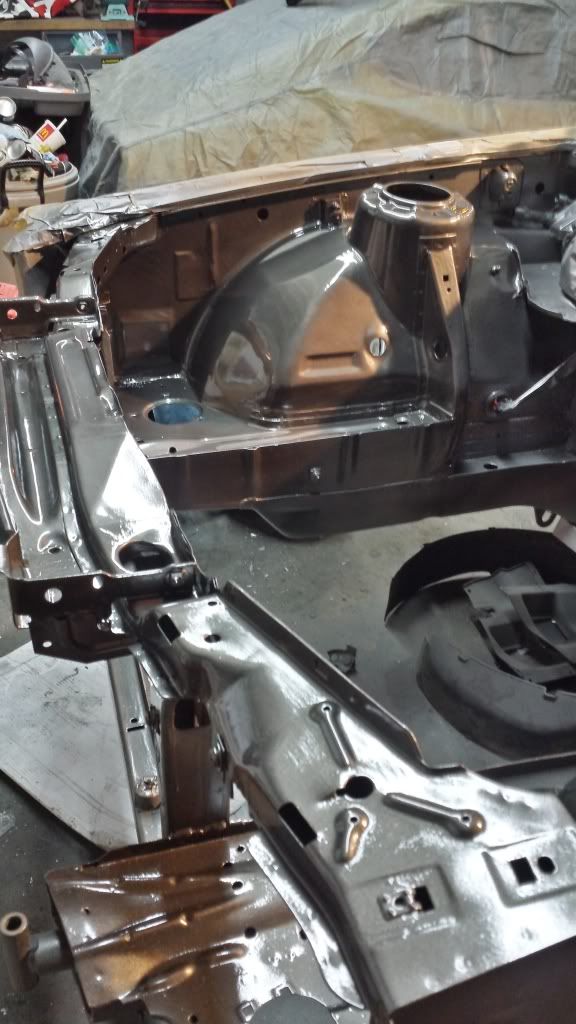

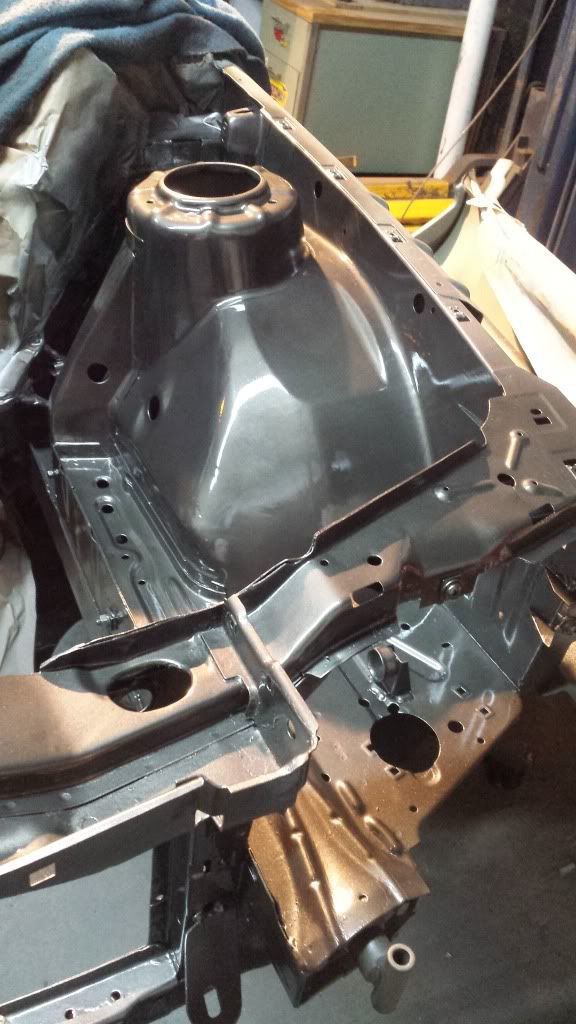

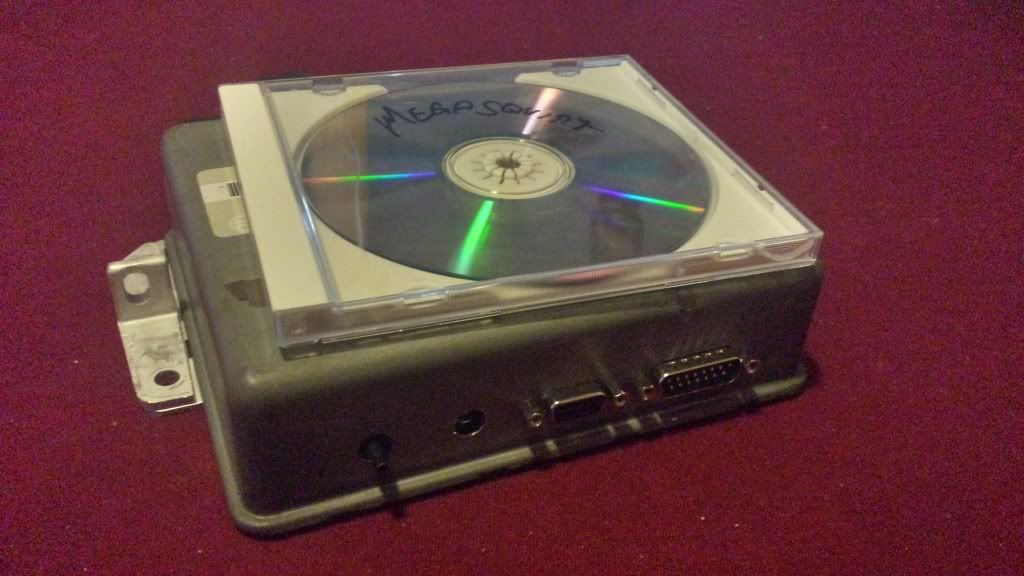

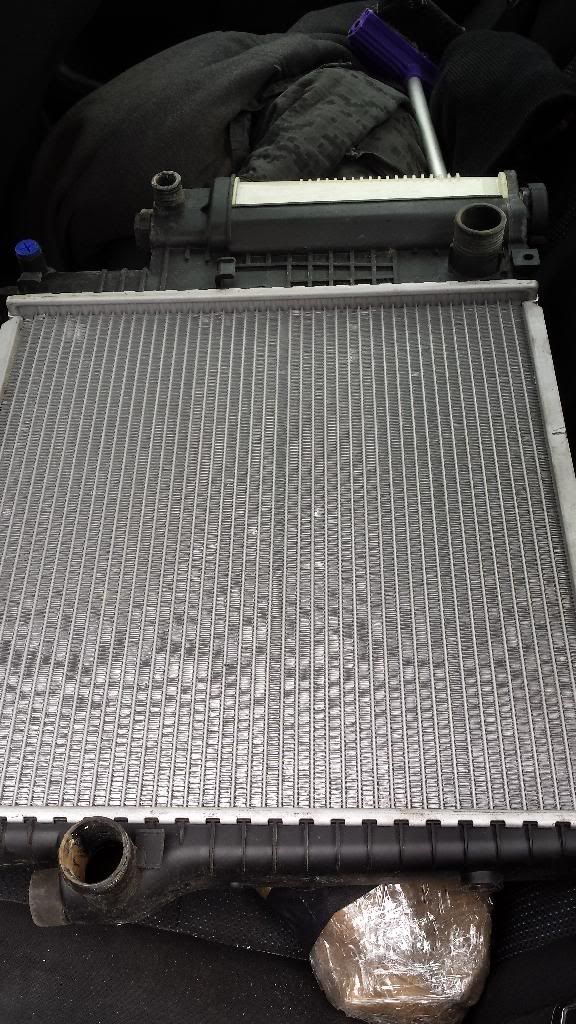

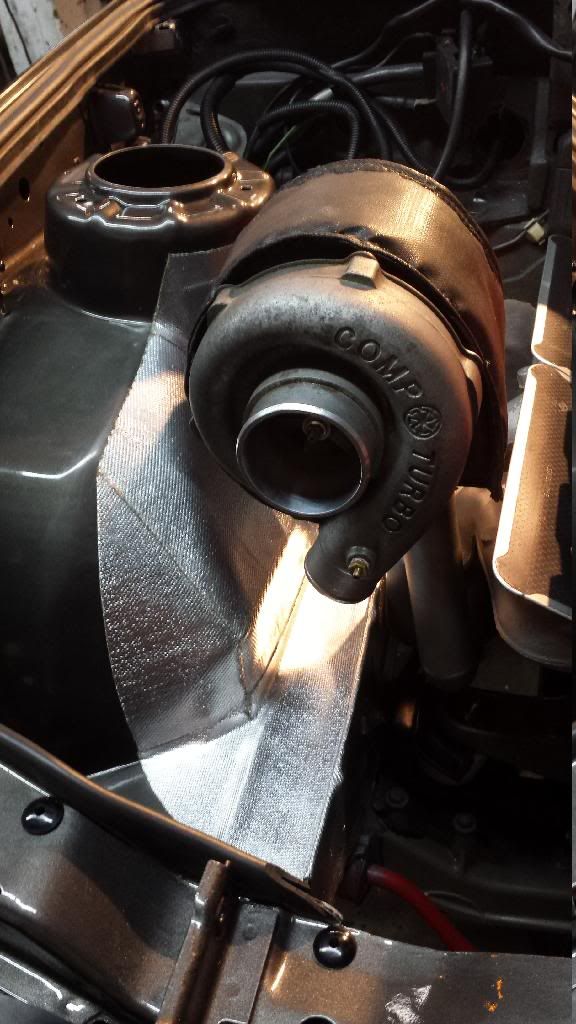

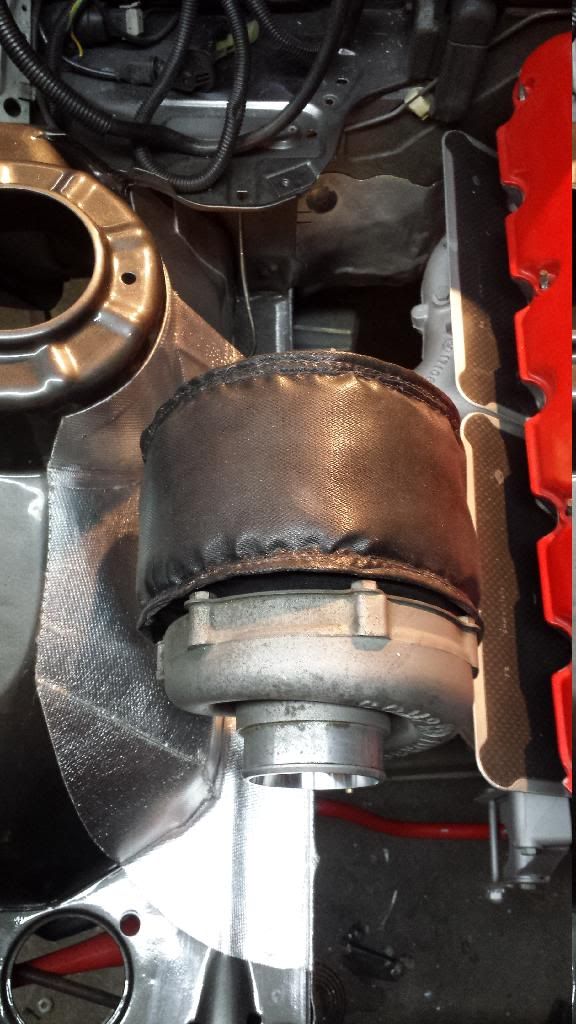

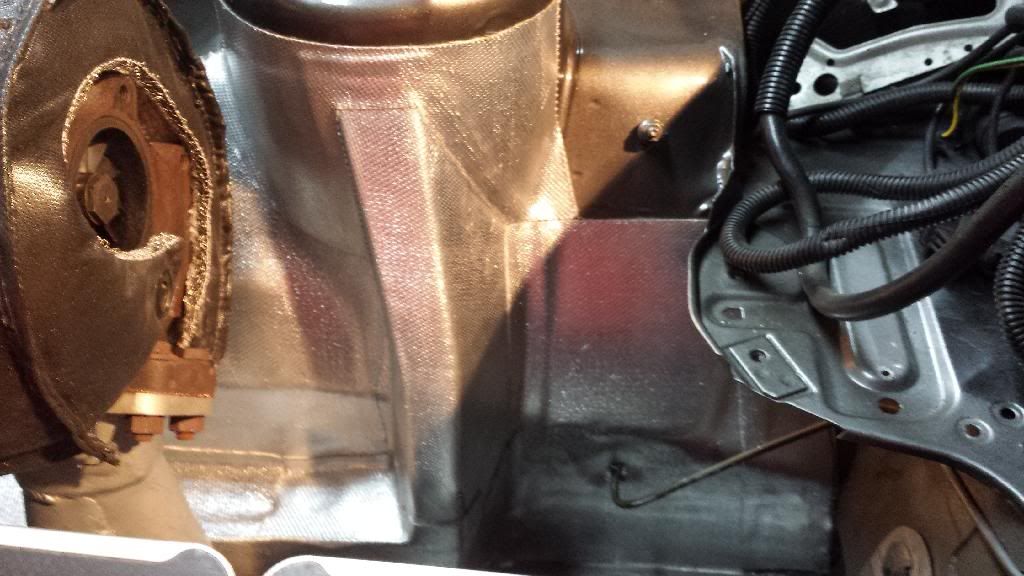

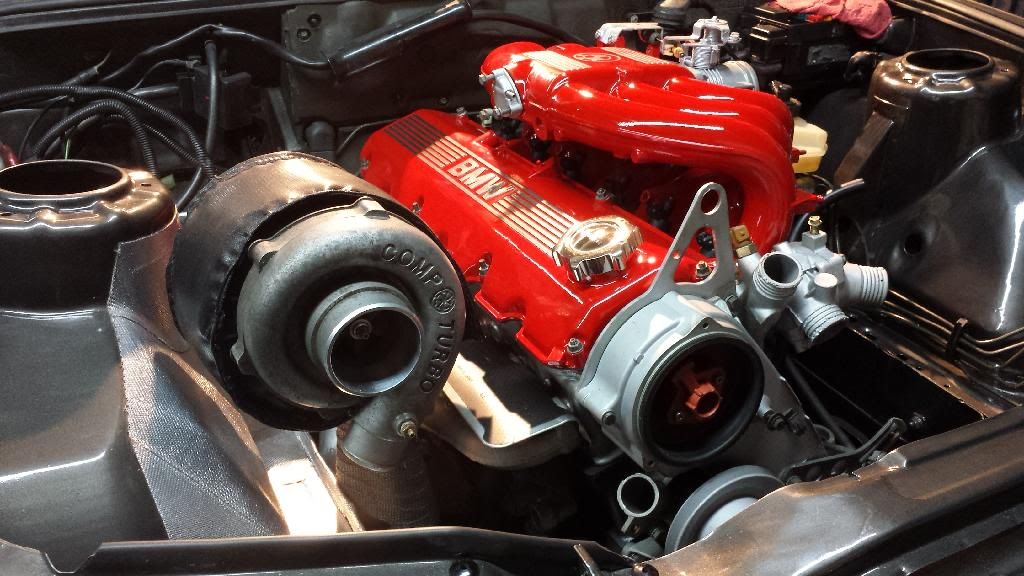

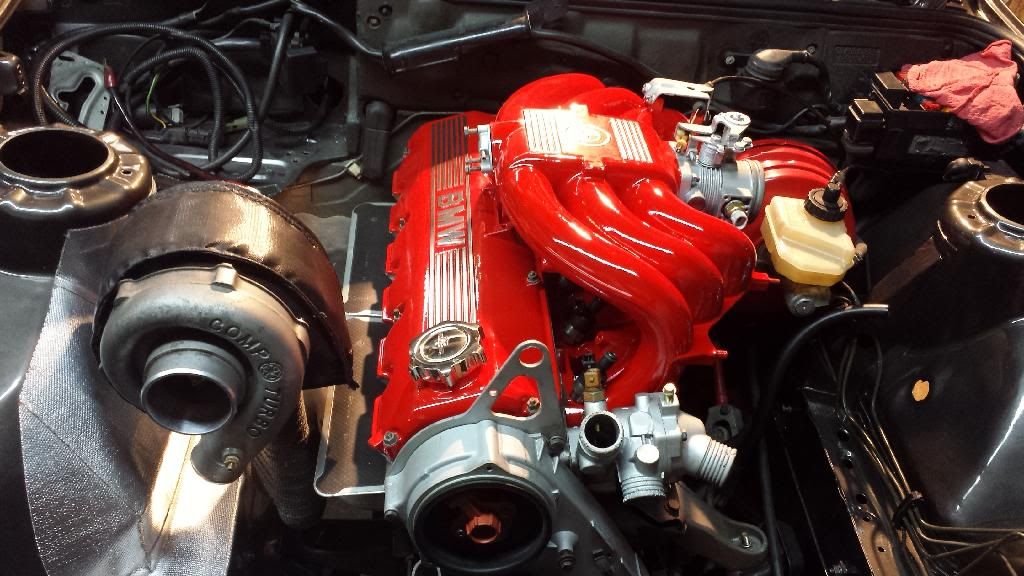

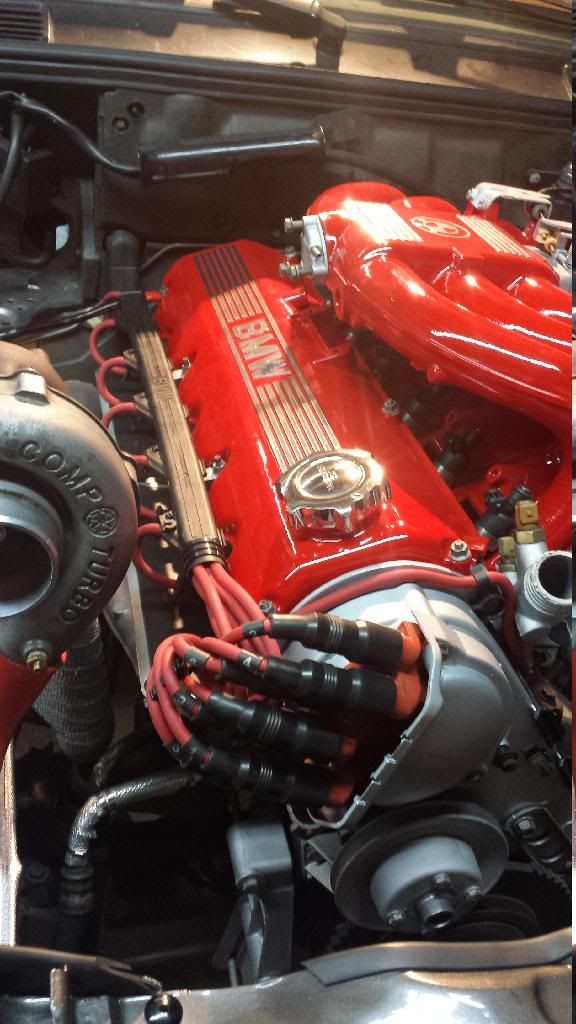

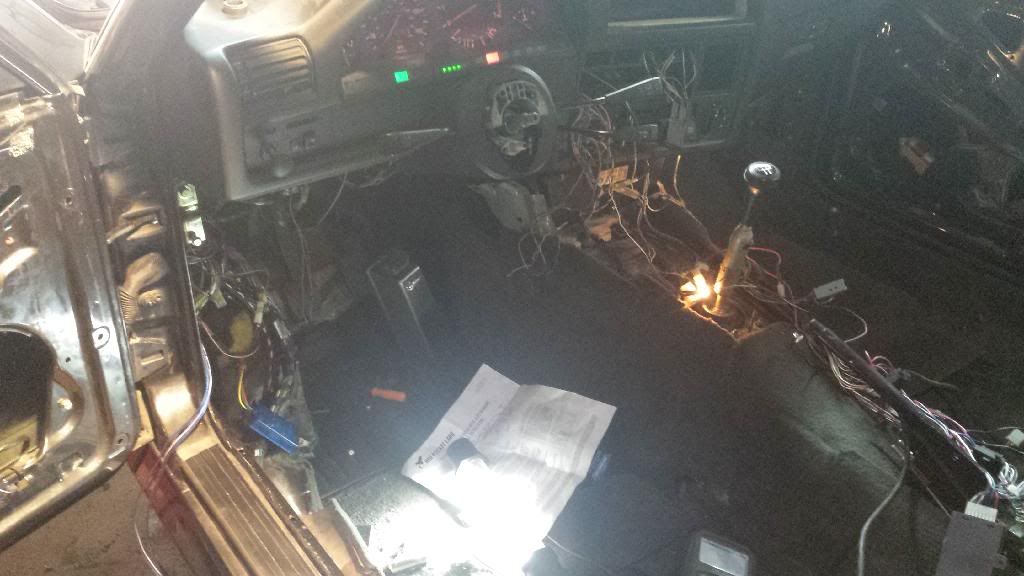

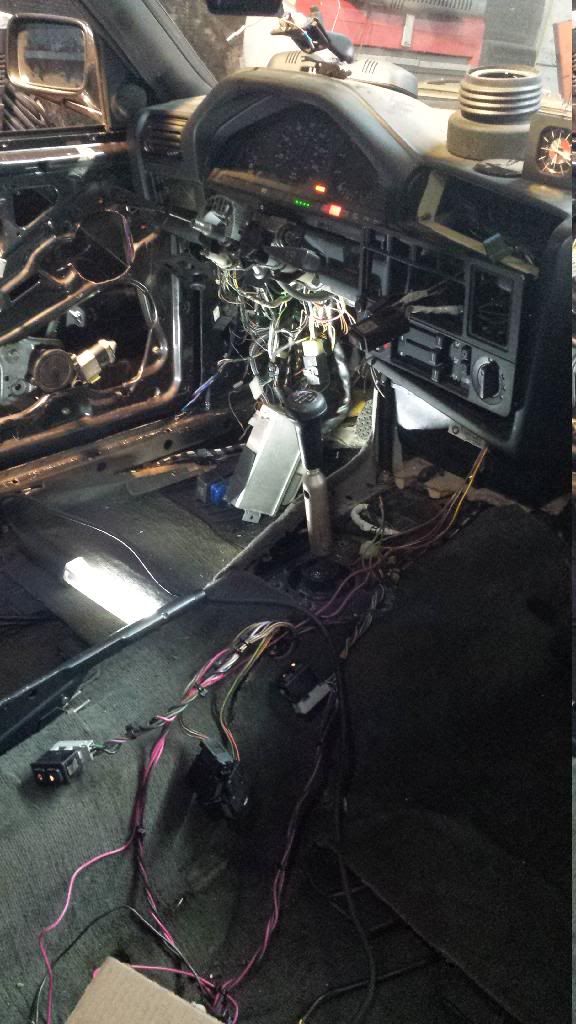

Got to the transfer case finally all cleaned and sealed.... and finished swapping the pedal clusters. At this moment all I have to do before reinstalling the engine is attach the clutch master cyl. Hard line back on. I'm going to swap the old ACC core for one that's not damaged. The old one had a leak. Anywho... pics!

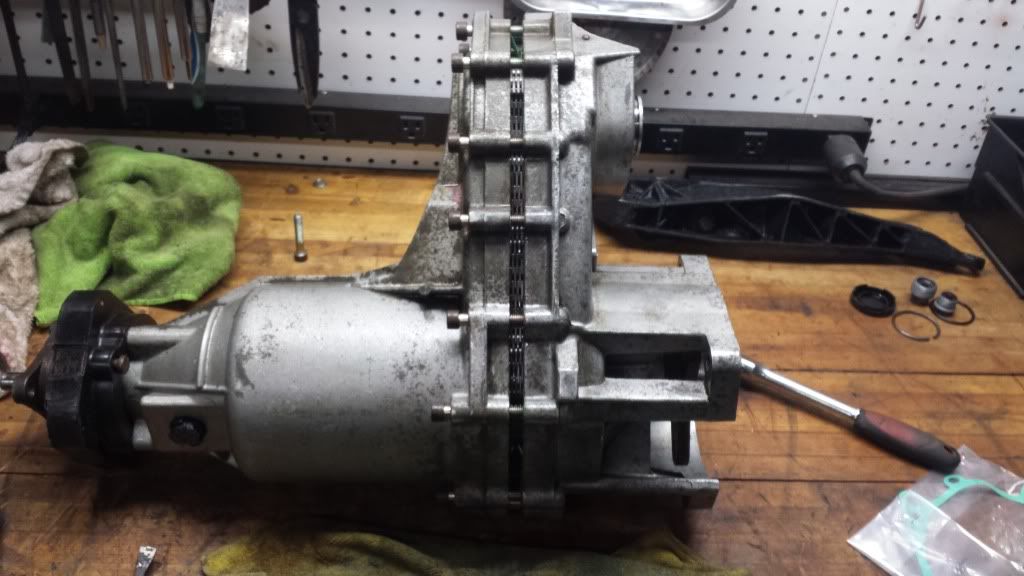

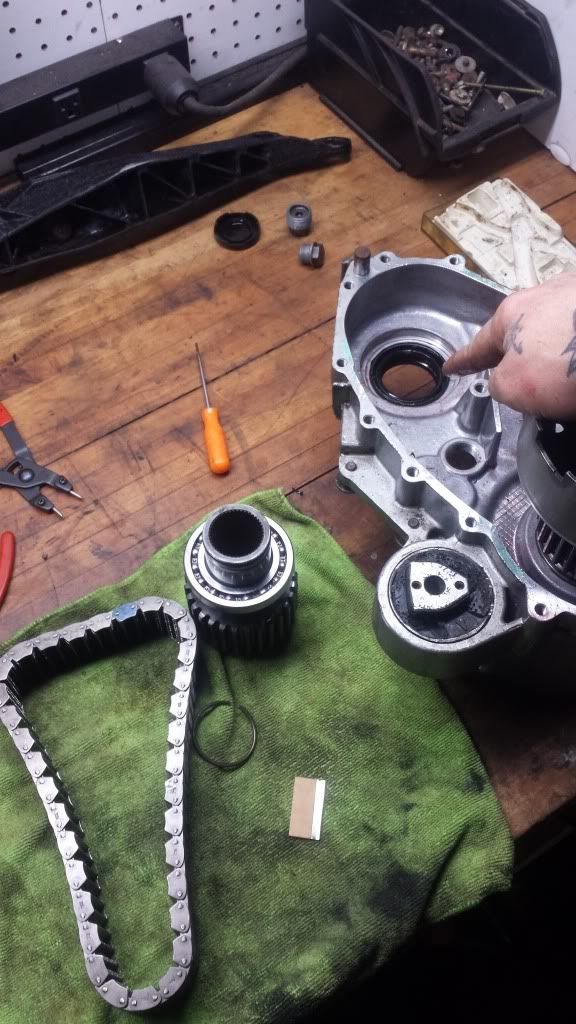

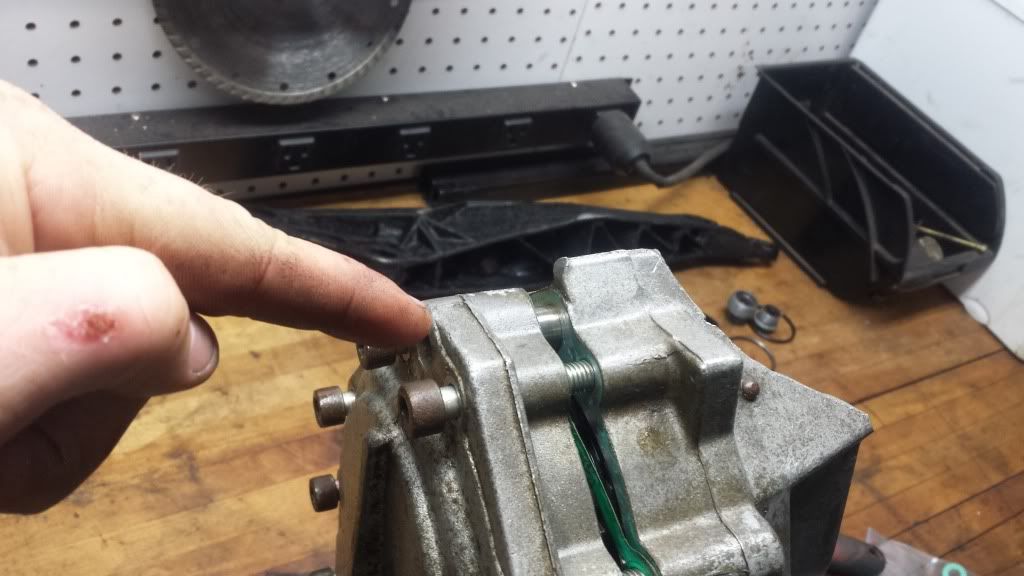

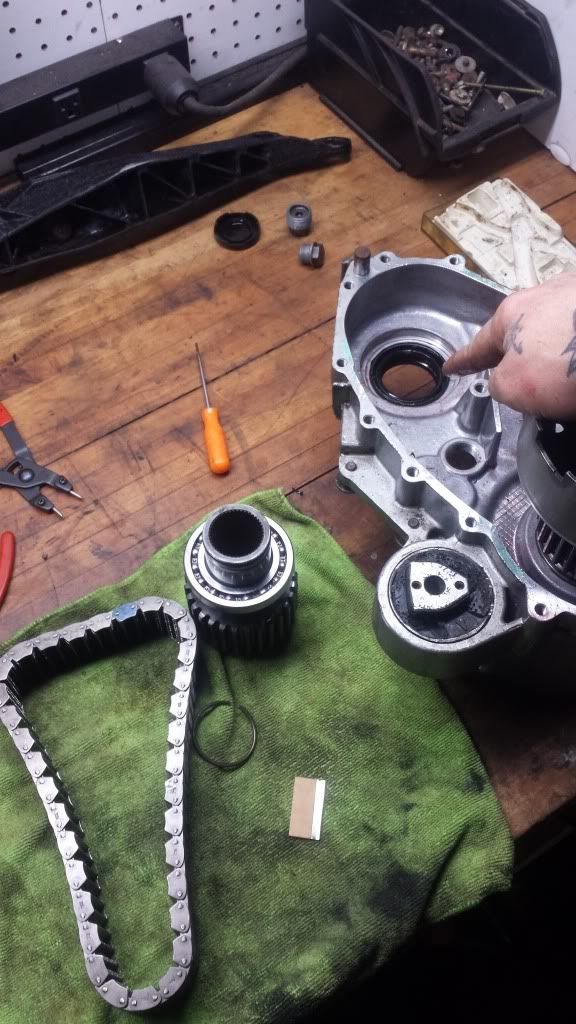

Got a main outer gasket, and this is the last seal I had to do after showing you how to do the other two.

Cracker the bolts all about 1/8th of an inch all the way around , hitting the bolts with a rubber hammer to separate.

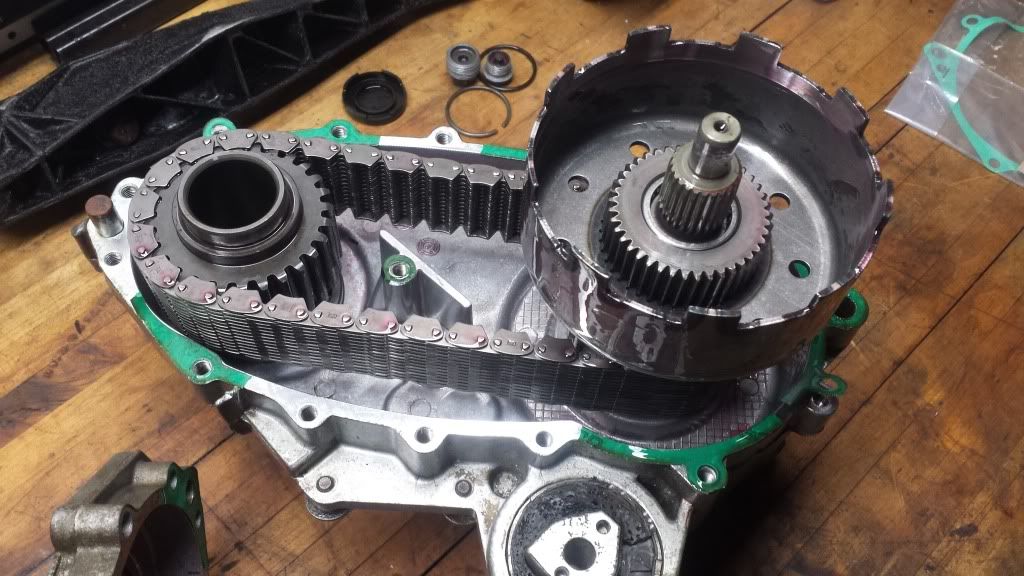

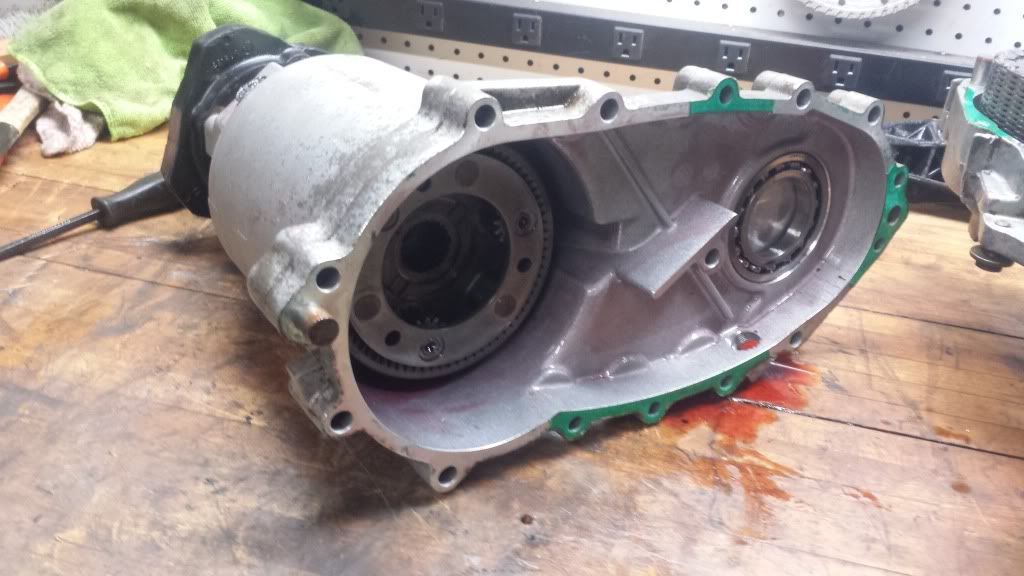

Once it's apart from the two aligning pins you should have your case exposed.

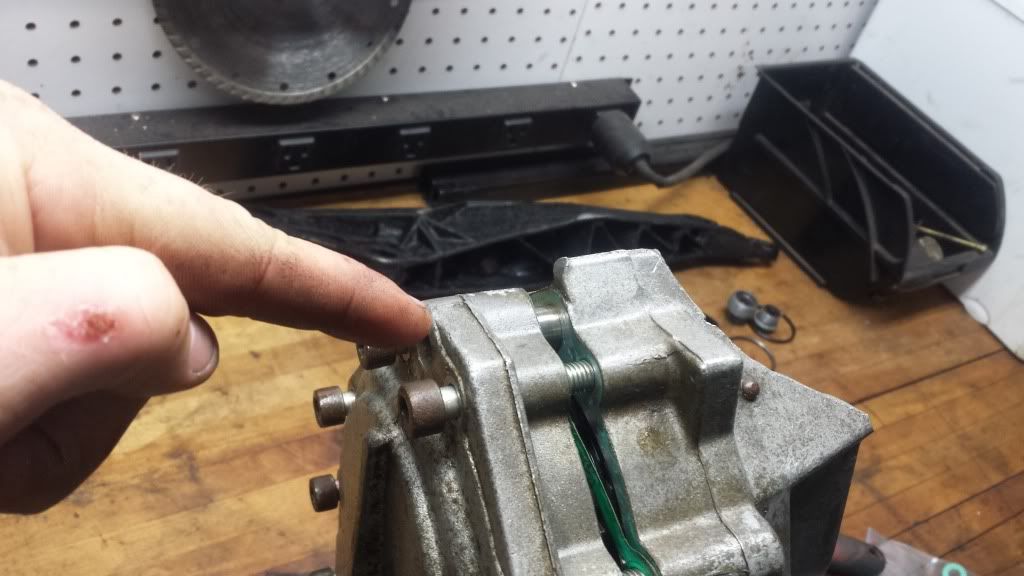

Pull up all the old green gasket and throw away. (Don't Foret about the middle hex nut gasket on install!!)

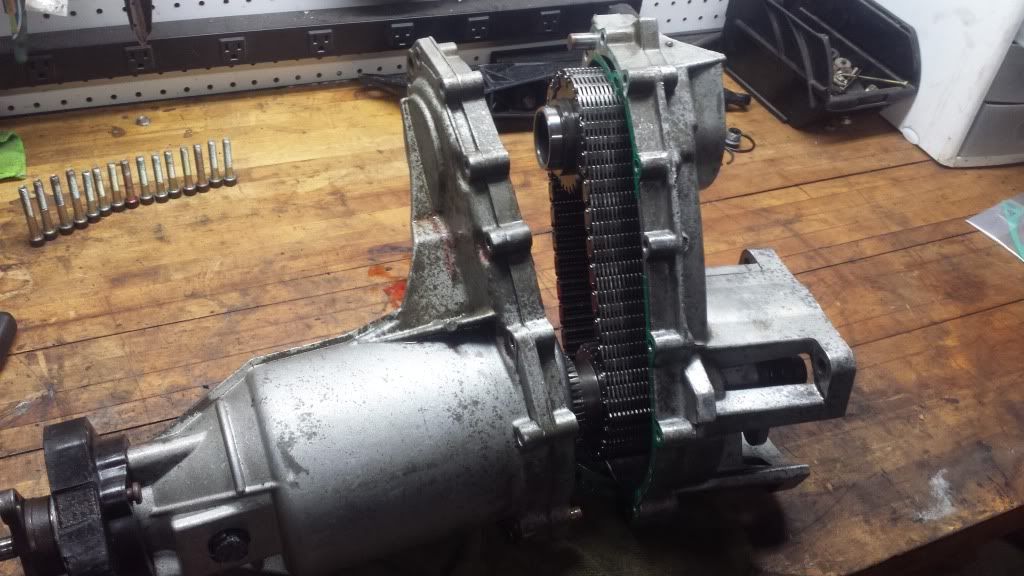

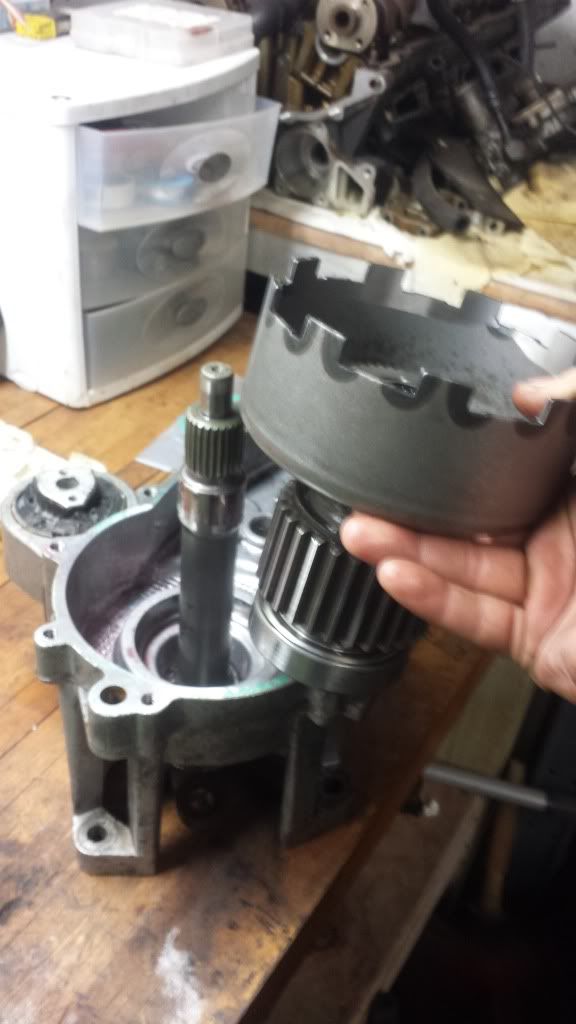

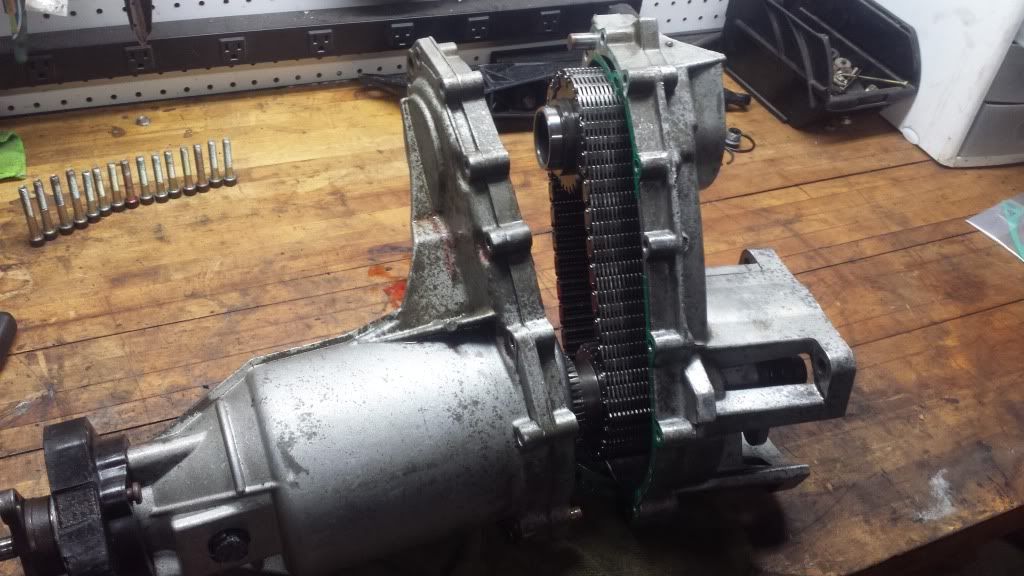

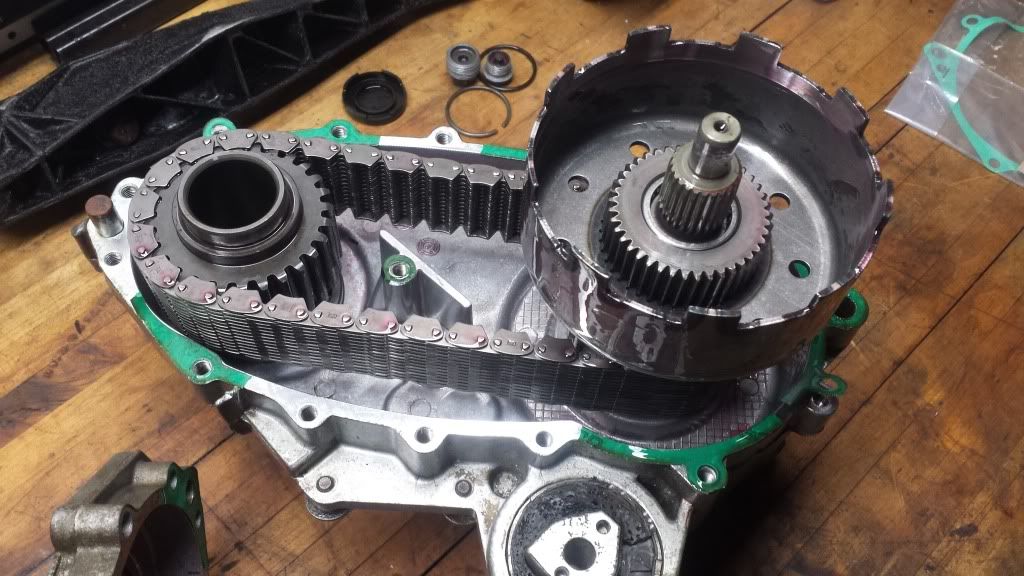

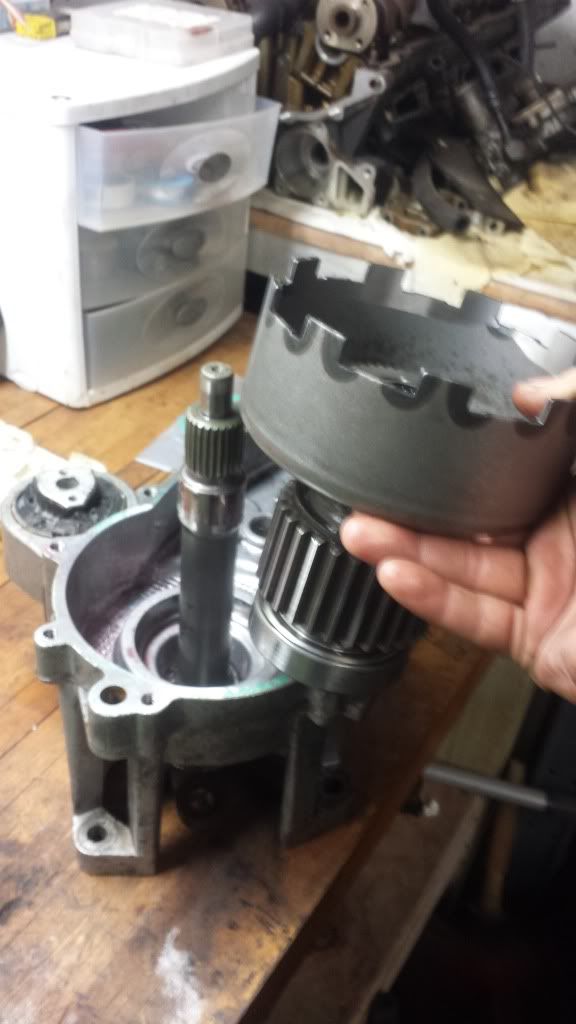

Remove this gear to get the chain off.

Then remove this assembly after moving the chain. This will expose the main shaft with a c clip. This shaft has more potential to vibrations, making it a common area for seal failure.

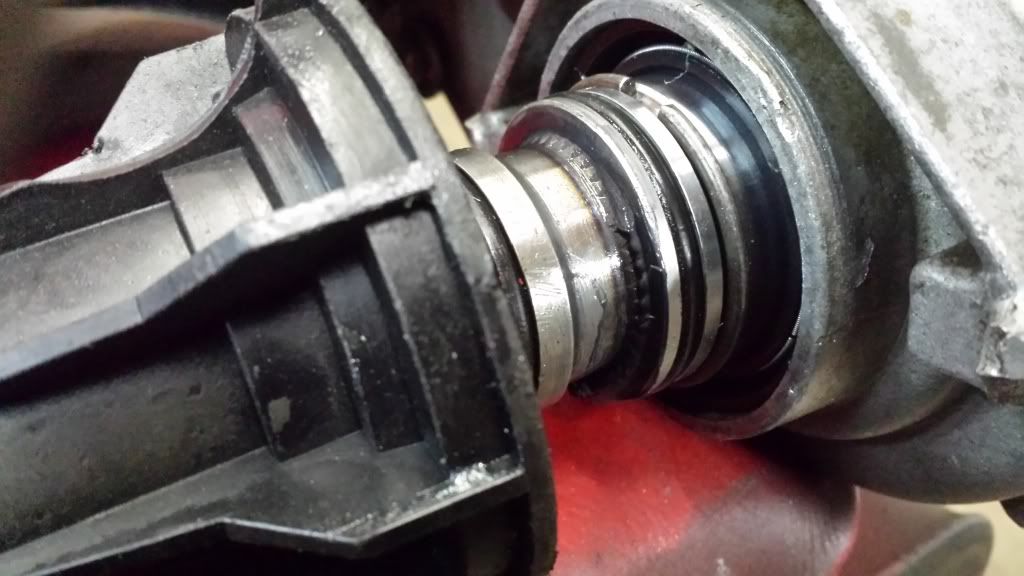

Got our seal ready. Pull out the old one any way you can, be I g careful not to score up the wall of the seal. I have a seal puller, but any pick or hook can snatch it out

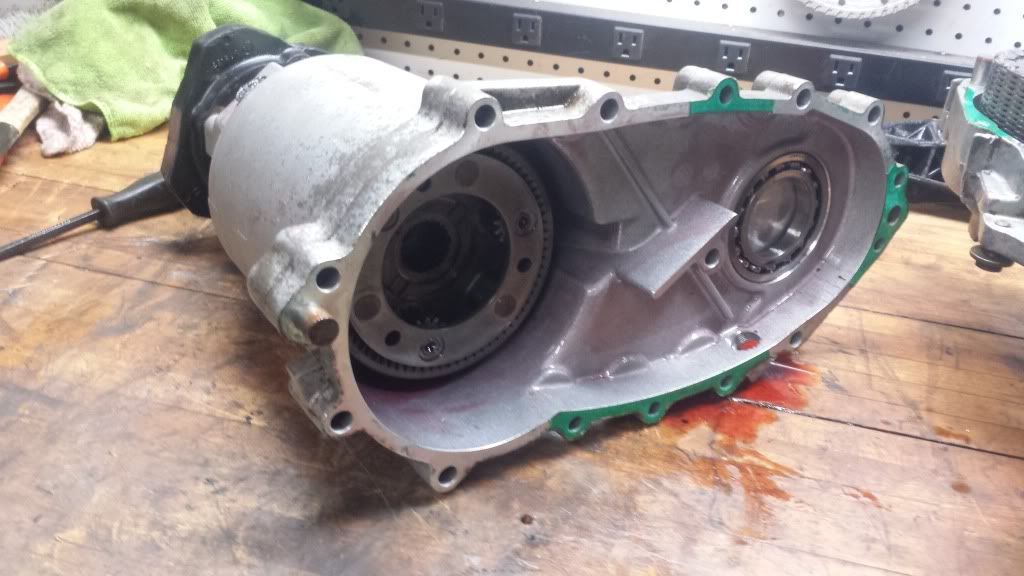

Clean every removable part and transfer case covers to remove lots of old debris! You'll be surprised how much you fin on your rag.

After installing the new seal, you can put the old seal in also, double stacking them to 1, reduce shaft play, and double your sealing efforts. Install the second seal backwards for later removal.

Reinstall shaft w/ c clip after doubling seals.

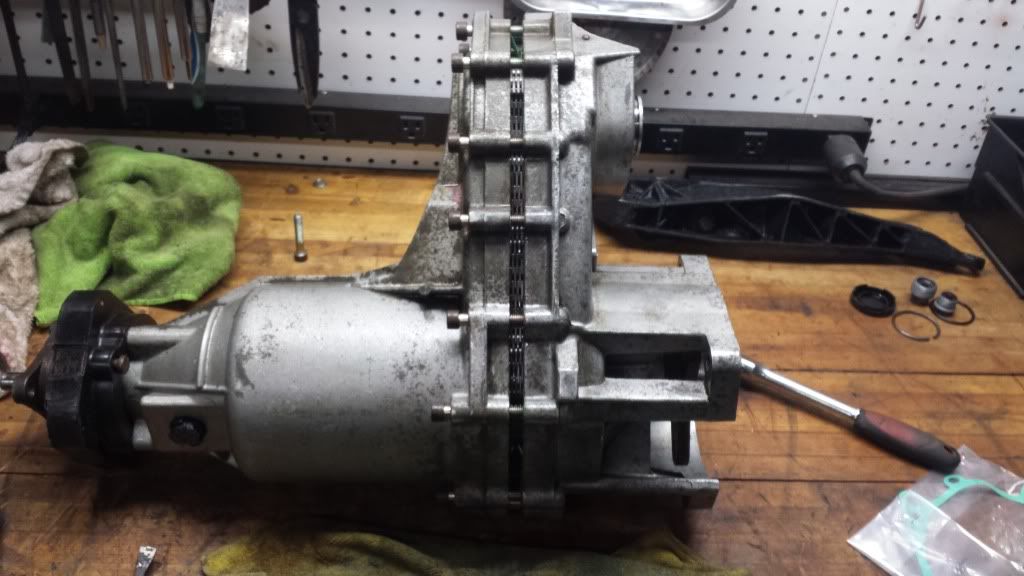

Install in opposite order from removal, scrape old gasket surface, and install new gasket. Don't forget the small single gasket for the center nut.

Tighten everything up in a cross like pattern so everything seats evenly.

All done! Ready to go back on the motor.

Some people would fill the transfer case with the fluid at this point, but I will be doing all my fluids at once while everything is installed further down the road. It's easier for me to log all at once, what type of oil is going Where, and the amounts they took considering every drivetrain unit has been completely dried and cleaned inside.

Got a main outer gasket, and this is the last seal I had to do after showing you how to do the other two.

Cracker the bolts all about 1/8th of an inch all the way around , hitting the bolts with a rubber hammer to separate.

Once it's apart from the two aligning pins you should have your case exposed.

Pull up all the old green gasket and throw away. (Don't Foret about the middle hex nut gasket on install!!)

Remove this gear to get the chain off.

Then remove this assembly after moving the chain. This will expose the main shaft with a c clip. This shaft has more potential to vibrations, making it a common area for seal failure.

Got our seal ready. Pull out the old one any way you can, be I g careful not to score up the wall of the seal. I have a seal puller, but any pick or hook can snatch it out

Clean every removable part and transfer case covers to remove lots of old debris! You'll be surprised how much you fin on your rag.

After installing the new seal, you can put the old seal in also, double stacking them to 1, reduce shaft play, and double your sealing efforts. Install the second seal backwards for later removal.

Reinstall shaft w/ c clip after doubling seals.

Install in opposite order from removal, scrape old gasket surface, and install new gasket. Don't forget the small single gasket for the center nut.

Tighten everything up in a cross like pattern so everything seats evenly.

All done! Ready to go back on the motor.

Some people would fill the transfer case with the fluid at this point, but I will be doing all my fluids at once while everything is installed further down the road. It's easier for me to log all at once, what type of oil is going Where, and the amounts they took considering every drivetrain unit has been completely dried and cleaned inside.

Comment