RESTORATION DESIGN'S FIRST BMW

www.restoration-design.com

Say hello to our new (old) 1972 BMW 1802!

LADIES AND GENTLEMAN...

We are Restoration Design and, quite simply, we make sheet metal auto parts. We've made a name for ourselves in the Porsche world with our exceptionally accurate fitments and high quality and now we're going to do it again with BMW.

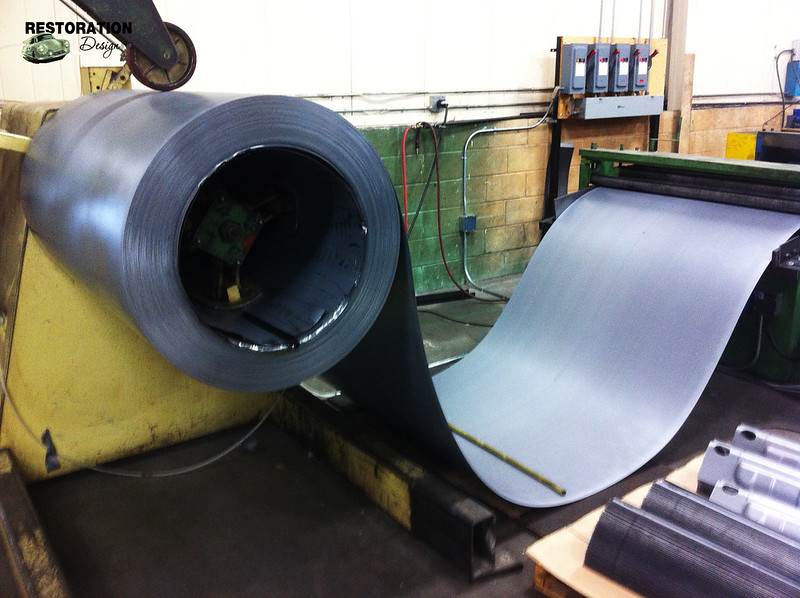

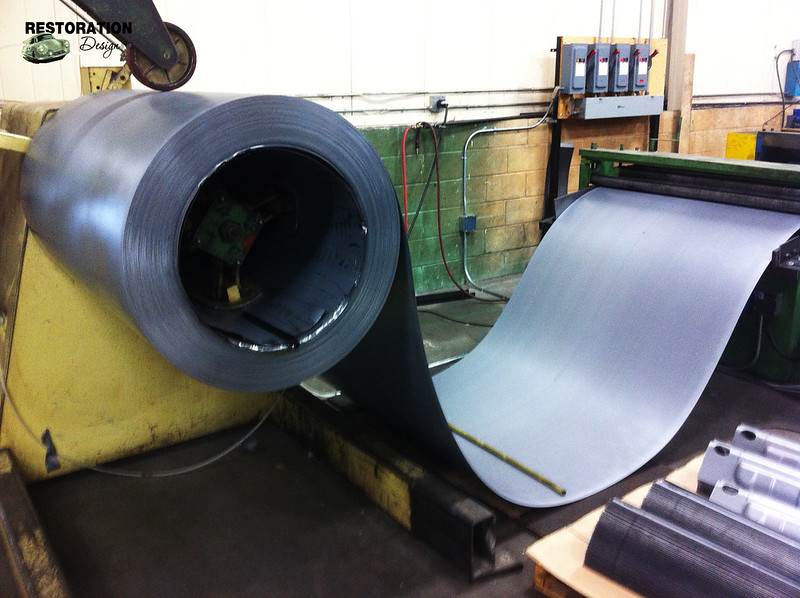

Here is where the parts start out!

Here is where we stamp out some of the parts!

Here is where we store the parts!

Here is the humble aisle where my (few) BMW parts reside!

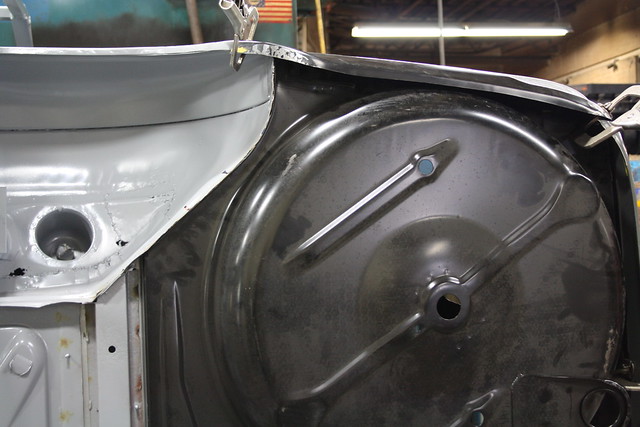

And eventually our parts can find themselves restoring some pretty great cars! For example, here's one of our cars here.

The egg plant 1952 Porsche 356 Pre-A! A very rare car indeed!

BACK TO THE BMW!!

We got it into the shop and began to pull it apart. Interior, engine, electrical, etc...it all has to come out!!

So as you can see, it's in pretty good shape. However, we all know that a car that is pushing 40 years old is rust, rust and RUST!!

Either way, we managed to pull the engine out. I wish I had the photo, but we used a forklift! xD

Classic roundie!

Like every E30 I've ever worked on, this subframe was SERIOUSLY stuck.

Deciding what to do with this engine...so many options!

And I'll leave you with this parting shot, right before it was sent off to be sandblasted. Poor girl, looking rather dead on her side!

Say hello to our new (old) 1972 BMW 1802!

LADIES AND GENTLEMAN...

We are Restoration Design and, quite simply, we make sheet metal auto parts. We've made a name for ourselves in the Porsche world with our exceptionally accurate fitments and high quality and now we're going to do it again with BMW.

Here is where the parts start out!

Here is where we stamp out some of the parts!

Here is where we store the parts!

Here is the humble aisle where my (few) BMW parts reside!

And eventually our parts can find themselves restoring some pretty great cars! For example, here's one of our cars here.

The egg plant 1952 Porsche 356 Pre-A! A very rare car indeed!

BACK TO THE BMW!!

We got it into the shop and began to pull it apart. Interior, engine, electrical, etc...it all has to come out!!

So as you can see, it's in pretty good shape. However, we all know that a car that is pushing 40 years old is rust, rust and RUST!!

Either way, we managed to pull the engine out. I wish I had the photo, but we used a forklift! xD

Classic roundie!

Like every E30 I've ever worked on, this subframe was SERIOUSLY stuck.

Deciding what to do with this engine...so many options!

And I'll leave you with this parting shot, right before it was sent off to be sandblasted. Poor girl, looking rather dead on her side!

Comment