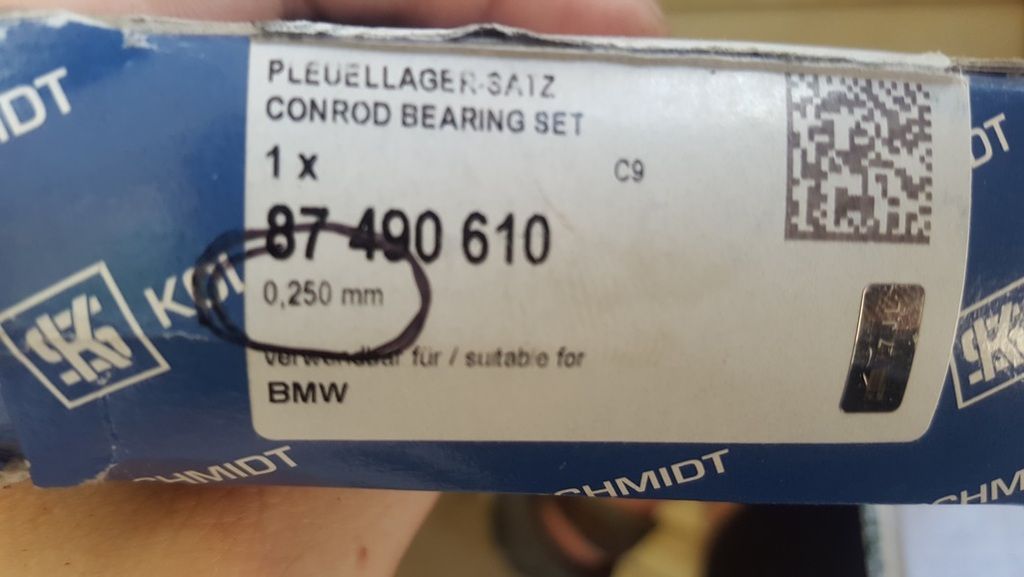

That's about 50 ft-lbs right there. The whole engine had roughly 300 ft-lbs or more rotating friction. FOOOK! Removed the rod bearings and everything rotates smooth as glass. No side to side binding or piston interference.

That's about 50 ft-lbs right there. The whole engine had roughly 300 ft-lbs or more rotating friction. FOOOK! Removed the rod bearings and everything rotates smooth as glass. No side to side binding or piston interference.

Comment