Hi there.

here is my build and i hope i will find some people able to help me out with my issues.

first things first, here is a non exhaustive list of the engine parts.

- M44 block with M44 crank

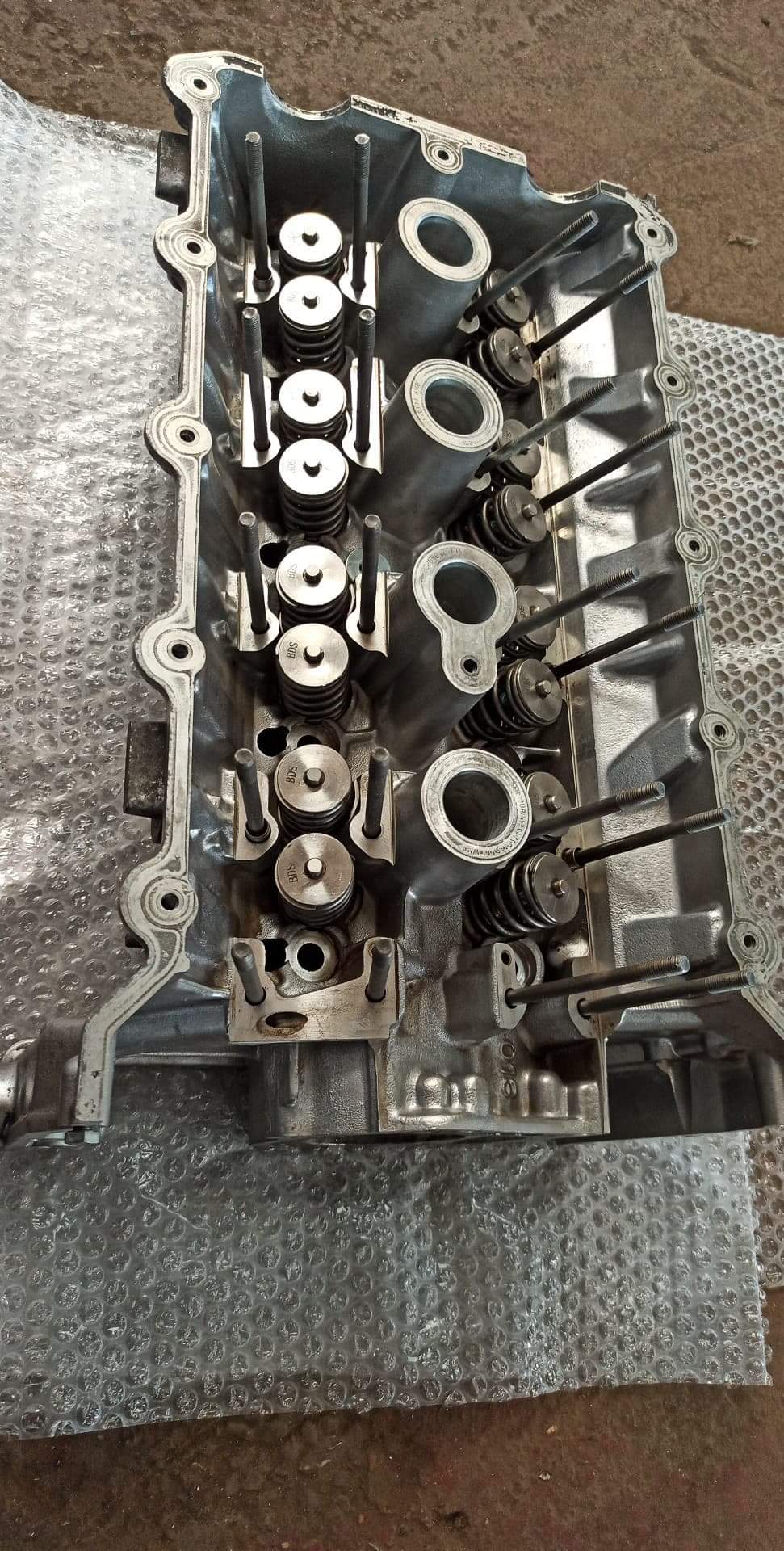

- E36 M42 head, ported, oversize valves and upgraded springs with titanium retainers and solid lifters

-Catcams 272° intake cam with and stock exhaust one (i actually have 290°/272° but afraid i will loose to much driveability at low RPM with this setup)

- Custom intake with 70mm throttle body

- piston wise i currently have standard euro S50B30 pistons , 12.5CR forged S50B30 pistons ordered waiting to be received.

- rods are M44, rebushed to 21mm

- main and rods bearing are ACL

-engine management is a KDATA ECU PNP on the M44 loom.

I did some measurement on the engine but by lack of experience i have a hard time interpreting the results.

crank main journals are all close to 59.98mm (some must be 59.978) so that should be corresponding to the Green bmw standars (between 59.977 and 59.983)

I did a test with plastigauge and found close to 0.10 bearing play (that should be divided by 2 to spread to each side of the journal) so 0.05

I also did measurement (becuse i wasn't sure about the plastigage thing) with what we call a "3 touchs" inner micrometer here in france with the bearings in place, torqued down to spec but without the crank obviously to be able to measure. i found close to 60.07 for 4 of the bearings and 60.09 for the one with the trust bearing.

(did the same with an old bearing and found 60.025)

so i get pretty close to the 0.1mm play, so oil film will be between 0.045 and 0.05mm. what do you guys think? BMW technical data say "radial cranshaft bearing play between 0.020 and 0.046"

regarding rods i only checked one the same way and found 0.05mm bearing play (so 0.025mm on each side of the rod journal)

also i have an issue with my compression ratio. i did volume measurement and found around 33cc for head combustion chamber and 24cc for piston and head gasket (1.8mm) volume.

S50B30 pistons have 1.2mm higer compression height than M44 (31.6 for s50 30.4 for M44) I shaved 0.7mm and rod have an offset of 0.5mm to have the same overdeck as standard.... yeah that sound weird and it's my mistake, I listened to a guy for this and i shouldn't have i think.

so that give me a 57cc combustion volume, and with the 485cc given by 83.5mm stroke and 86 bore it result in a CR of 9.5... aiming between 12 and 12.5 to compensated the higher duration cams that will close the intake valve later (12 static CR will give me around 10.4 / 10.5 dynamic CR)

SO yeah, piston volume is way too big, that why i ordered 12.5CR forged S50B30 pistons that comes with a small volume hoping that i will be able to make everything work and have a decent RV.

thats all for now. will post pictures and more stuff tomorow.

here is my build and i hope i will find some people able to help me out with my issues.

first things first, here is a non exhaustive list of the engine parts.

- M44 block with M44 crank

- E36 M42 head, ported, oversize valves and upgraded springs with titanium retainers and solid lifters

-Catcams 272° intake cam with and stock exhaust one (i actually have 290°/272° but afraid i will loose to much driveability at low RPM with this setup)

- Custom intake with 70mm throttle body

- piston wise i currently have standard euro S50B30 pistons , 12.5CR forged S50B30 pistons ordered waiting to be received.

- rods are M44, rebushed to 21mm

- main and rods bearing are ACL

-engine management is a KDATA ECU PNP on the M44 loom.

I did some measurement on the engine but by lack of experience i have a hard time interpreting the results.

crank main journals are all close to 59.98mm (some must be 59.978) so that should be corresponding to the Green bmw standars (between 59.977 and 59.983)

I did a test with plastigauge and found close to 0.10 bearing play (that should be divided by 2 to spread to each side of the journal) so 0.05

I also did measurement (becuse i wasn't sure about the plastigage thing) with what we call a "3 touchs" inner micrometer here in france with the bearings in place, torqued down to spec but without the crank obviously to be able to measure. i found close to 60.07 for 4 of the bearings and 60.09 for the one with the trust bearing.

(did the same with an old bearing and found 60.025)

so i get pretty close to the 0.1mm play, so oil film will be between 0.045 and 0.05mm. what do you guys think? BMW technical data say "radial cranshaft bearing play between 0.020 and 0.046"

regarding rods i only checked one the same way and found 0.05mm bearing play (so 0.025mm on each side of the rod journal)

also i have an issue with my compression ratio. i did volume measurement and found around 33cc for head combustion chamber and 24cc for piston and head gasket (1.8mm) volume.

S50B30 pistons have 1.2mm higer compression height than M44 (31.6 for s50 30.4 for M44) I shaved 0.7mm and rod have an offset of 0.5mm to have the same overdeck as standard.... yeah that sound weird and it's my mistake, I listened to a guy for this and i shouldn't have i think.

so that give me a 57cc combustion volume, and with the 485cc given by 83.5mm stroke and 86 bore it result in a CR of 9.5... aiming between 12 and 12.5 to compensated the higher duration cams that will close the intake valve later (12 static CR will give me around 10.4 / 10.5 dynamic CR)

SO yeah, piston volume is way too big, that why i ordered 12.5CR forged S50B30 pistons that comes with a small volume hoping that i will be able to make everything work and have a decent RV.

thats all for now. will post pictures and more stuff tomorow.

what's weird is that the engine builder that did the head told me that 0.1mm diametral clearance is a little low for an engine that should rev close to 8Krpm. i don't have enough experience to talk about that hence my question here.

what's weird is that the engine builder that did the head told me that 0.1mm diametral clearance is a little low for an engine that should rev close to 8Krpm. i don't have enough experience to talk about that hence my question here.

Comment