Official Fabrication & Welding Porn Photo Thread

Collapse

X

-

-

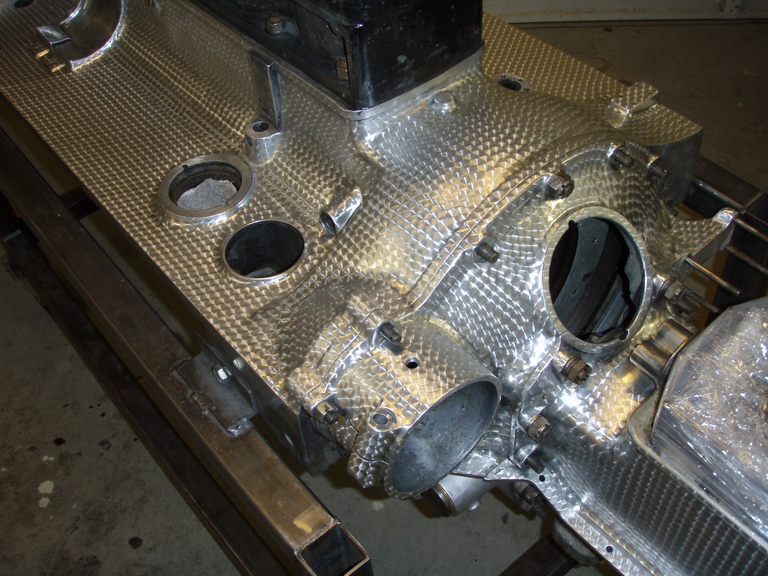

I love engine turned metal!

What is that on?

I always wanted to try it, but never had the patience to set it up in the mill.Leave a comment:

-

-

-

ok this thread needs more shit!!!! dont make me go out to the garage... =)))Leave a comment:

-

In our case, it was used for building a greenhouse/observatory for the Huntington Library Garden. The owner also wanted us to build copper pressure vessels which turned out really cool.

Yes, my work is ASME code Section 8 DivI and we also have the U, R, S, PP, and N stamps. We just got the N stamp because we will be building HSLA100 spheres where they will be detonating small bits of uranium in them.Leave a comment:

-

Here are my two piece clamps I designed and cut out on the laser at work. I didnt like anything the autoparts store had. It was either something ridiculous looking for something cast and expensive. These are .125" with a .125" backer plate. The customer had the wrong die so I had to hand form the bends. Kinda sucks but I wanted my exhaust back on this weekend.

Leave a comment:

-

-

Some of my welds. Remember nice looking welds don't add HP. Self taught no school.

I probably have made close to 100 manifolds.

My drive shaft holding 622rwtq mig

B35 mounts mig

Mig 16 gauge

Leave a comment:

-

historically, (starting in the 1830's) it was used to clad the bottom of sea going vessels because it was much cheaper than copper but contained the same anti sloughing(wont allow barnacles and algae to grow on its surface) and anti corrosion properties as the pure metal. other than being used in corrosive environments as a cheaper alternative to copper, i don't believe it has much application.Leave a comment:

-

not automotive related but Ill contribute...

I work in a shop that builds custom ASME code pressure vessels and Space Thermal vacuum simulation chambers so the weld quality needs to meet stringent requirements.

here are some pics from today:

We are building our vacuum chamber that we will be doing titanium welding in:

vacuum tight weld to hold up to 10x10^-12 Torr space vacuum

ASME code jacketed pressure vessel

ASME code pressure vessel head with an 4ft ID x11in thick flange. Head outer weld required 60 passes on the outside and 35passes on the inside with a dye penetrant check and radiograph to make sure there are no inclusions at all. The weldment had to remain heated so imagine welding in an oven...

Vacuum flange

"Un-Weldable" Munze metal, we developed a weld proceedure and are first to sucessfully weld Munze metal and get it structually certified by the state of CA

I dont do much ASME work and when I do its all B31.1 or B31.3 for piping. but mostly work with the API 1104.

I assume you guys are welding to BPVC Section 8 arent you????

I am an X-ray hand so I am the one who looks though the weldLeave a comment:

Leave a comment: