nice, looks good so far, cant wait to see what u do with it! :)

★★★★George Graves★★★★ Project Blog for e30 Gizmos and Gadgets - 2025 UPDATE

Collapse

X

-

I will own a 3d printer someday.

I'm curious to see the electronic hardware/software required. I can easily build a 3-axis frame from scratch, but making it work with a servo controller and micro-controller is where I start to struggle. I could work through it, but I'd have to learn a lot. Something plug and play would be nice.Comment

-

Comment

-

-

this is sahweet George, very interested in this. might motivate me to build one myself.Comment

-

since things are printed in layers, I wonder what's the structural integrity of an object. will it be as strong as casting and object?Comment

-

The reprap project, is a pretty mature. The electronics are 90% plug-and-play. The software side is were a lot of the magic happens - that will be the biggest stumbling block for most people. Building the printer is a breeze. If you can click on ebay links you can build a printer. Unfortunately, the software side of things has a long way to go till it's "click print and you're done"....I'm curious to see the electronic hardware/software required. I can easily build a 3-axis frame from scratch, but making it work with a servo controller and micro-controller is where I start to struggle. I could work through it, but I'd have to learn a lot. Something plug and play would be nice.

All the 3d printers on the market use steppers, not servos. There is no position feedback other than a home and (optional) limit switches to give the machine a point of reference before it starts printing. Since there is no load on the print head, this works fine.

Yes, there are lots of people using a 3d printer to make jewelry. Either making a mold for the wax or bypassing the wax process, and doing "lost PLA" casting. This guy has a really long video showing how he cast an aluminum block for his CNC machine using "lost PLA" casting. (not sure if it would work on something small) Her is the short version.

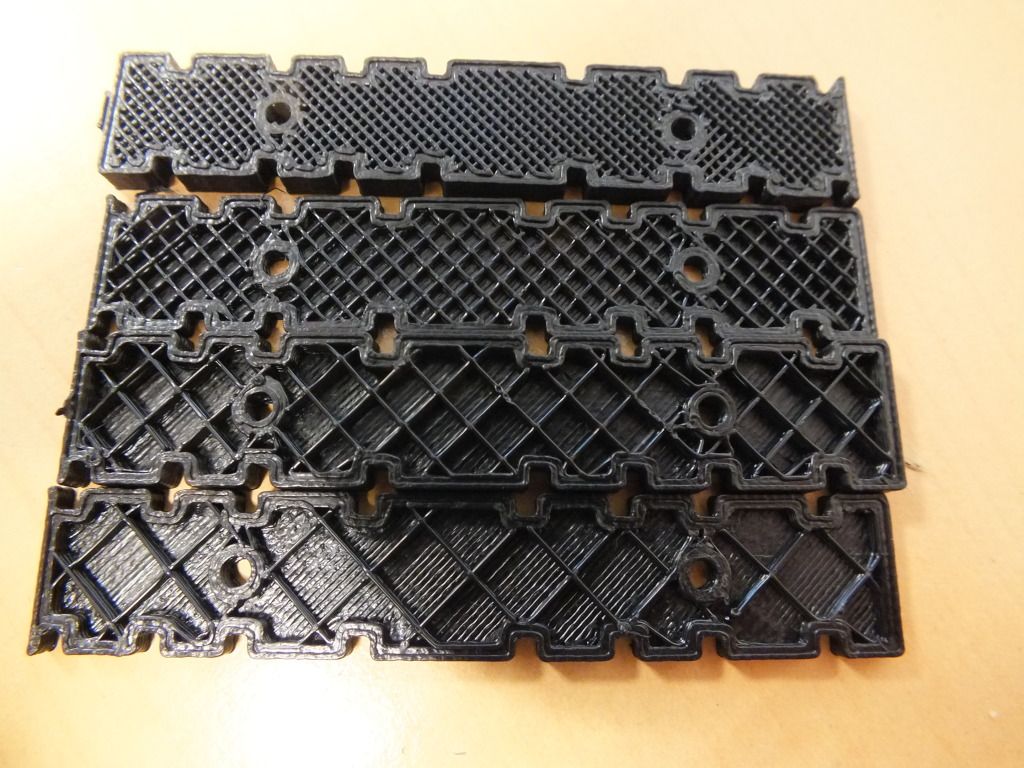

There's a lot of debate about this. It's kinda hard to make a apples-to-apples comparison. There are so many different types of plastic, and different ways to 3d print. For example, when you're 3d printing an object - say a cube - you don't have to have it be a solid piece. You can control the in-fill of the object. So, you can have the infill of it be honeycomb, or a grid. That allows for some insane strength to weight ratios. Something that is imposable with injection molding. So a lot of it comes down to the skill of the designer.

But 3D printed parts can be stronger then cast parts for sure.

skip to one min mark. Cast parts are yellow. Printed parts are the pink ones.

Last edited by george graves; 06-06-2013, 03:37 PM.Originally posted by Matt-Bhey does anyone know anyone who gets upset and makes electronics?Comment

-

-

Electronics arrive from China a few days after ordering (you gotta love FedEx)....

I ended up going with a kit. Again, you save a lot of shipping costs when you get everything together.

Here is what I ordered:

Ramps 1.4 ULTIMATE KIT+Smart LCD controller+3 Endstop+MK2+ 1 wiring set

Ebay USER ID: reprapdiscount

$189 (the accepted a "best offer" of $170) free FexEx 2 day.

1x MK2A Heat Bed (latest version):

- 1 x MK2A PCB with 1K resistor and 2 red led soldered

- 1 x 100K ohm EPCOS thermistors

3 x mechanical endstops

3 x hall endstops + 6 magnets

1x Smard LCD Controller:

- 1 x smart LCD Controller

- 1 x smart adaptor

- 1 x cable 50 cm

- 1 x cable 100 cm

- 1 x 4GB SD card (genuine Sandisk) exclusive to our auctions, no one offer this option

1x RAMPS Ultimate Kit

- 1 x ramps 1.4

- 5 x A4988 stepper driver

- 5 x heat sink

- 5 x conductive sticker (aluminum)

- 1 x Mega2560 board rev.3 (100% Arduino-compatible)

- 1 x SD Ramps

Free bonus included in this package:

- 2 x epcos 100K thermistors

- 1 x ceramic screwdriver

- 1 x 40x40mm fan

- 3 x GT2 pulleys, 9 screw, 1 alen key

1x Basic Wiring kits contain:

- 5 x 2 pin cables

- 8 x 3 pin cables

- 7 x 4 pin cables

Costs so far. $477.96 w/ $24.5 shipping - TOTAL: 502.46

It came very nicely packaged.

The kits includes goth mechanical and hall effect end stops. I'm not too keen on the hall effect end stops. But I might give them a try.

This is the timing belt used for the X and Y axis motion. It's really high quality. This is GT2 belt. Much better then what most 3d printers have been using.

Grub screws

The is the microcontroller, and stepper motor drivers. It also have headers for all the sensors, and such. It's based on a Mega 2560. Everything is modular so that if you burn something out - you can replace it. Also - this kit is nice, they give you a extra driver board, and some extras.

Quality is great - can't complain about anything.

A handy wiring kit (that I'm sure I'll modify) a SD card reader, an extra fan, and even a SD card.

Heated bed platform. It's kinda funny. It's just one big PCB with traces that zig-zag back and forth all over the board. You pass a current through it, and it heats up. A temperature sensor is mounted to the underside of the board to measure the temperature and send that data to the microcontroller

I still need to order a few more things. Mainly stepper motors. I've been putting that off - still shopping around on those.

A few odds and ends are coming in this week. The part that drives the plastic filament into the heated nozzle (hobbed bolt) - and some springs to level the heated bed.

Hopefully I'll be printing in a week or two.Last edited by george graves; 06-11-2013, 11:34 PM.Originally posted by Matt-Bhey does anyone know anyone who gets upset and makes electronics?Comment

-

-

This opens up a world of options for all those fiddly, expensive-to-replace plastic parts that make up so much of 1980s cars - plastic tabs and cogs inside larger mechanisms, sliders, etc.

Nice work, George. :)

(Mega late to this party, so excuse me if the cheerleader is already pregnant.)Pork Hunt Motorsport

eBay is like the summit racing catalog for today's special Olympics crowdComment

-

Sorry - no. I've had to switch focus on work that pays the bills. So it took a back burner.

A few 3d printer set backs. The hobbed bolt I ordered wasn't cut correctly(actually I spec'ed it wrong - my bad). I can't source m4 hardware locally like I expected to. And I *still* need to pick out some stepper motors(I'm quite picky in what I buy, if you haven't noticed)

On top of that I'm about to release a new product....so I've been "stress" testing it in my free time.Last edited by george graves; 06-25-2013, 06:26 AM.Originally posted by Matt-Bhey does anyone know anyone who gets upset and makes electronics?Comment

Comment