Wow. I will probably justify buying that soon.

Wilwood pedal set w/ stk rear brake regulator ?

Collapse

X

-

SILBER COMBAT UNIT DELTA (M-Technic Marshal)

RTFM:http://www.r3vlimited.com/board/showthread.php?t=56950Comment

-

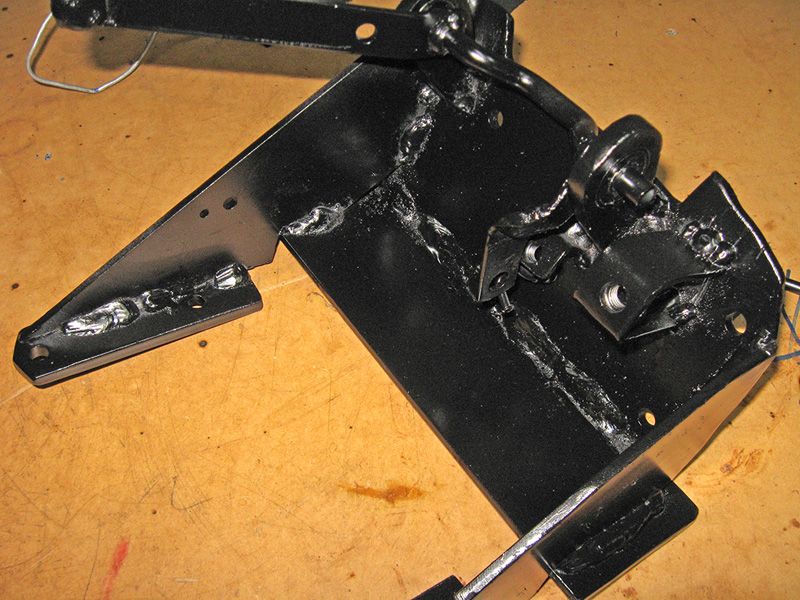

Sure. It's a fucking bastard of a position to make one up and im not 100% sure if the dash will fit yet (without carving out a little foam to clear the lines). Ive made like 7 revisions along the way to fix little problems as Ive come across them, but it's a pretty basic design. I've had to make some concessions along the way as I was determined to run a 6.2:1 pedal ratio, if you run a lesser 5:1 you'll have much more space to locate things. Because of the longer pedals I had to basically mount the pedals as high as I could in order to keep plenty of space between the bottom of the pedals and the floorpan, while keeping an eye on reservoir heights for the remote reservoirs on the other side of the firewall. I had to take everything back out again this week because I had to change the routing of one of the brake lines and I found a slight weep due to a shit quality brake nut, but I've pretty much got all the bugs ironed out now. When It comes time to paint the car im going to pull the pedal box back out and remake it in thinner plate. I went way overboard on thickness, partially because the engineer was being pretty strict being manual brakes and the leverage associated with it, but also because I had plenty of plate steel around. Realistically only needs to be 3mm plate and it'll be pretty solid.

It uses all the factory mounts on the firewall, basically just started off with a flat plate to replicate the factory pedal mount. Then I used the 2 factory mounts on the underside of the dash (near the column) to mount the tilton pedal box through the top mounts of the pedals and locate them where I wanted (basically just bent the plate to change the angle). Once it was where I wanted it, I just braced between the plate on the firewall and the bottom brackets that mount the pedals. I added a piece of plate across the stays to tie it together as I was originally going to drill through the sheel metal on the other side of the firewall (where the battery sits on some models) and bolt through it, but it's more than solid enough without bolting it through here. Pretty basic design, easy to make templates and cut the plate steel. It just took a few cuts along the way to make everything clear stuff under the dash. The more detailed stuff was the throttle setup. I hate the factory throttle pedal with bushes, so I decided to bearing mount it instead. Took a few trial and error fittings as everything was good on the bench until I took it for a drive and found out that if you put your foot on the clutch while you blip the throttle, it pins the throttle open! So with that sorted and the linkage shortened, added in a bunch of mounts for throttle and clutch stops and it was pretty well done. Took hours of messing around to get it right, lots of fitting and removal, but now I know everything fits, could replicate one in a couple of hours I reckon.

Missing the top plate in that photo (which you can see below) which helps tie both sides of the pedals together so there is no flex, not even from the firewall when it's all tied in. I would certainly use thick plate for the firewall mount again, 6 or 7mm thick because it helps spread out the load across the firewall as it is weak and does flex. Everything else can be thinner like I said before.

As it stands now, I can grab a hold of the pedal box and and rock the car back and forth by it, so im not worried about it moving any time soon.

Here are the reservoirs, the lines, the hydraulic brake switch and the rear bias controller, all mounted on the other side of the firewall. Originally I just had the rubber lines come straight out of the reservoirs and through the firewall, but it's a tight fit and I was worried about kinking the hose, so I used a few 90 degree elbows to make the turn instead so the hose just comes straight in. Doesn't look too pretty with all those clamps, but it's more of a trial sort of thing to see how it works. Afterwards ill replace with brass fittings or maybe find some moulded brake hose to make the bend, but it'll do for now. Just have to tie all the lines back up again as decided to change from the plastic style clip in retainers to more sold "P" clips, using rivnuts (or nutserts) to provide locations to bolt the clips to. Better mounting and easier to tie multiple lines together, while being able to remove the clips instead of riveting them in place.

I've got a website I need to update with the detailed build because Ive done a LOT more work than is covered on it, but it'll probably be a couple weeks before that happens because im lazy and it's kind of boring updating it. hahah.Just a little project im working on

- http://www.lse30.com -Comment

-

90 bends are fine, you just have to do your flares before doing the bends. As for on car, well, it's not meant to be on car, I haven't seen a good on car one yet really. All the block style ones are average at best. Easier to pull the line out of the car than to fuck around with them, but it's obviously not for every single situation.Just a little project im working on

- http://www.lse30.com -Comment

Comment