Ryan's 1974 M2

Collapse

X

-

So I lied... again. Still no start with the S14. I spent my last free days with a few non essential items that were just on my mind.

While the carpet was out, and to shave a little weight, I grabbed some dry ice and a scraper to remove the sound deadening material on the floor boards and trans tunnel.

Easy process, cost was about $12 in dry ice. Worked it over each section until the material started to creak. So far, just from sound deadening material the car is down 34lbs.

I was planning on tossing the 41 year old original carpet but upon closer inspection it didnt look too far gone. After hosing it down and scrubbing it with laundry detergent I was glad I saved it. Off to the hardware store for some fabric dye and here were the results. FWIW, the carpet originally was green-ish with some black in it and the floor mats were dark gray. I think it came out halfway decent. I used the same dye technique that I used on my E30, Rit dye to get the deeper fibers and then the aerosol gloss black dye to finish it off.

I also downloaded that cool app where you can play around and modify with your car. Hoping this rendering is about where the car ends up once its "done".

I have a parcel coming from the Netherlands with two items inside, will report back with photos once they arrive and get installed onto the back of the car. And no, a rear spoiler is not one of them ;D:crazy:Leave a comment:

-

I'll check them out. I need to grab a few more now that I am thinking about it.

I'm going to call you guys again soon over at IE and get my brake system ordered so I can take this thing for a test drive. I highly doubt Ill ever run wheels smaller than 15's, but I don't necessarily want to exclude the possibility in the future as of now. Thats keeping me from placing the order now :/ .Leave a comment:

-

I get this question a lot. And I wish I still did as it was recently rebuilt before the car went into storage by the PO and in nice shape. Unfortunately the power train is gone, I gave it away to a couple of local guys who came over to buy the original interior right after I began the tear down.Leave a comment:

-

+1 for OG BMW clamps, Wurth also makes a good replacement. If they aren't stainless they have a very nice coating, most of the time a quick wipe and they shine up like new. After a brand-new typical parts store "fuel injection clamp" recently bit into my new fuel line causing a leak I'm hesitant to run them anymore.Leave a comment:

-

They don't need to say bmw on them. There are several brands and they are superior in several ways.

They are narrower so require less tightening load for the same clamping force.

The edges are rolled up so they cut into the hose less.

The grooves the worm gear drives into are pressed into the band and can't slice the hose like slots in the american ones.

They also look better.

Ahh I see. I do see what your sayin about the edges being rolled. I guess I've never really thought about the difference. I just replace them when they go badLeave a comment:

-

They don't need to say bmw on them. There are several brands and they are superior in several ways.

They are narrower so require less tightening load for the same clamping force.

The edges are rolled up so they cut into the hose less.

The grooves the worm gear drives into are pressed into the band and can't slice the hose like slots in the american ones.

They also look better.Leave a comment:

-

BMW clamps, in my experience, have less of a tendency to strip. Myself, I prefer them in higher-pressure applications such as fuel injection lines. However, in scenarios such as a random cooling hose, I wouldn't be afraid to use an American clamp.Leave a comment:

-

Im not sure of the quality or clamping ability vs. the two but I grabbed some that were black so they blend in better and don't look so obtrusive.Leave a comment:

-

Ryan's 1974 M2

What makes European hose clamps so special? As far as I'm concerned a hose clamp is a hose clamp. You'd just be paying more for one with BMW stamped on it.

Good work man looking forward to seeing a start up vidLeave a comment:

-

Hah, I forgot to mention all zip ties and ugly hose clamps are temporary. As are some of the hoses! Already have the proper ones ordered.Leave a comment:

-

Nice work.

I hope you are going to replace those horrible american style hose clamps with proper european ones.Leave a comment:

-

This Xmas break was one of my last chances to put some work into the 2002. Since I'm a recent graduate, I had been using December to look for and secure a permanent position. On the 29th I was offered full time work between two dental offices giving me a total of 6 days/ week of work :D . With that in mind, and knowing the car is 2 hours away from my home in the Bay Area I worked around the clock over the break to finish up the last jobs before my opportunities to do so in the future become limited.

There were a few things that I needed to finalize on the engine. First, the coolant plumbing. Finding the hoses that will mate up between the S14, the 2002 components, e21 components, and the aftermarket bits. A few of the S14 hoses worked great, the hoses between the water pump and 2002 thermostat and the coolant crossover pipe to the upper radiator were a different story. I started my hunt at AutoZone in the back staring up at the wall of random hoses. After 30 minutes I found 3 that had the bends in the proper diameter that would work out. Look closely and you can see the Gates P/N's.

I copied Marshall's M2 build and used standard 16mm hose to connect the heater core line to the coolant tube under the plenum. The factory 2002 heater core inlet tube works fine as is to connect to the back of the head.

The biggest obstacles are routing the tubing in the tight space left between the radiator and the front of the engine keeping it safely traveling up and around the main crank pulley. Finding a hose with some tighter 90* bends followed by a straight section makes it much easier. Also, on my late model 2002 I found it much easier to use the 2002 thermostat versus the e30 M3 equivalent. The slimmer 2002 housing doesn't rub on the passenger bumper shock mount and has the proper angels to mate up to their respective fittings. One thing I did do to the 2002 thermostat was I sectioned away the 45* bend on the lower tube (the fitting that will mate up with the lower radiator). By sectioning this bend off, you end up with a straight section on the bottom of the thermostat housing, leaving you with a 3 inch straight shot gap to make the connection.

The vacuum system was about the same as the coolant system. I utilized almost all OEM S14 hoses aside from modifying two OEM hoses to integrate to the 2002. First was the hose between the plenum and the oil separator, it had to be cut in half and added to a copper fitting with a bend in it to clear the oil filter hosing/ oil cooler lines and still mate up. The other was the line from the valve cover also to the oil cooler. It was 4 inches short due to the oil separator being shifted over to make room for the 2002 driver side engine mount. I added a T fitting here and a 1 way valve to give vacuum to the booster and ran the other side of the T back to the oil separator.

Next up, finishing the oil system. I needed to incorporate the VDO senders for oil temp and oil pressure to my VDO gauges. I left the new OEM factory oil pressure sender for now as I planned on wiring in an idiot light to work off of it. Where the E30 M3 S14 once had a factory oil temp sender, I threaded in an M12 X 1.5 to 3/8 standard fitting. I then could build up a little apparatus to house both VDO senders, and position them where they can be accessed and where they are still out of direct view. In the pic below the oil temp sender isn't installed, the oil pressure sender sits at 45* at the very end of the apparatus about 3 inches from the oil filter housing.

Scope creep again. Even though I had the factory headlamps and turn signals installed, the allure to install the new Euro turns and Hella Super Euro headlamps was too great. MoBrighta sent along lens covers to go over the headlamps and keep them crack resistant. Installing these was breeze, just used some H20 and OH- mixed 3:1 and a heat gun. The covering was thick, and I am very pleased how it turned out as they're completely invisible.

P/N for the headlamps:

I started first by installing the head lamp bulbs and the city light bulbs.

Next up, made a station for the laminate application.

One done, can you tell which one?

And both assemblies complete. I resprayed the bucket rings and cleaned up the buckets. Bulbs in, protective covers on both the bulb socket and the glass.

Installed:

I also spent a night or two improving upon previous projects. For instance, in the throttle cable assembly there was added resistance when depressing the gas pedal. Most of this is from the spring that resists the depression of the gas pedal and returns it back towards the driver, however some was from the way the brackets are designed (if following the Aardvark swap guide). Here is my solution:

Its hard to see whats going on if youve never made these brackets. What happens is when the driver depresses the gas pedal, an arm on the other side of the fire wall moves throughout space in the same plane as the arc the gas pedal travels through as you push it down to accelerate. A bracket is created to attach to the end of this arm and this bracket acts as the anchor point for the throttle cable. Directly above this arm/ bracket assembly, another fabricated bracket mounts firmly to the pedal box assembly to be the connection point for the throttle cable outer sheath (picture any standard throttle cable design with the outer sheath and the inner steel cable). The problem is seen in the tension that can develop as the arm/ bracket pull the throttle cable. Since this arm must swing in an arc to pull the cable, it moves in two planes and causes a sort of pinch point to occur. Ideally, the throttle arm would move in one direction directly away from the bracket that retains the outer sheath of the cable to reduce all tension in the system. To mimic this I made the following modifications to the original bracket design.

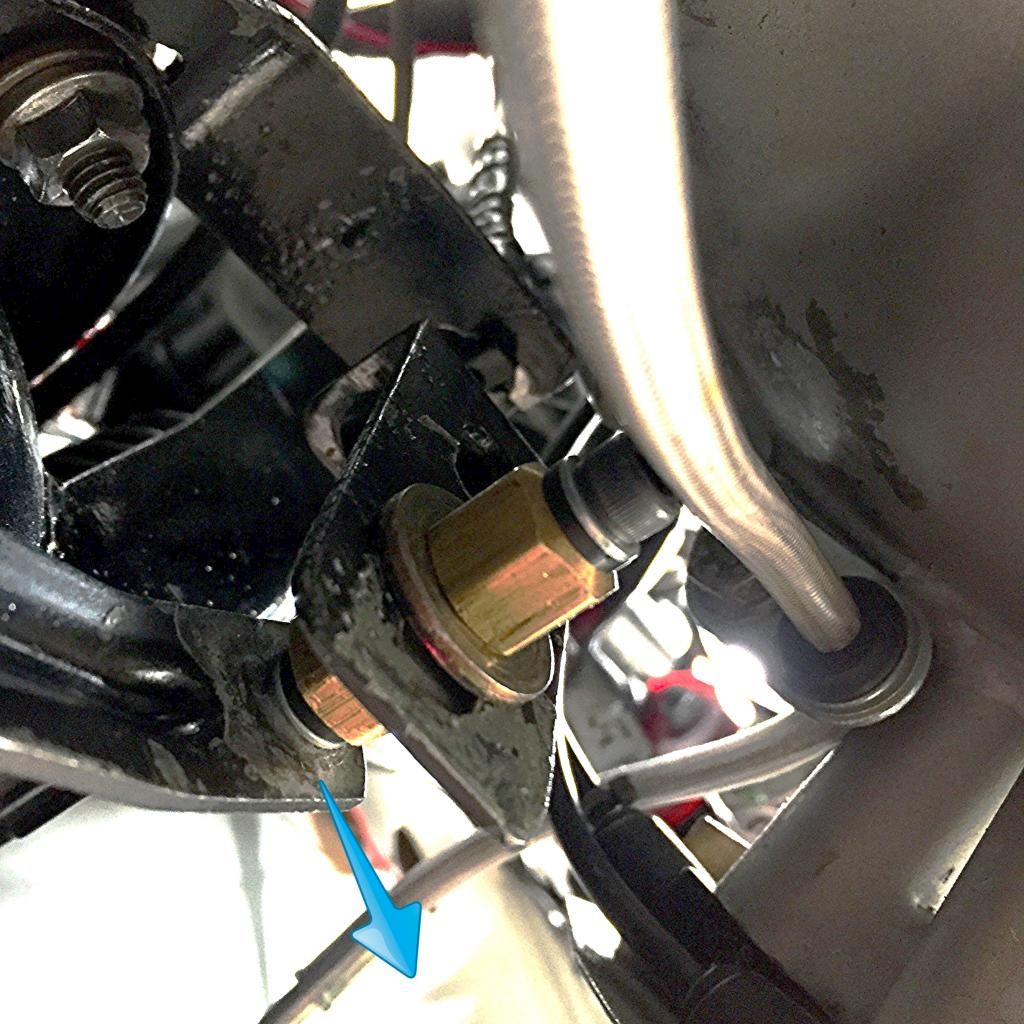

Here are the brackets as they were before modification. The gold nut is attaching the throttle arm to the first bracket mentioned above^. You'll notice the second bracket above these, it has the ~135* bend in it.

My solution was to add a pivot point where the throttle arm and the first bracket meet so that the throttle cable is always being pulled directly away from the mount that secures the outer throttle cable to the pedal box. This greatly reduced the tension that was in the system before the mod. The blue arrow represents the direction of travel of the throttle arm as the gas pedal is depressed.

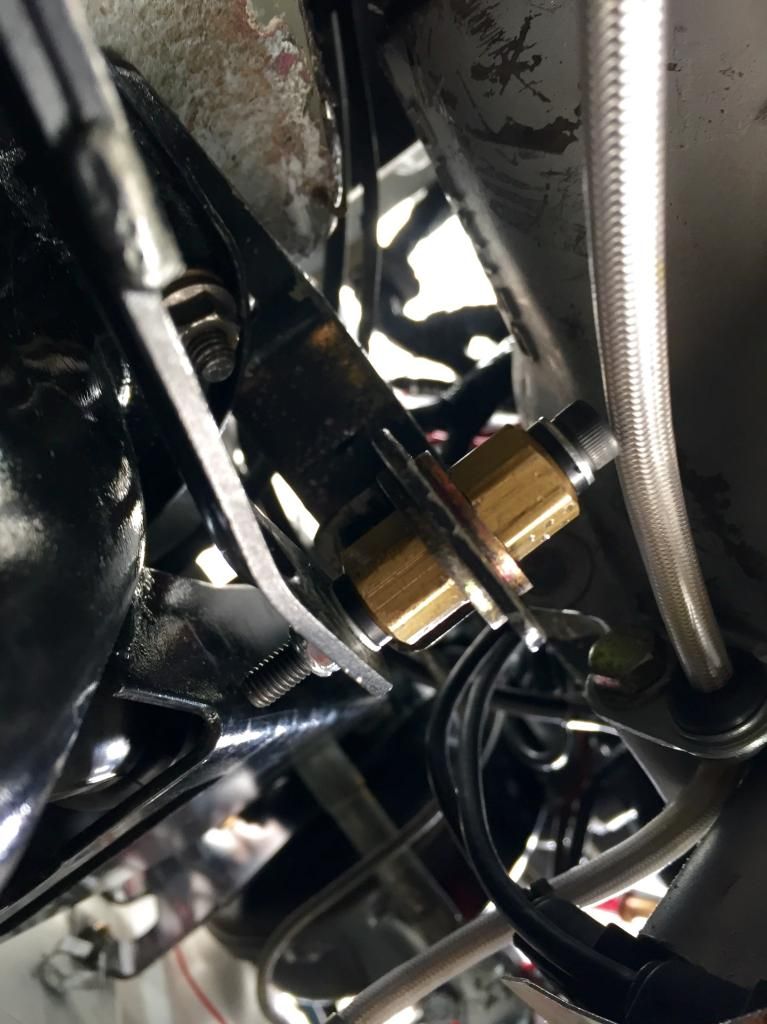

Here is a better shot of the final product. Basically, I used a few brass NPT fittings to make this. The brass fittings pass through the slightly enlarged hole in the original bracket design plan. On either end of the fitting system are male threads that allow end caps to tighten down and hold everything together. I grabbed the end caps and drilled holes through them the same diameter as the center hollow fitting. Nylon bushing form ACE were pushed into either end and an M5 bolt traveled through these bushings and connects back up with the throttle arm. A nylon lock nut holds it all together and allows rotation to occur still as the nut isn't locked down 100%. I set the drag just so that rotation can occur, but so that there is no slop being produced.

And finally, that moment when you realize you're ready to add fluids and turn the key. Enter tacky IG pic.

Fun stuff ahead ;DLeave a comment:

Leave a comment: