Wow, you are the friggin' man!

Im sure Ill be calling you soon too

This build escalated quickly...

Collapse

X

-

You took the practical approach aha

Dont forget to ask them to modify it for use in an E30 with brake booster! I didnt even know that was a thing until they offered it.Leave a comment:

-

I am planning on going to that in the future, just wanted to get the car done first.Naturally, as I received the plenum, I had to inspect the quality control by putting my whole head inside. Everything checked out! Thankfully, every particle of my body is still connected as it should be.

Its the Karbonius CSL replica, the best OE looking CSL box imo.

Glad you like it!! I got a quote from them the other day. I have a Carbon Fiber Engine cover coming and eventually I will do that intake as well.Leave a comment:

-

I did use the shims he supplied but maybe I put them in the wrong location... I cant tell if the image you supplied is looking at the rear of the car or the front. Currently, the shims are on the front driver side bolt location.

Edit: Pretty sure the image is looking towards the back of the car. I think my shims are in the same location as pictured.

Its a shame, quality fabricator and product. Absolute trash business skills. He told me he sells insurance as a day job... Personally I think he should have quit, hired a secretary/manager to deal with the business end and focus on fabrication.Leave a comment:

-

Taking a look at your trans brace, on the defunct Acr Site it seems tyler intended for the brace to be shimmed to the chassis:

From his site. BTW anyone else, skip ArcAsylum. He is defunct and ran with peoples cores and money.

Leave a comment:

-

Naturally, as I received the plenum, I had to inspect the quality control by putting my whole head inside. Everything checked out! Thankfully, every particle of my body is still connected as it should be.

Its the Karbonius CSL replica, the best OE looking CSL box imo.Leave a comment:

-

-

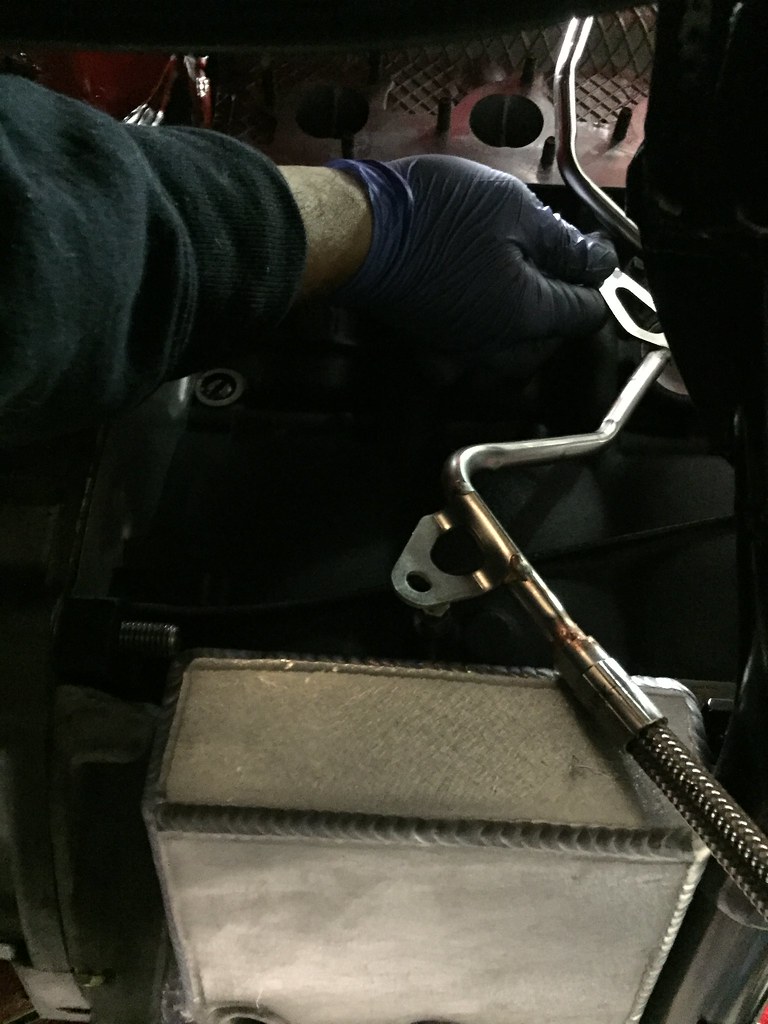

Since Tyler went MIA I was at a loss with the oil return line that he was supposed to modify... So, I had to order a new one and devise a way to shorten the line. I didnt want to use AN line since they are only rated to maybe 500F and the pipe runs through the headers.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Basically half of the hard line needs to be sectioned. The AN fitting mounts to the top section of the oil pan shown here.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Originally I was going to section the hard line, machine an appropriate tube to overlap the two sections, and then braze the tube to the two hard line ends. I wasnt comfortable using the brazing filler I had because its working temperature was 700F and I didnt want to risk it softening/flowing due to the heat of the headers. I doubt this tube sees 700F or even 500F, but I believe in do it once, do it right. I decided to take advantage of the laser welder at my work and Im very satisfied with the result. Just to make sure it was a hermetic weld I pressure tested the line and the results showed there was no leak.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

While I was in the lab at work I thought of a plan to get the E46 AC pressure sensor to work with the E30 dryer. Taking measurement of the E30 sensor I realized there might just be enough material to machine and tap the metal portion of the sensor. In the end I was even able to machine an o-ring grove that the E46 sensor utilizes. I have yet to tap the threads, but I think there is just enough wall thickness to be alright.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Ill also be running an E30 temp sensor in the lower radiator hose for the E46 AC. Simple drill and tap here using the Mishimoto hose adapter.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Back in the garage, basically have a bunch of the little systems to piece together.

New fuel filter and hoses.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

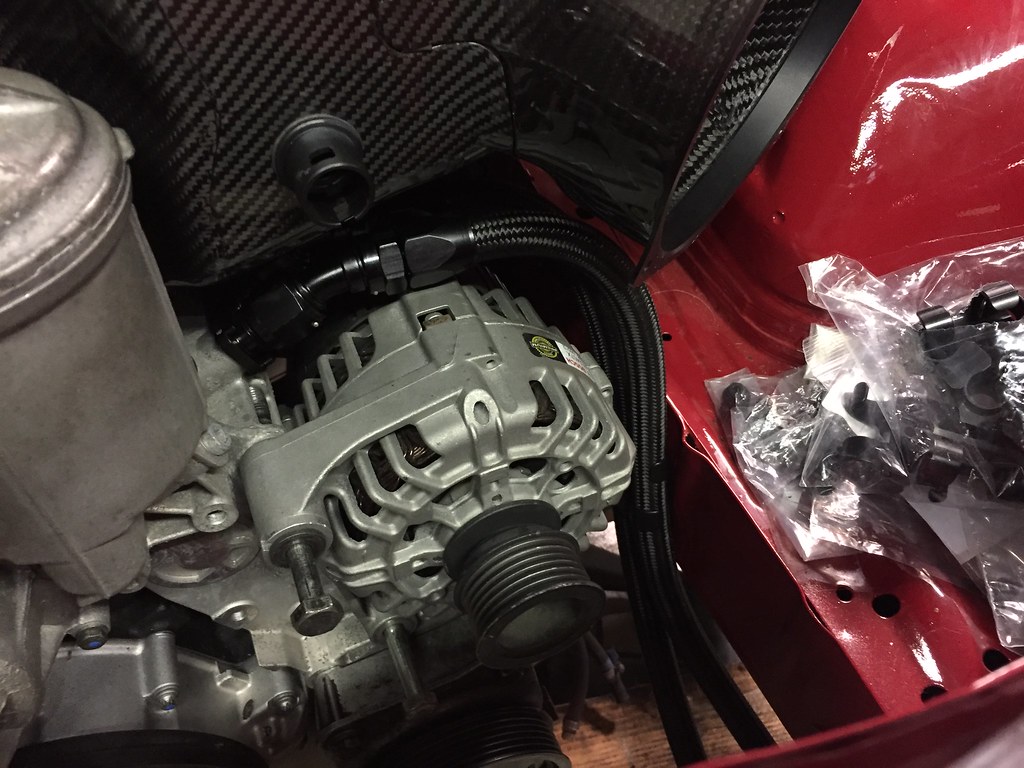

CSF oil cooler in. Used black Fragola AN bits for a low profile look.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Doesn't hang down too far for being simply routed.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Seca jumped in to join me for some work, shes wondering when this thing will be taking her to the beach!

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Porsche 944 booster modified and installed. Along with new clutch master, clutch slave, and 25mm brake master.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Clearance is tiiiight! Im gonna go back and move the booster over some.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Had to do some trimming to the wire cover, may have a little more massaging to do.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

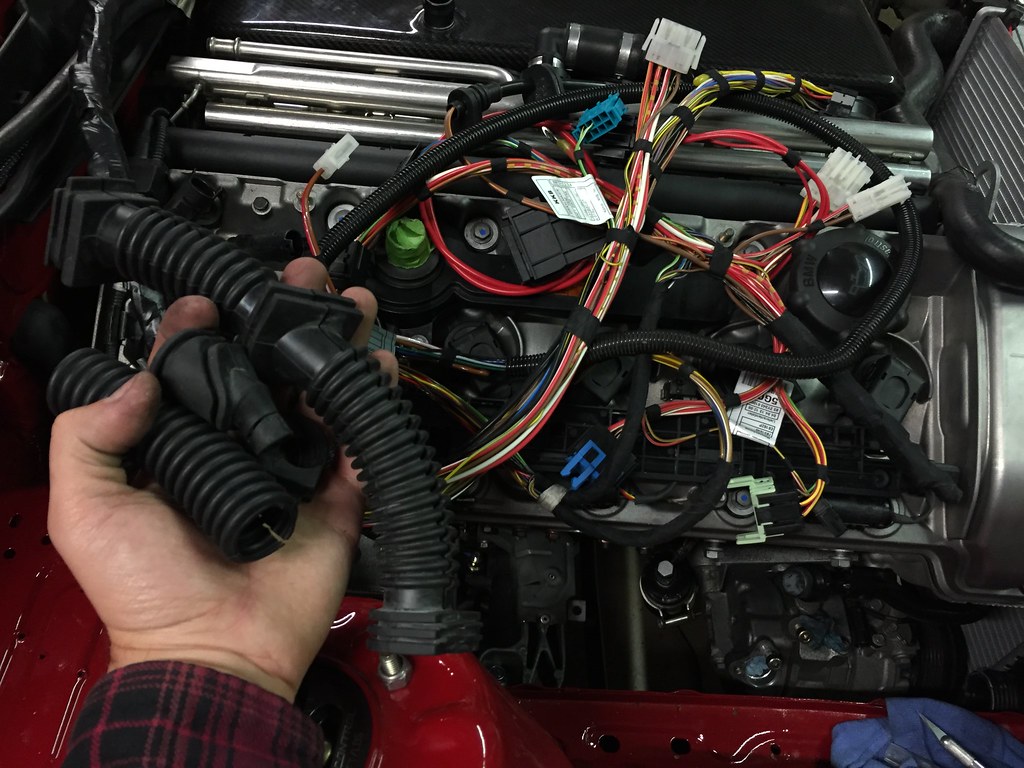

Crimped and soldered new connectors per Andrew's wring instructions.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Cut off all the chunky rubber wiring guards to tuck all the wiring through the two inch hole in the fire wall.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Going to make a cutout in the battery box wire cover for this rubber section.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Need to figure out a clean way of organizing and mount all this crap...

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

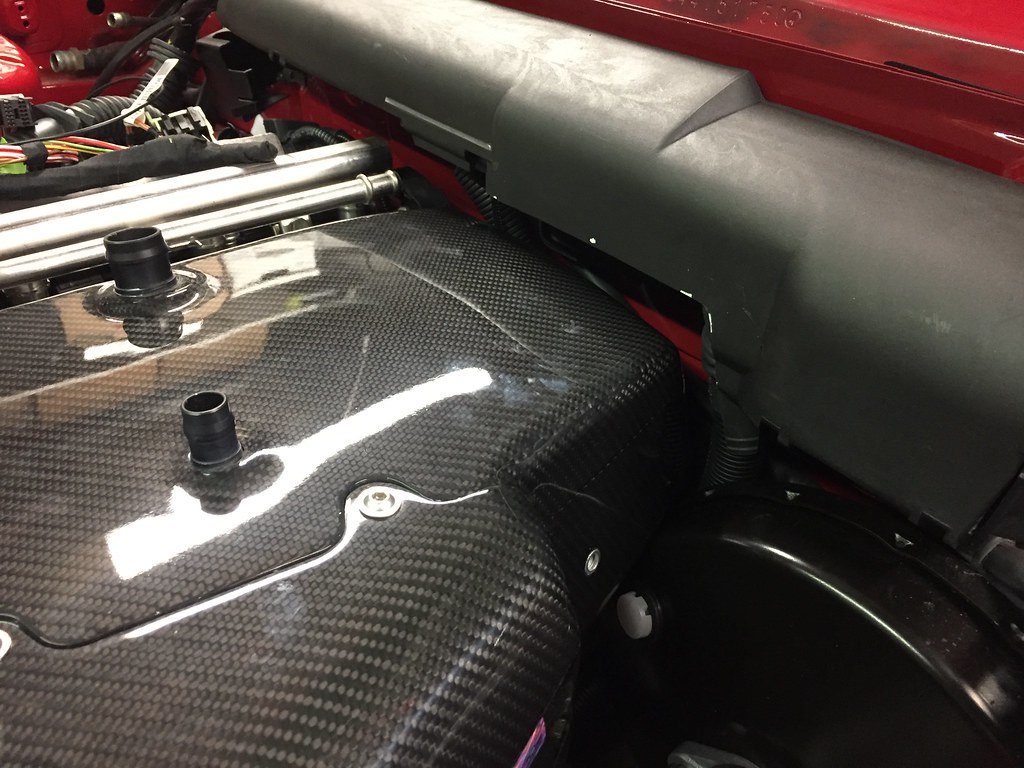

And finally, Ill finish this post with proof that the CSL airbox will fit with a 944 brake booster if the box is modified to fit in an E30 by Karbonius. Threw on all the covers to give me warm and fuzzies and motivate me to finish this shit.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

In all seriousness, the airbox was modified by Karbonius much like others modify the stock airbox to fit a booster. If you go boosterless or maybe run a small booster it should be possible to fit with a regular CSL box.Leave a comment:

-

Update tiiiiiime! Back in China for another business trip, I figure since I cant work on the car I better update the thread.

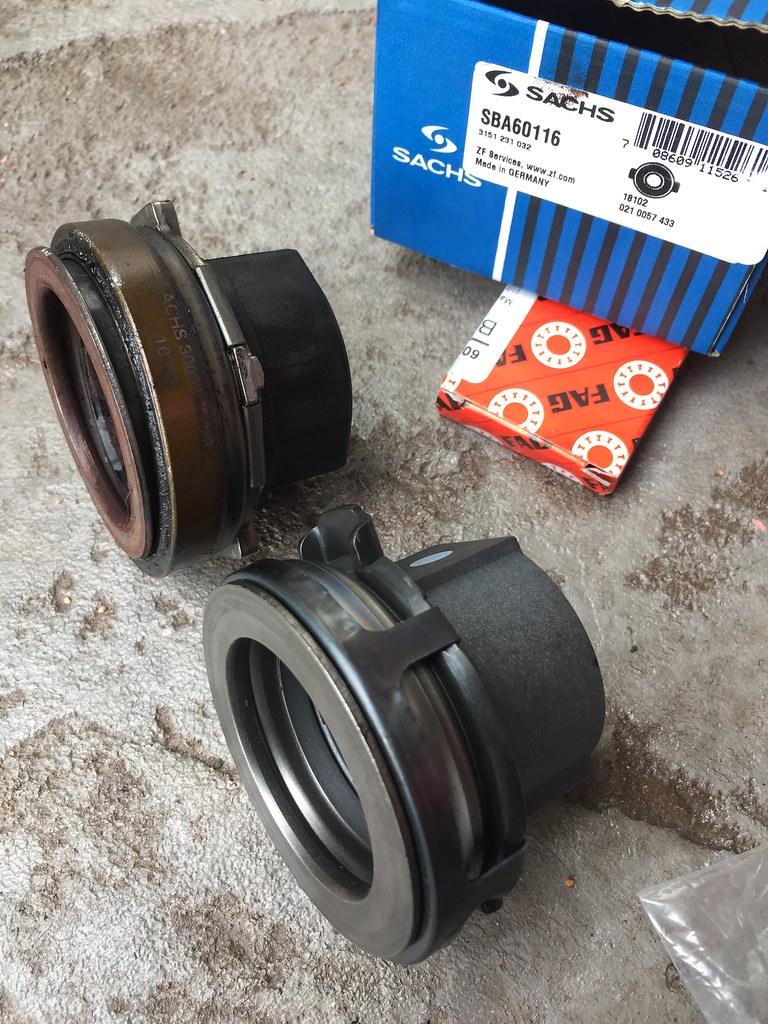

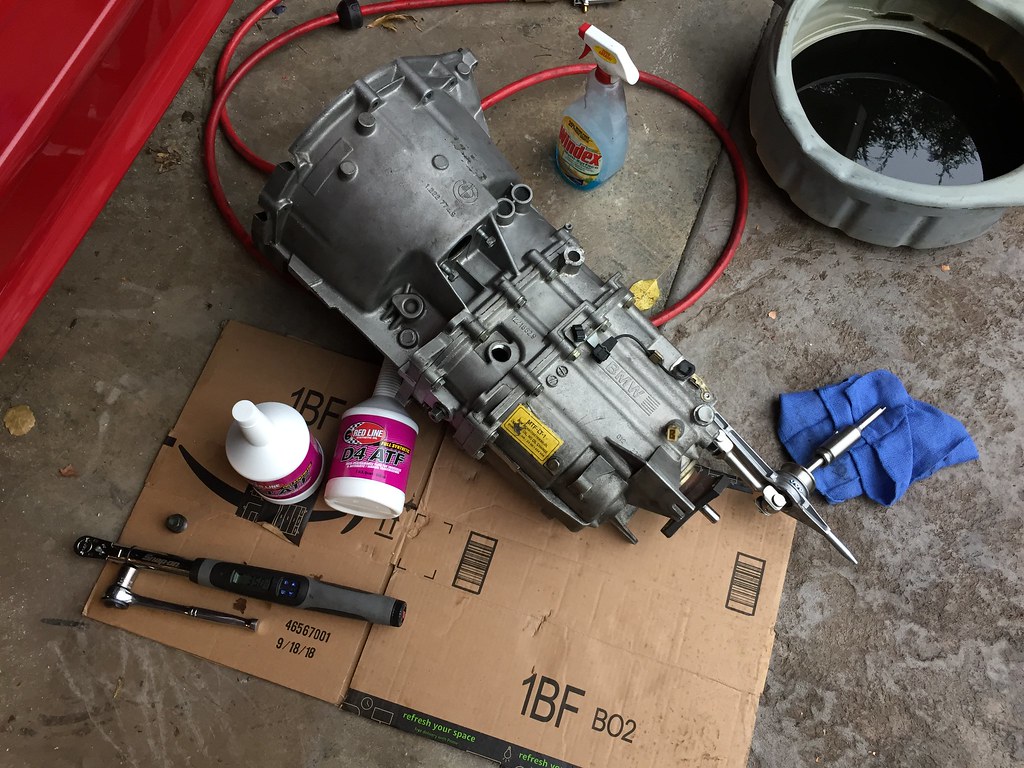

Transmission went in with all the fixins'. Decided to go with the UUC full EVO 6-speed swap shifter because it came with the Euro E36 carrier housing which was a heavy fraction of the cost to begin with.

I would highly recommend the shifter to anyone looking for an OEM style but I have to admit, not super stoked with the quality for the price. Some of the components were installed backwards and repairing it myself would void any sort of warranty, however, UUC gladly sent a new one. The main thing that bothers me is the ball cup is loose in the housing causing a lot of slop. Not a huge deal, it still feels solid but theres an initial movement before the actual shift movement. Ill have to shim around the cup with maybe 0.005" sheet metal to get rid of the slop and then it should be an amazing shift.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Transmission in! Utilized the ArcAsylum trans brace and the AKG limited E21 mounts.

I ran into a bit of a concern here: The drivers side bushing in the photo was under tension while the passenger was under compression, as it should be. I attempted adjusting/loosening the engine mounts to get everything to fall into place but once everything was tightened down again I was left with the same result. So, Im not sure if this has to do with the AKG mounts or the ArcAsylum brace. I ended up shimming the drivers side mount so its not under so much tension. It seems like the driveshaft is straight which leads me to believe maybe it is just the trans brace.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

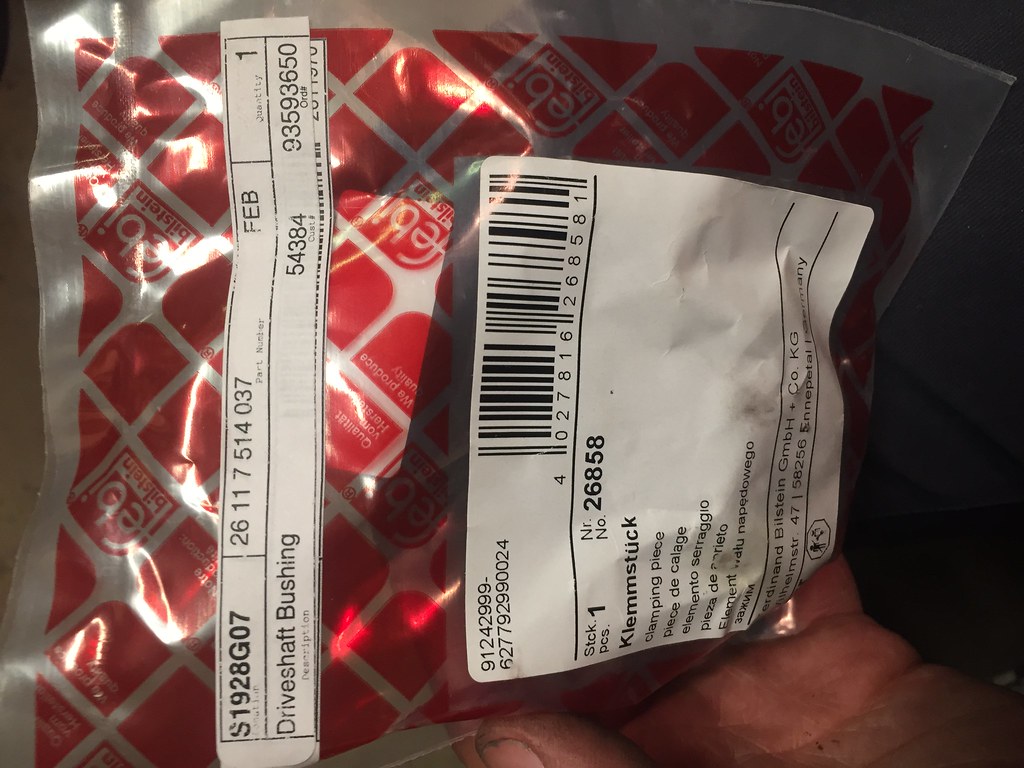

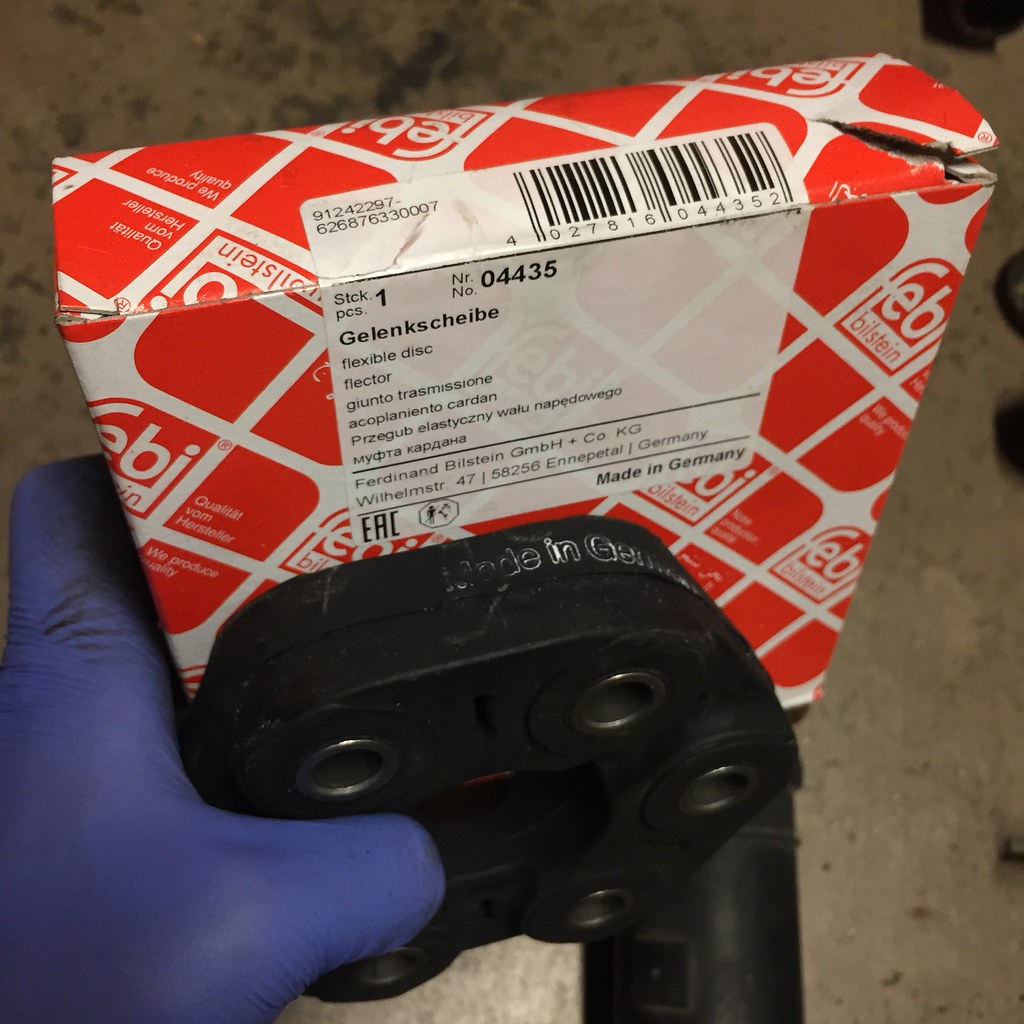

Ordered an auto E36M driveshaft off eBay, came in one piece with alignment markings but needed some elbow grease.

by Evan Nessim, on Flickr

by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

The length locking nut crumbled to bits! Was able to track down the part numbers for a new one.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

by Evan Nessim, on Flickr

by Evan Nessim, on Flickr

by Evan Nessim, on Flickr

by Evan Nessim, on Flickr

by Evan Nessim, on Flickr

by Evan Nessim, on Flickr

Very excited for this little pumpkin! A member here and local diff building wizard, WanganStyle, crafted this 3.91 diff. Its basically full lock on corner exit and open on corner entry. I had the same setup on my E36 track car turning it from weekend track warrior to wannabe drift king. With the stock LSD it was much more difficult to catch the tail if it slipped out causing a spin. With this diff the car damn near drove itself if it caught over steer. Extremely confidence inspiring! He even had a finned cover laying around, popped an AKG 85A diff bushing in and sealed it with Honda bond. Theres gotta be a reason they never leak, right?

by Evan Nessim, on Flickr

by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

And for the last bit of drive line fun, axles in, and finally got the rear brakes on. With great power comes great stopping power. Not that BMWs really make THAT much power...

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Leave a comment:

-

I purchased a TIS/WDS CD on ebay for like $10. It runs the old school BMW WDS software on a virtual machine running XP. I think the newTIS site might still work,and there is also a WDS android app, but neither are as easy to work with as the PC version from my experience. My only gripe is that the photos of the connectors aren't there on mine for some reason. The diagrams work fine though.Last edited by R3VM3UP; 12-17-2018, 03:31 PM.Leave a comment:

-

I’d agree with that assumption, where do you find the WDS? Couldint find E46M diagrams anywhere.

Need to compare my wires to your information. From my picture it looks like the wire on the right may be slightly smaller. It is indeed an E46M, convertible if that matters.

Thanks for the break down. I understand the general idea, but I am more mechanically enclined than electrical. I can solder and have the basic understanding of how simple systems work but this CAN thing is a little over my head aha I’ll definetly keep you in mind as I’m still trying to figure this out while I chip away at other projects. Think I really just need to consult with the big man himself. Maybe I can drag GPeterson here for some real answers.Leave a comment:

-

I'm not really sure the exact wiring of the fan control box. I assume that two of the wires are power and ground and the other is the signal from the DME. WDS seems to indicate that there are 2 10awg wires and 1 20awg wire going to the electric fan on the E46 M3.

1x 10awg wire RT/BL coming from a 50A fuse

1X 10awg wire BR going to ground

1X 20awg wire SW/GN going to pin 4 on X60004 on the DME.

I'm not sure that matches your fan controller exactly. It looks like you have 3 heavier gauge wires on yours. Is it from an E46 M3?

I'm not sure how familiar you are with CAN, but it is a serial communication bus that allows for multiple nodes on the bus to communicate with one another over a shared set of 2 wires. This means that you don't need individual wires carrying analog signals between every module, instead it lets you put dozens (hundreds in some cases) of messages on 2 wires. Certain functions in the E46were controlled via CAN including AC control, the DME -> cluster communication, etc. In a nutshell though, GPeterson's CAN module allows you to recreate this functionality outside of the E46 chassis by translating key analog signals into CAN messages that the DME and other modules are expecting to see on the bus. I'm not using any CAN functionality in my build, so I'm not really the best person to ask about the specifics. I do however have a fair bit of professional experience working with CAN so if you have any general questions I may be able to help.Leave a comment:

Leave a comment: