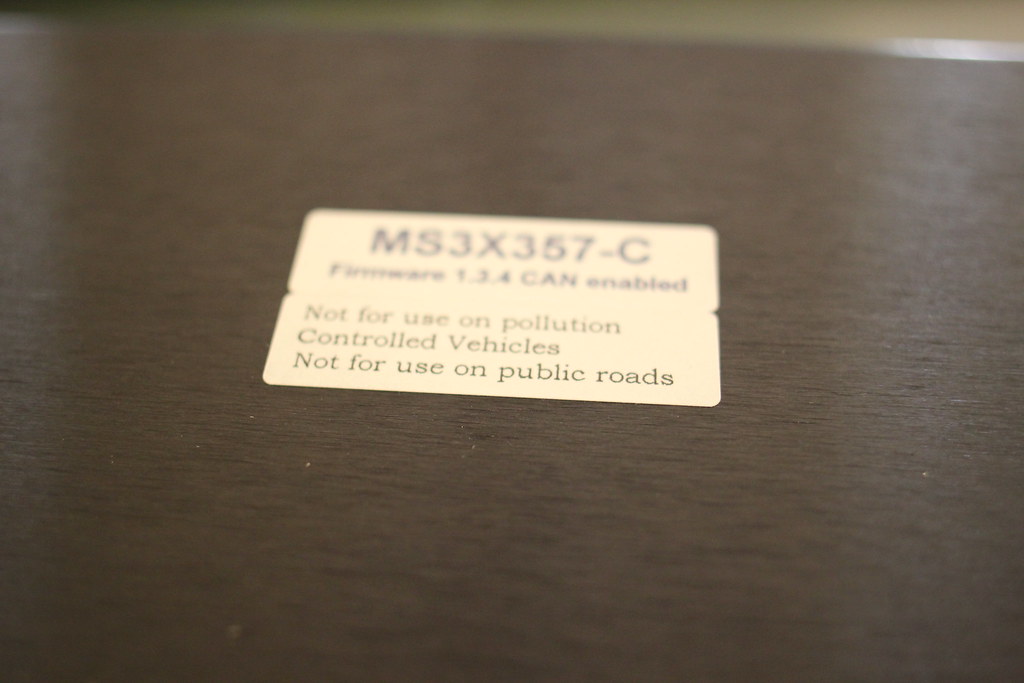

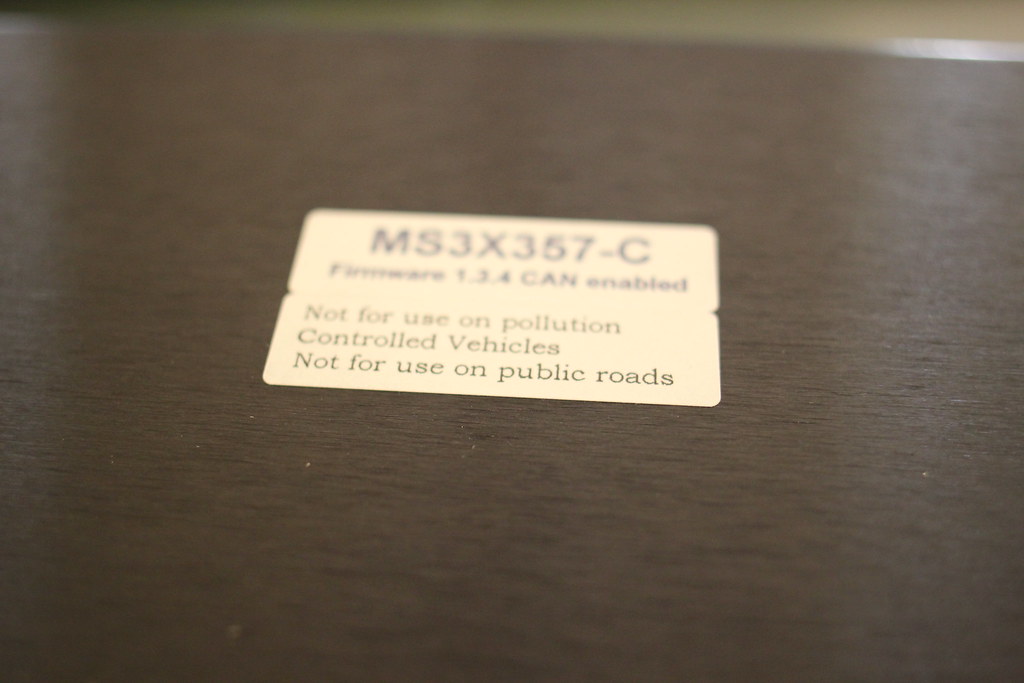

I finally took a dive off the deep end and pulled the trigger on MegaSquirt3x. I'll document my process as best as I can. This is going to be a huge learning experience for me so go easy.

I have a built, turbo S52. I'm currently doing a head gasket on it due to the MLS gasket not holding up to my terrible tune.

Link to build thread: http://www.r3vlimited.com/board/showthread.php?t=303817

And go:

Where are the directions for this thing??!

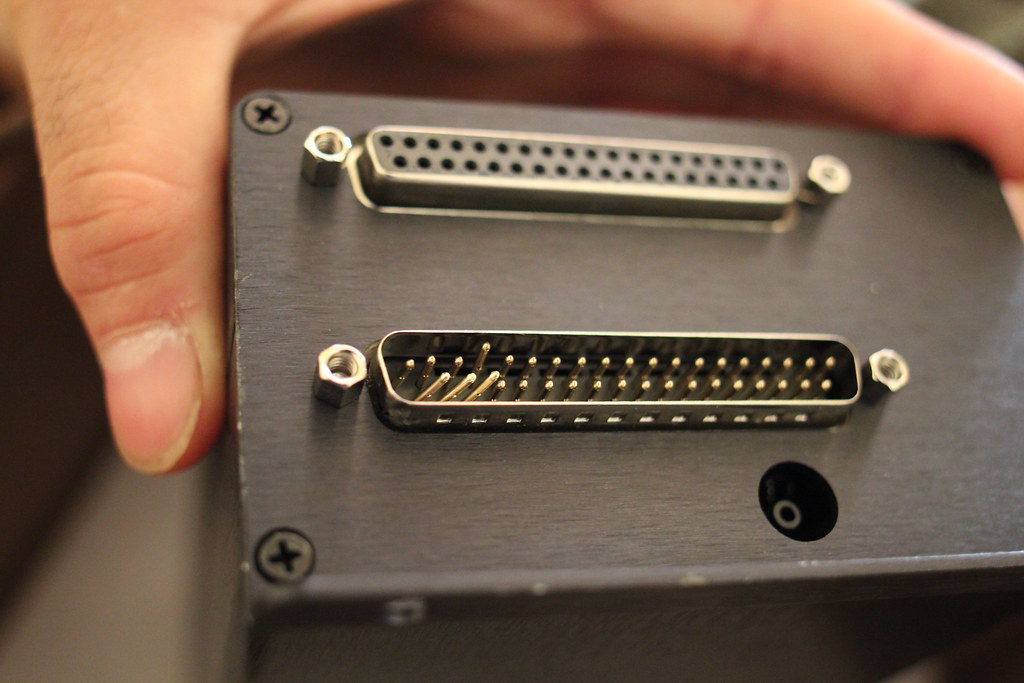

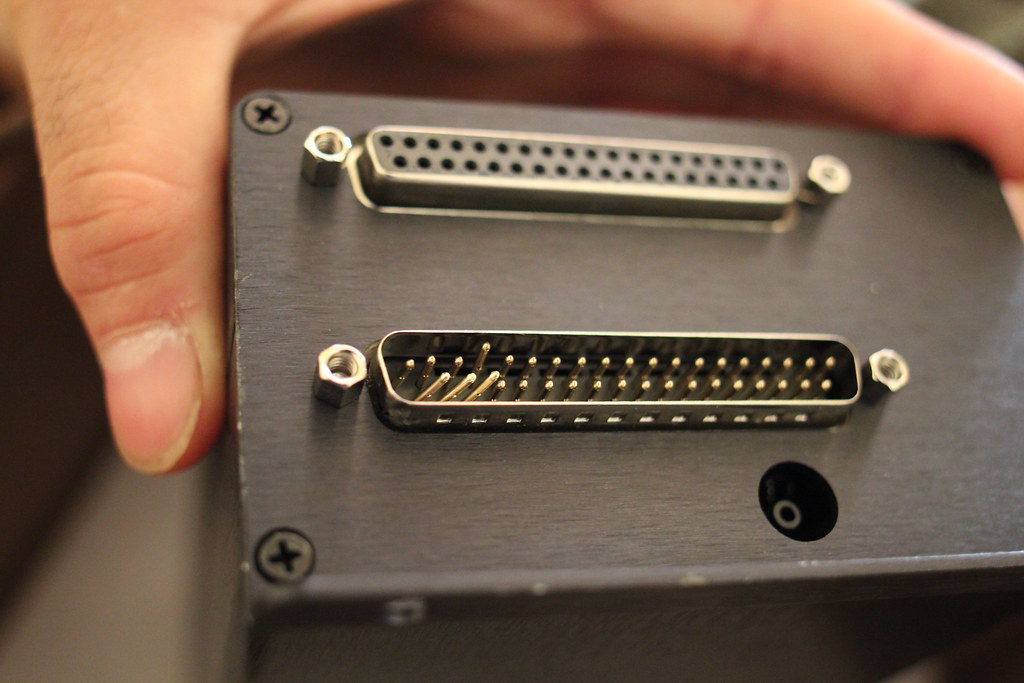

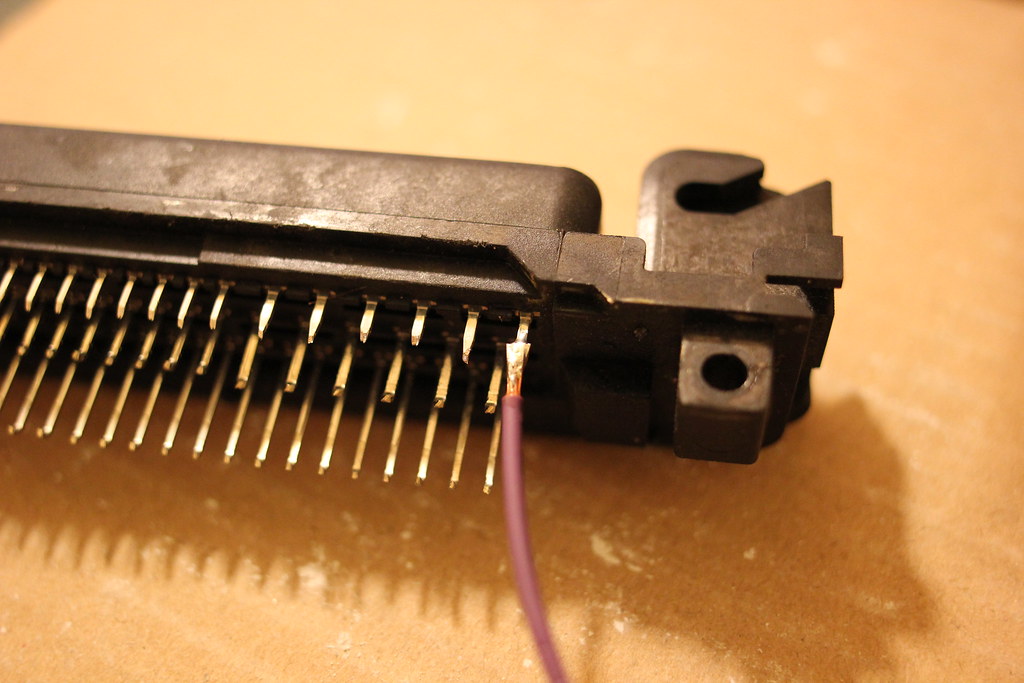

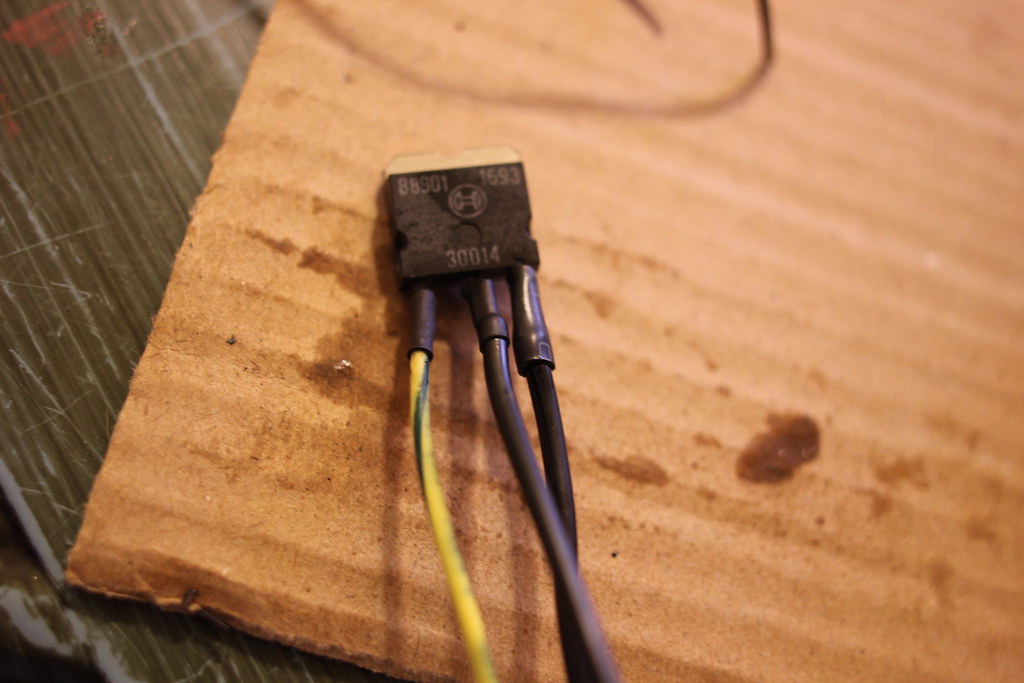

If you look at the first pic you can see where the connector was digging into the MS3x.

I have a built, turbo S52. I'm currently doing a head gasket on it due to the MLS gasket not holding up to my terrible tune.

Link to build thread: http://www.r3vlimited.com/board/showthread.php?t=303817

And go:

Where are the directions for this thing??!

If you look at the first pic you can see where the connector was digging into the MS3x.

Comment