Got my e32 brake booster painted and installed.

Decided to install with the spacer and use a remote reservoir instead of screwing with shortening the push rod and all that other fun stuff.

Also pictured is the new e32 master with 2002 master grommets and nipples.

Not purchased yet is the e36 brake booster check valve. It's situated right on the booster so no need for extra length of hose, hose clamps etc.

Next tackled my leaky steering rack.

Rack is from rack doctor, nicely painted and fresh.

This was a much bigger pain in the ass with the motor installed, though it went in without too much trouble.

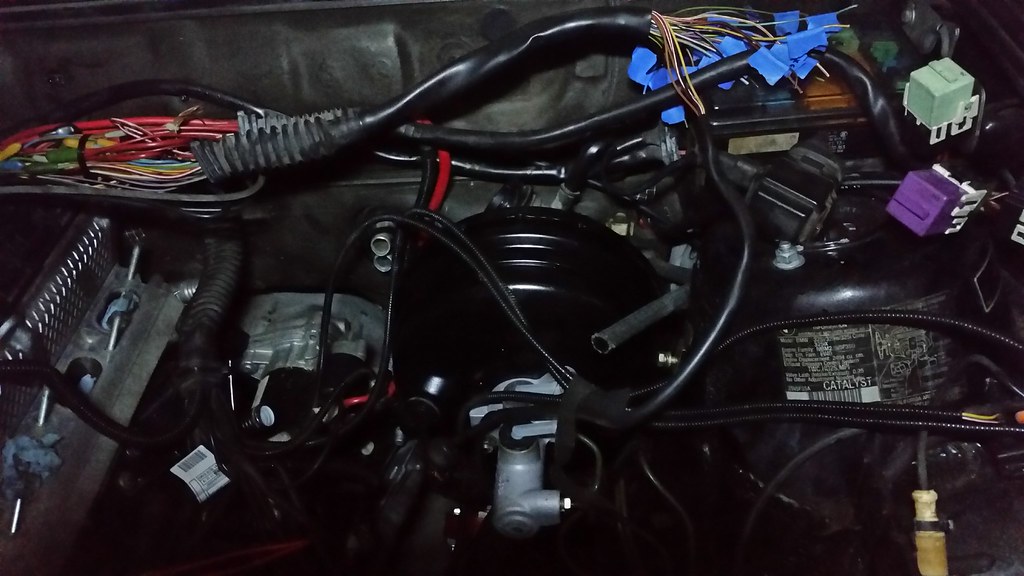

Lastly did a bit of wiring and clean up to wrap things up.

Nothing too exciting but I did start fitting the harness cover so I now know exactly where to wire my c101 and how to route everything.

Here's how she sits now.

Coming up next:

Power steering pump clean/rebuild/install.

Install all hoses under the intake.

Intake manifold.

C101 wiring, wire routing, podi.ca gauge install.

Start planning out emissions equipment installation.

Spent several hours with a borescope and piece of wire trying to remove it which only made it harder to get to in the end. For future reference... when removing the old detent bearing sleeves, peel away one side at a time. Peeling both sides at once will make the sleeve very very stuck and you will end up kicking yourself repeatedly.

Spent several hours with a borescope and piece of wire trying to remove it which only made it harder to get to in the end. For future reference... when removing the old detent bearing sleeves, peel away one side at a time. Peeling both sides at once will make the sleeve very very stuck and you will end up kicking yourself repeatedly.

Leave a comment: