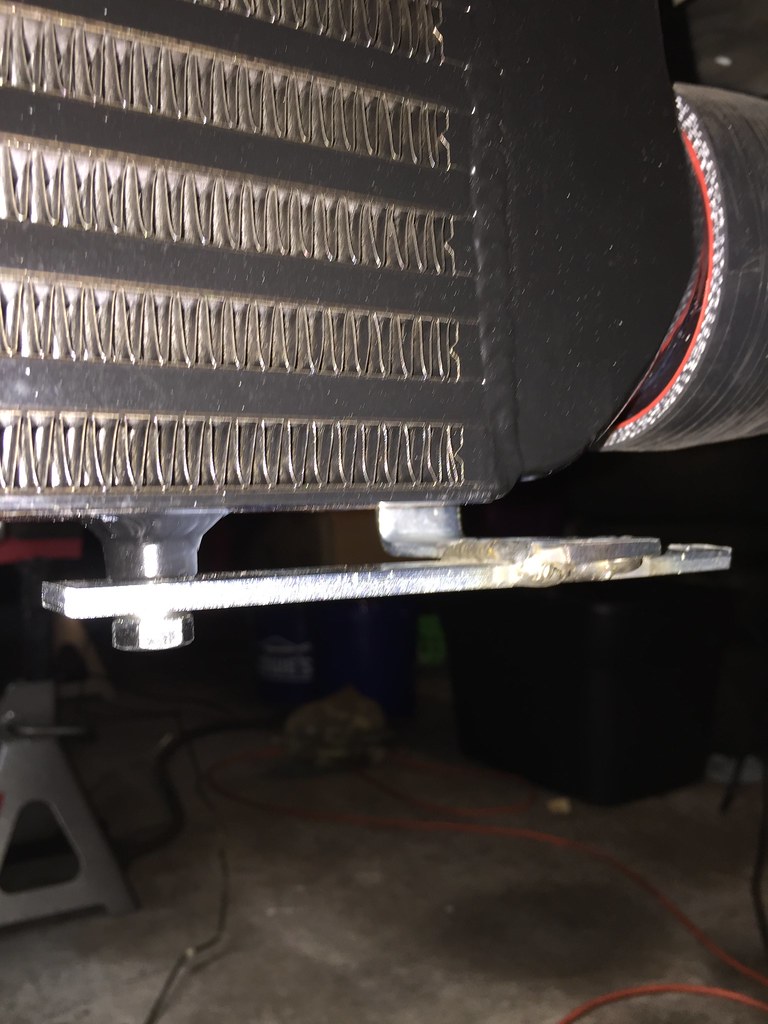

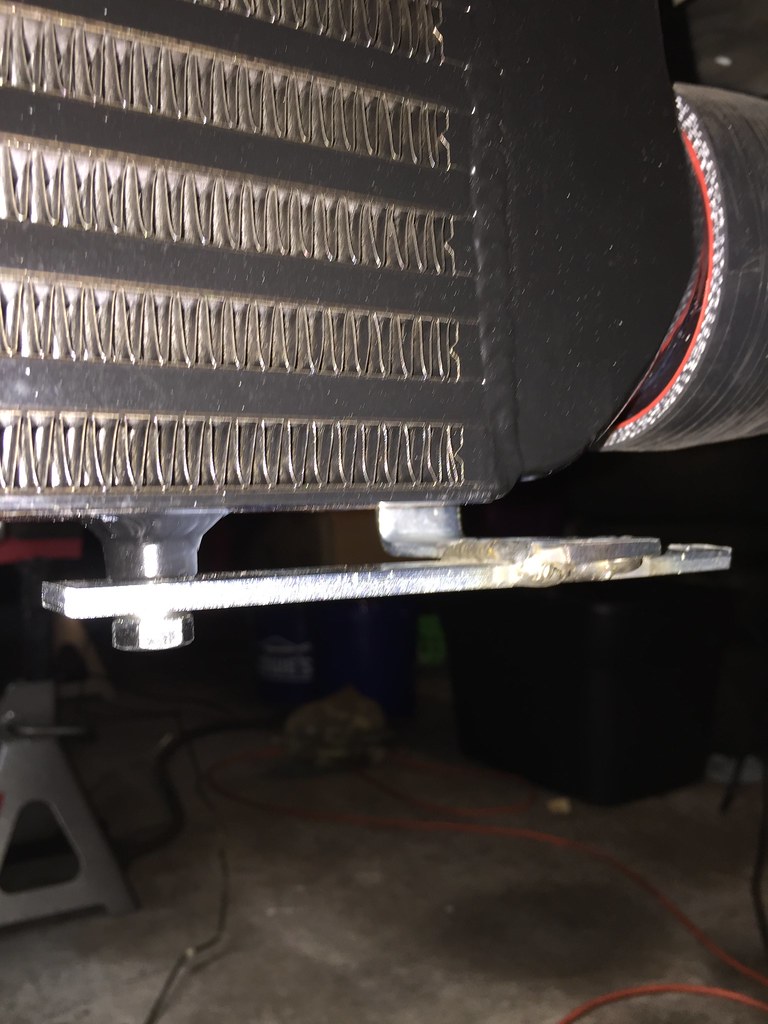

Once the rear crossmember and diff mount were complete, I towed the car back from my dad’s place for a 3-hour trip to my place in Chesapeake, VA. I went to work doing all the stuff needed before the car went for paint and bodywork. What little was left on the car came out. Only thing that stayed put was the steering column. I started by mounting the huge intercooler since I knew everything in the front of the car would have to be modified to clear it. I made a bracket for the top mount points and MIG welded it to the radiator core support. Also made a pair of brackets for the lower mounting points on the intercooler and was able to use the pre-existing holes in the core support for the M20 oil cooler to mount them. My goal was to try and minimize holes drilled and major chassis mods for everything.

E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr

I also mounted a Setrab oil cooler on top of the upper intercooler support. This sits just behind the kidney grills. The lower brackets were cleaned up by cutting the extra length off and then brought in with a large batch of stuff for powdercoat.

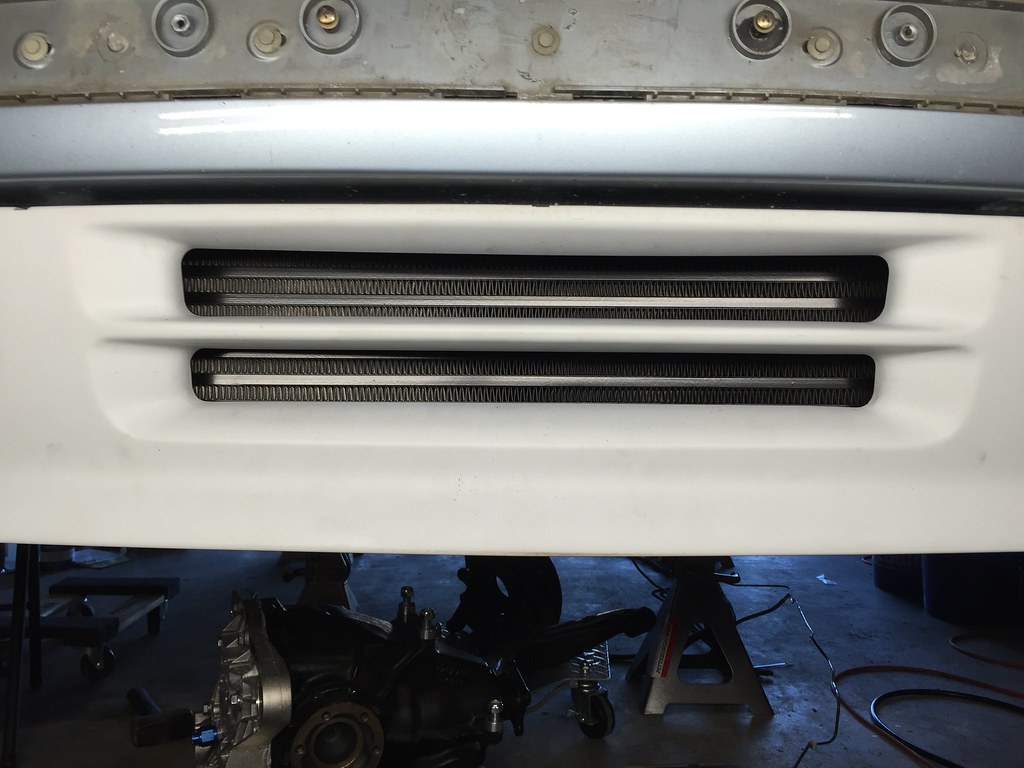

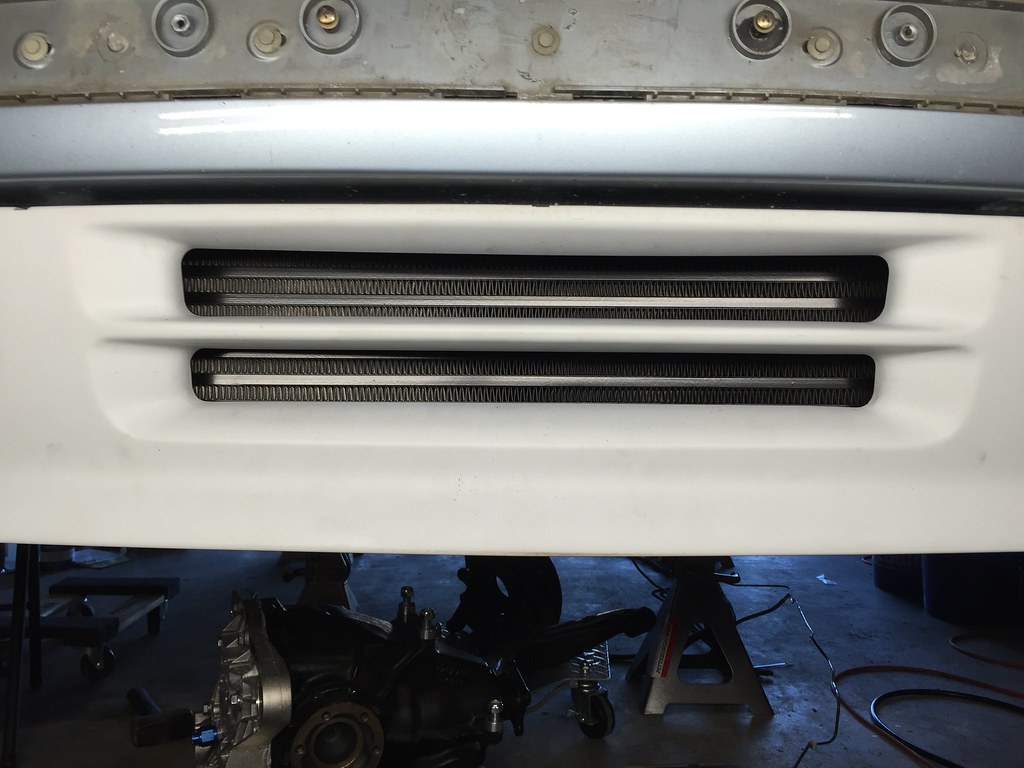

Modifying the front valance and M-tech2 lower was an enormously tedious job. Fit up, cut a little…rinse and repeat 100 times until everything had clearance. Tons of work but the results were worth it.

E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr

I also notched out the bottom of the front bumper in front of the intercooler to help get more airflow over it. Totally stealth and unseen. Not sure how much it helps but it made me feel better to do it.

E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on FlickrI also mounted a Setrab oil cooler on top of the upper intercooler support. This sits just behind the kidney grills. The lower brackets were cleaned up by cutting the extra length off and then brought in with a large batch of stuff for powdercoat.

Modifying the front valance and M-tech2 lower was an enormously tedious job. Fit up, cut a little…rinse and repeat 100 times until everything had clearance. Tons of work but the results were worth it.

E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on FlickrI also notched out the bottom of the front bumper in front of the intercooler to help get more airflow over it. Totally stealth and unseen. Not sure how much it helps but it made me feel better to do it.

E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr

Comment