Official Fabrication & Welding Porn Photo Thread

Collapse

X

-

-

-

We dont engineer anything. Companies send us blue prints and request quotes. We tell them how much per part. The shop i work at is whats known as a job shop. We do small runs, anywhere from a single part up to about 200. Because of the high turnover rate i get to see many different things. Youd be surprised how often youll find simple mathematical errors.

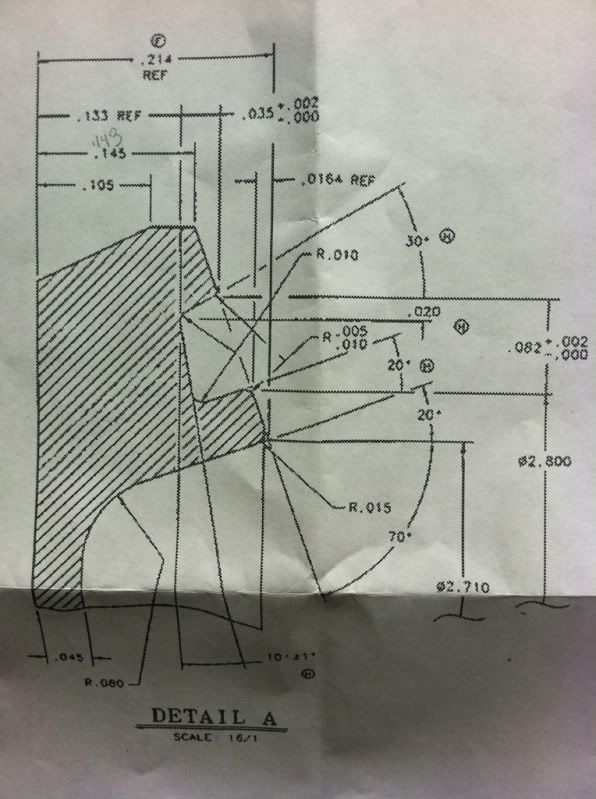

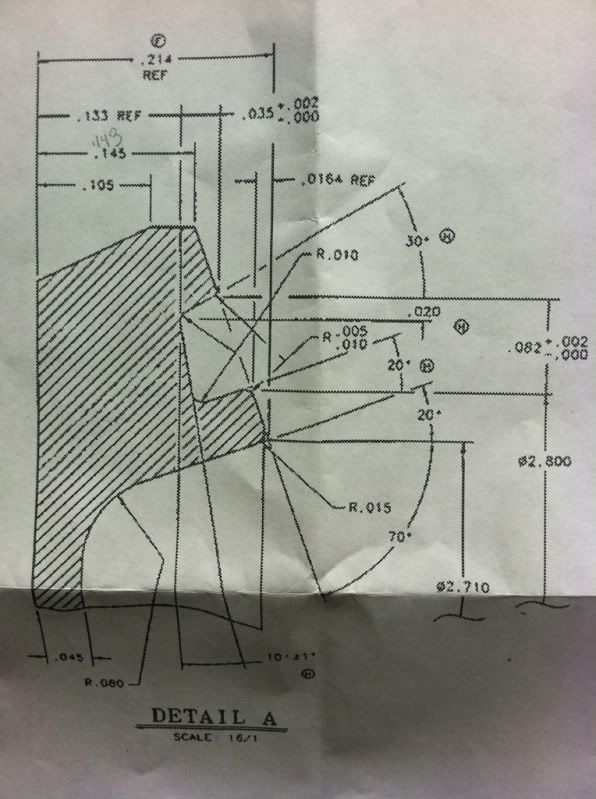

Since this is a photo thread take a look at the detail for this groove. We called the buyer and asked how they planned on measuring it so that we could do it the exact same way because there is really no good way to check it with the accuracy they have speced out.

Said groove

Time for a cmm perhaps?Leave a comment:

-

^Now what would it take to make those work on my E30...

lol jk, that looks awesome.Leave a comment:

-

-

-

-

I built some shocks today for a 996 GT3 CUP car, does that count?Leave a comment:

-

This thread makes me happier than just about any thread on R3V.

Need to see more progress on the Zorg cannon NOW.Leave a comment:

-

We dont engineer anything. Companies send us blue prints and request quotes. We tell them how much per part. The shop i work at is whats known as a job shop. We do small runs, anywhere from a single part up to about 200. Because of the high turnover rate i get to see many different things. Youd be surprised how often youll find simple mathematical errors.

Since this is a photo thread take a look at the detail for this groove. We called the buyer and asked how they planned on measuring it so that we could do it the exact same way because there is really no good way to check it with the accuracy they have speced out.

Said groove

Leave a comment:

-

Leave a comment: