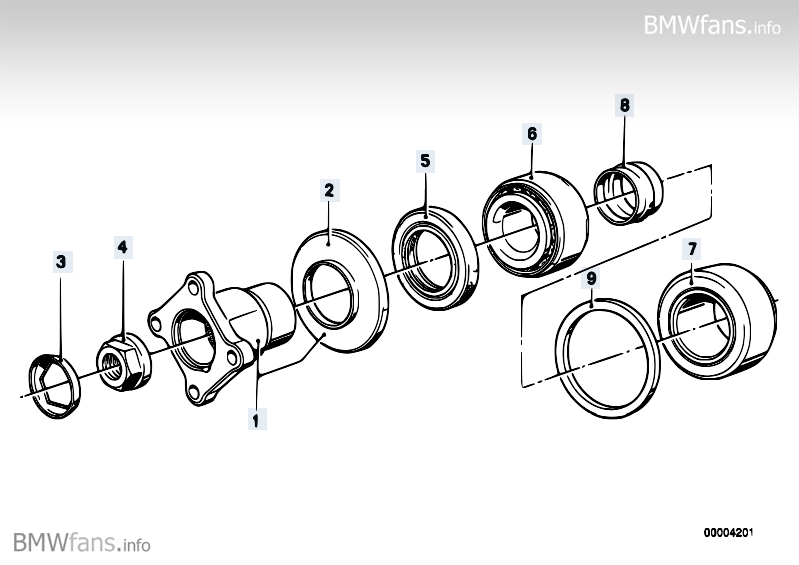

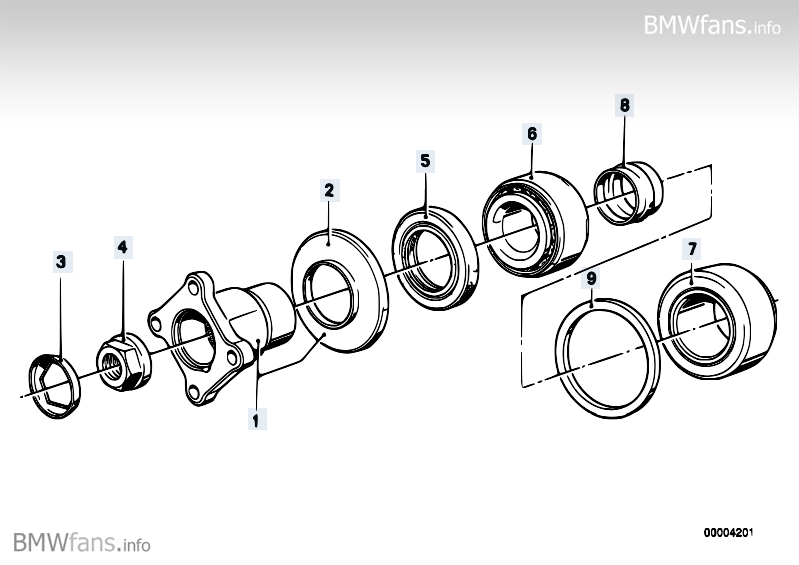

as the title says, maybe someone could please tell me how to properly install primary differential shaft (188 case)? what is the Nm tightening torque for it?

also, heard that its different If you use old or new that bearing sleeve ( 8 )

currently I'm rebuilding my lsd diff, changing clutch discs, bearings etc.

so the bearings will be new, but unfortunately I can't get new that sleeve now, so have to use old one :/

also, heard that its different If you use old or new that bearing sleeve ( 8 )

currently I'm rebuilding my lsd diff, changing clutch discs, bearings etc.

so the bearings will be new, but unfortunately I can't get new that sleeve now, so have to use old one :/

Comment