The complete repair, rebuild, repaint, and v8 swap of my early model sedan

Collapse

X

-

Please tell me you replaced the rear water passage cover gasket? Hope it ends up being something simple. -

I've always loved your car. Can't wait to hear it running with the new engine!Leave a comment:

-

Nice job, Justin! hope you do not have many more gremlins to deal with on this.Leave a comment:

-

I got the engine fired up this morning. Runs perfect, just like the stock m60. No strange noises from what I can tell (although with open headers, I'm not sure id hear anything other then a rod punching a hole in the block haha).

Unfortunately, it appears to be leaking coolant. Very unfortunately, it appears to be leaking coolant from in between the engine and trans, possibly from the rear block cover. I really don't want to pull the engine back out :(Leave a comment:

-

The last m60 was really on borrowed time, good timing on your part. That 4.4 is looking really niceLeave a comment:

-

Yep. Definitely helps to have a spare tray... You can cut out the center area, bolt the outside area to the shortened stands, and then reach in and tack the stands in place while holding the tray at the correct height.

Or, cut holes in the pan, allow the stands to protrude through the holes, cut them flush, and weld. But that adds another opportunity for leaks. Here's one that was done like that:

Leave a comment:

-

-

incredible work. i can't even begin to imagine how hard it is to make mods like that without damaging the piece.Leave a comment:

-

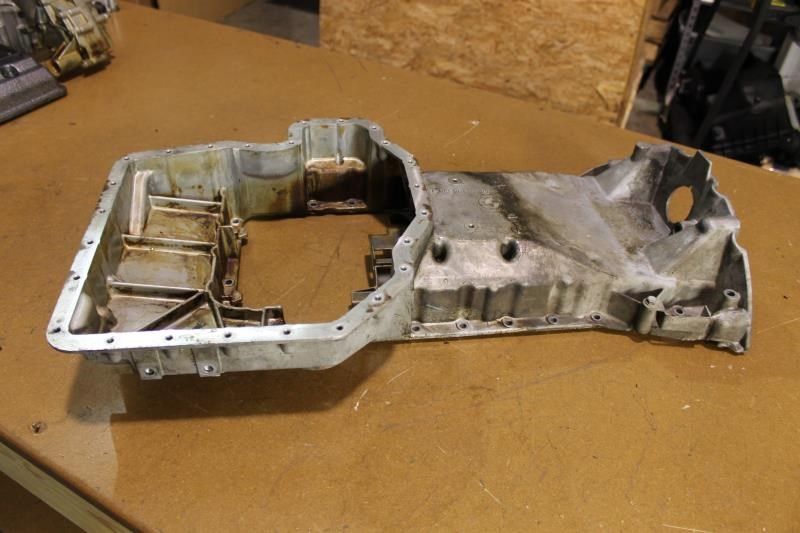

My buddy finished up my oil pan, and did a hell of a job. Ended up having to bolt it to my spare block during welding in order to prevent it from cracking, as no amount of preheating or slow cooling would prevent it from warping and cracking the weld while cooling. Definitely an involved project that requires some welding/fab skill.

Stock pan:

Modified pan, with about 1" removed from the area above the steering rack:

Leave a comment:

-

Got the trans brace finished:

Also got my driveshaft back from the shop. This was a rebuilt stock e30 shaft that I bought from another member here, with 10k miles on it. Whoever rebuilt it put grease fittings on it, which is nice. I send it to the shop to weld the 540i flange on it and balance it. Total overall cost for the fully rebuilt and modified driveshaft, all of the shipping, etc... was $300. Not bad!

Also got my subframe modified to provide clearance for the engine with the new mounts/oil pan. The e36 rack is much thinner then the e30 rack at the mounting points, so I was using spacers. I removed those spacers, which allowed me to cut those upper mounts off and weld them on lower, which provides me with all of the clearance that I need.

I also removed my subframe spacers and shortened my steering linkage. Once I get my oil pan back and installed, the engine is ready to drop in. I'm ordering my new SPEC stage 1 540i clutch today ($$$ ouch). I really hope to get this thing running by the end of the month, but I'm pretty much waiting on the oil pan at this point. My friend that's welding it is having some issues with it cracking at the weld as it's cooling, so that's the major roadblock at this point.Leave a comment:

-

Still plugging away at this daily. Got my new engine mounts made. These lower the engine 3/4" (19mm) from the "norm". My oil pan is being notched about 1", so this will give me a 1/4", or about 6mm, of clearance from what I currently have. Which is about 1-2mm. So that's one major benefit. But, I also won't have subframe spacers, which will get my bump steer and body height back where it should be. Not that this was a huge issue, but I'm able to address it fairly easily/cheaply, so why not?

Also started working on the trans brace extensions. I just cut out some 1/4" steel plate. I'm going to triangulate them a bit, but otherwise they work great! It's a bit tricky to get these right, as the brace is angled, and I don't want the extensions on a bad angle or I'll pull the thin body sheet metal apart.

Cool shot down the center of the engine!

I tried all of the local driveshaft shops to see if they could get the 540i flange welded onto the e30 driveshaft, and balanced. Nobody could do it. Ryan in VA hooked me up with his local shop who did the same thing, and they agreed to do it. So I shipped the shaft out today, hopefully that all goes smoothly, as I'm literally out of budget, and still have the buy the $600 clutch I need for the 420g and light weight flywheel.

My original hopes of having the car up and running for my 29th bday and my cars 30th bday at the end of this month (just a few days apart) are fading away. Oh well. I'll at least get hammered and sit in the drivers seat reminiscing about the past 13 years of driving it. My girlfriend supports my 2nd relationship with it, maybe she'll even join me!Leave a comment:

-

Holy moly! AMAZING build!!! just went threw all 57 pages! KEEP up the good work!Leave a comment:

Leave a comment: