Originally posted by 2mAn

View Post

Announcement

Collapse

No announcement yet.

After a year of searching, an Alpineweiß story

Collapse

X

-

I had problem with my struts.

The welds penetrated the inside of the struts

Thanks to Ross for letting me use his bilsteins to test

fit my strut tubes and Tyler and roland for helping me grind down the welds.

Ended up using a dremel with a sanding drum and an extension.

Also used a half moon file

Finally it fits!

Installed new hubs.

Tightened down to the proper torque with the parts not on the car was a challenge.

I bolts the struts into a bench vice. Had a friend push on the strut while i turned the torque wrench towards him. It would litteraly

Move the vice and the whole bench.

Wearing my SoCal e30 shirt

Had a hard time holding

The strut to

Install

The new shock glad nut.

It's just awkward the strut wants to rotate.

So I bolted the strut to my spare wheel that keeps it from rotating.

Soo much better

Thank you to Richard at michaelgelos for letting me use the bilstein tool for the gland nut.

So much easier to Use than channel locks.

Almost done.

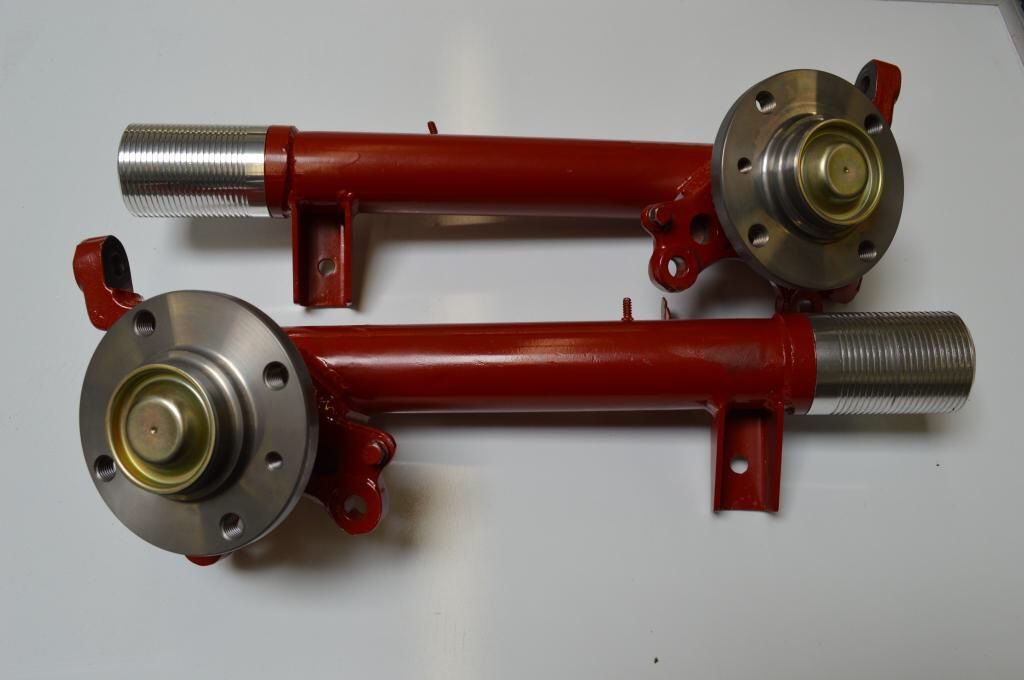

E30 strut

Stock backing plates cut out

Lower spring perch cut off

Coilover ring welded on to support the sleeve

M3 sway bar bracket welded on

Gusset welded on from. Knuckle to strut tube

New wheel bearings.

Carbon fiber brake ducts

Comparing the old strut to the new strut

No gusset and a heavy backing plate

Comparing lower spring perch

Comparing backing plate

Comment

-

With the new struts on the car I ran into an issue with the sway bar end links.

They were too long.

They have a wrench flat machined into it and it was close to the edge of the end link. It was to close to the right hand thread side of the link. And since I didn't have a left hand tap in a 3/8-24 i had to cut the links shorter on the right hand thread side and I lost the wrench flat.

Garagistic adjustable end links.

I was given these and was aware that they were long that's what I wanted, so I can cut them down to the size I wanted.

I cut an inch off the links.

And retapped a new thread into it.

Holding the end links in the cnc indexer to machine new wrench flats for a 13mm wrench.

Woo hoo one side rotate it 180 degrees at the same height and do the other side.

Finished product. You can see the little black piece of the endlink that's how much I cut off.

And the wrench fits the wrench flats I machined.

Comment

-

I love having access to all of these machines and tools. I don't take it for granted.Originally posted by 2mAn View PostI wish I had access to those toys. Lucky guy... Nice work

Comment

-

:up:Originally posted by iwantspeed View PostI had problem with my struts.

The welds penetrated the inside of the struts

Thanks to Ross for letting me use his bilsteins to test

fit my strut tubes and Tyler and roland for helping me grind down the welds.

Ended up using a dremel with a sanding drum and an extension.

Also used a half moon file

Finally it fits!1989 325i coupe 5MT Alpine White

2003.5 M3 coupe 6MT Silver Gray

Comment

-

:hitler:ThanksOriginally posted by Vanilla Gorilla View PostLooking so good dude!

ThanksOriginally posted by TeXJ View Postnice and detailed, great job.

ThanksOriginally posted by Bullwings View PostNice work, easily one of my favorite e30 build threads if not my favorite.

And holy crap on the caster!!! that's a lot of caster!

I love caster.

If I get camber plates in the future I can dial in the caster and camber and get them even on both sides

I love how she drives right now

Comment

-

Comment