Hey guys,

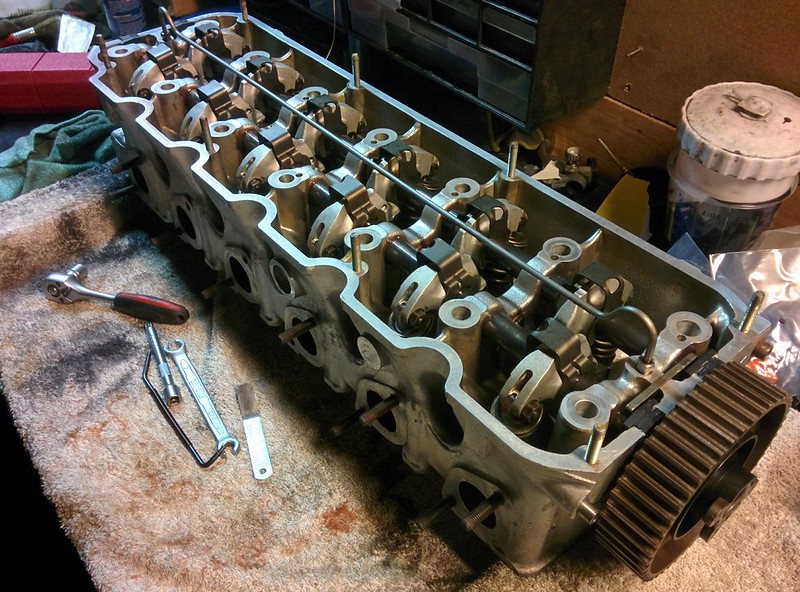

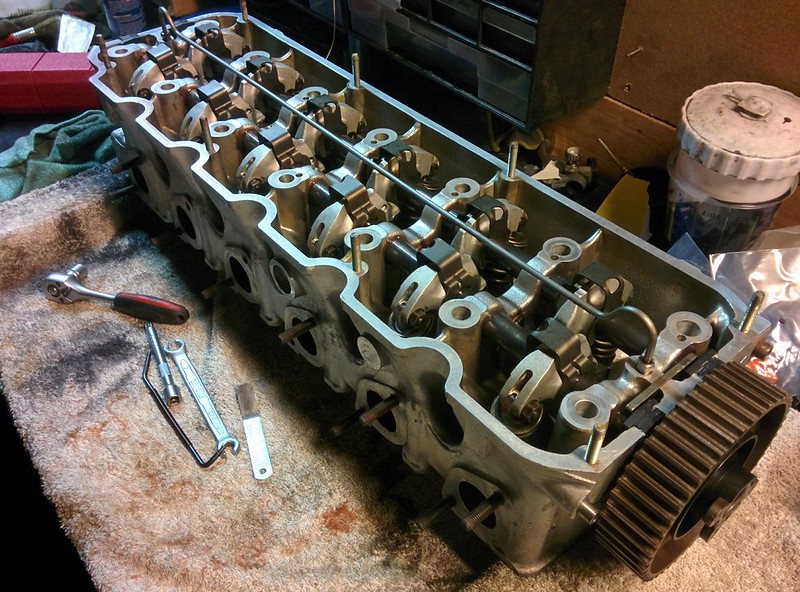

I just assembled my cylinder head but noticed something..

Some info; I got a brand new Kolbenschmidt camshaft, new IE HD rockers, new BMW rocker shafts, new BMW eccentrics, valves and valve seats got a regrind.

Cylinder head got surfaced but still has the little dimples.

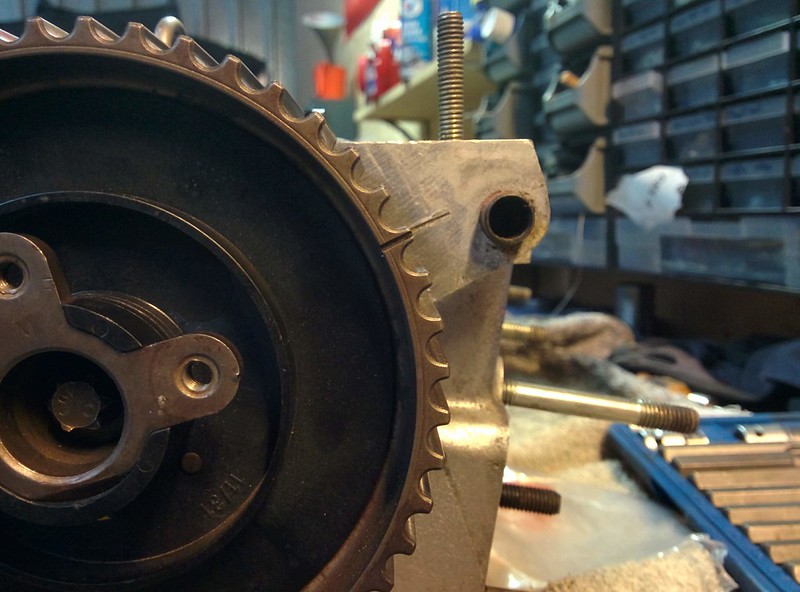

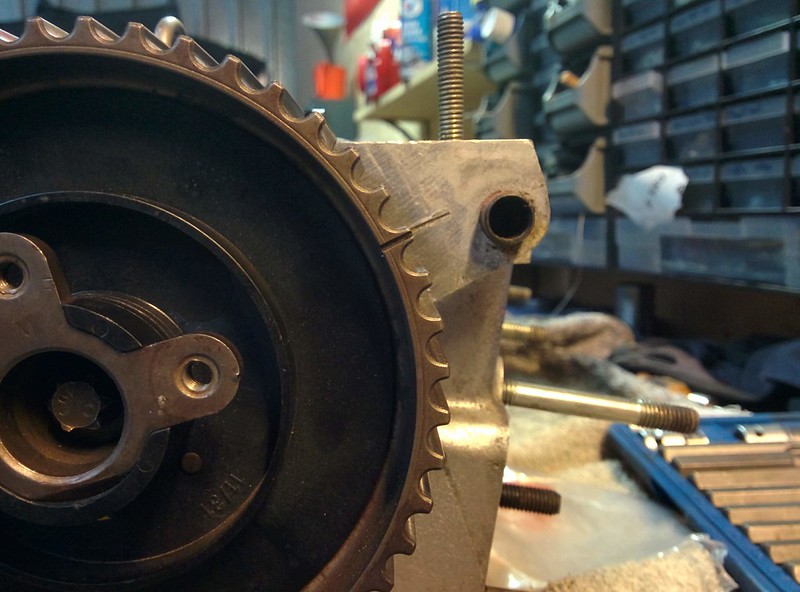

When I set the head at TDC, both valves of cylinder No1 are closed.

However the valves on cylinder No6 are slightly open.

My concern is that both pistons 1 & 6 are on TDC wont the valve of cylinder hit the piston this way?

Is it normal that the valves on cylinder No6 are slightly open?

Exhaust No6

Intake No6

Thanks,

Martijn.

I just assembled my cylinder head but noticed something..

Some info; I got a brand new Kolbenschmidt camshaft, new IE HD rockers, new BMW rocker shafts, new BMW eccentrics, valves and valve seats got a regrind.

Cylinder head got surfaced but still has the little dimples.

When I set the head at TDC, both valves of cylinder No1 are closed.

However the valves on cylinder No6 are slightly open.

My concern is that both pistons 1 & 6 are on TDC wont the valve of cylinder hit the piston this way?

Is it normal that the valves on cylinder No6 are slightly open?

Exhaust No6

Intake No6

Thanks,

Martijn.

Comment