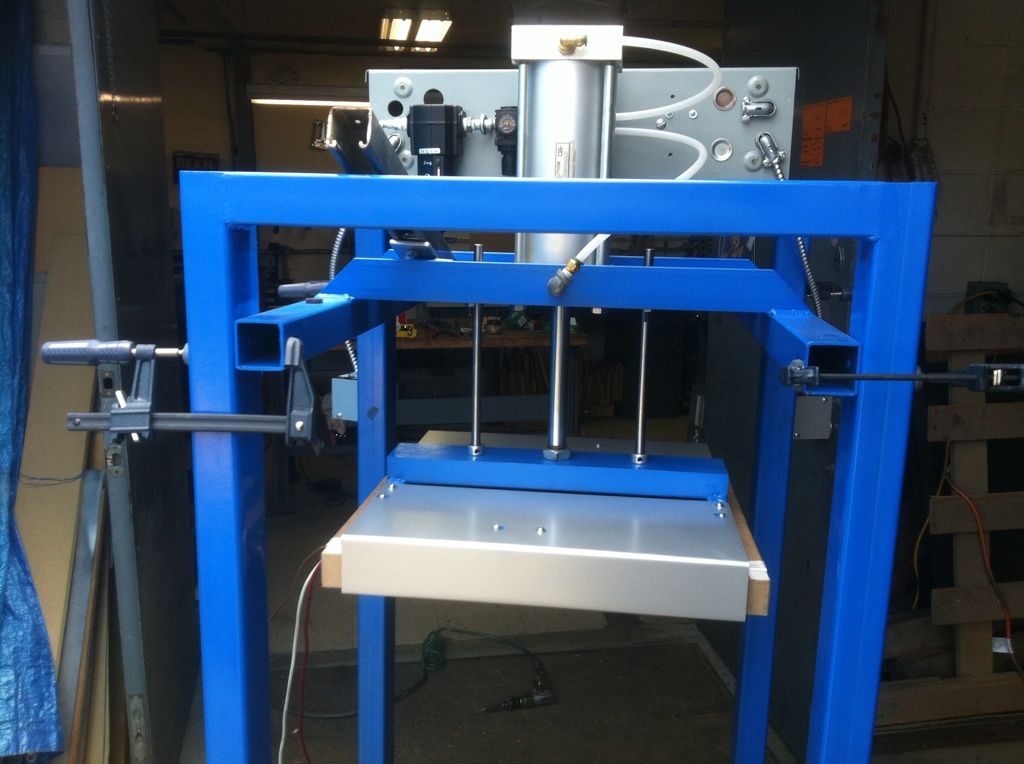

Just thought I'd share. I enjoy seeing everyone else's projects on here so here's my most recent. It's not quite done yet. It's a pneumatic heat press. It will have a "dash" with controls for adjusting temp/time/pressure/etc.

I'm using recycled metal from a huge horizontal band saw. I'll let the pics do the talking.

HF casters... ;)

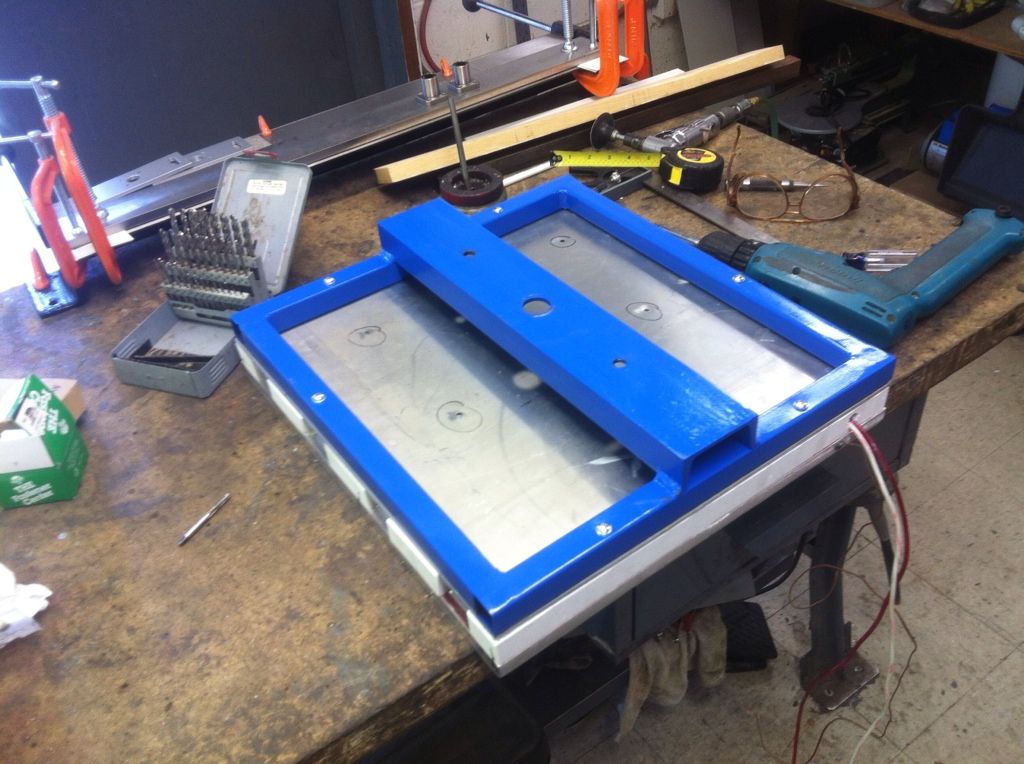

This is the frame for the bottom. An alu plate will be bolted on and leveled out. This will sit in the middle of the whole frame and be secured to the sides of the frame via bolts.

This is the piece that will hold the aluminum heater plate and push it down.

Here's the heating plate with that piece attached

Starting to take shape

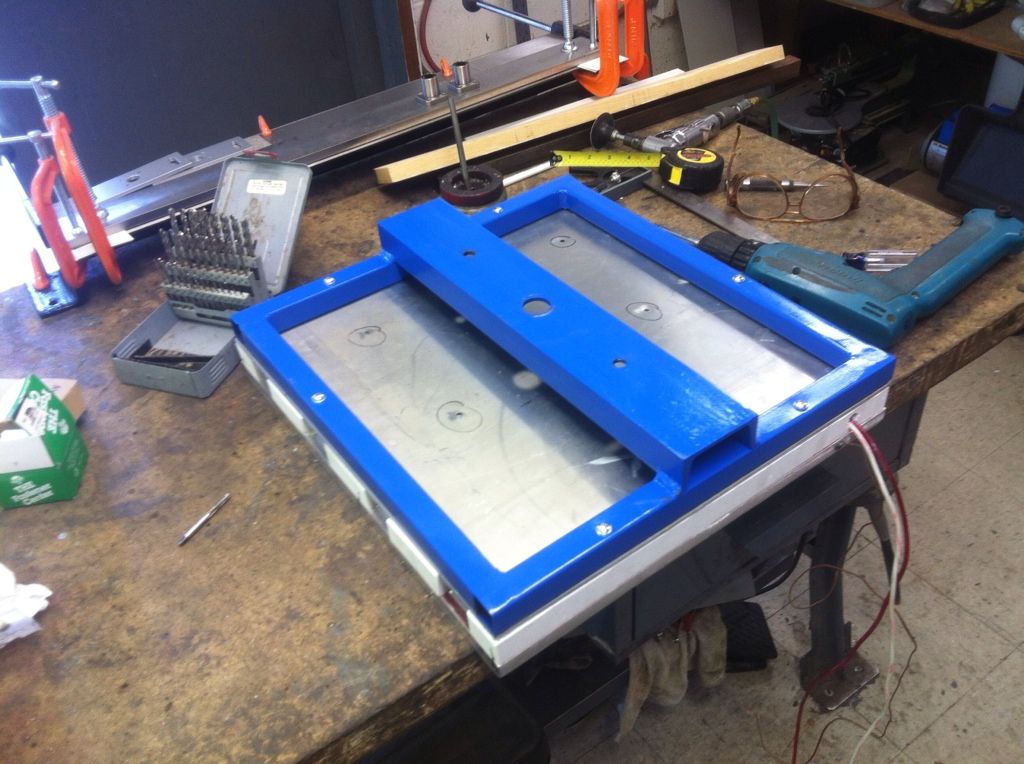

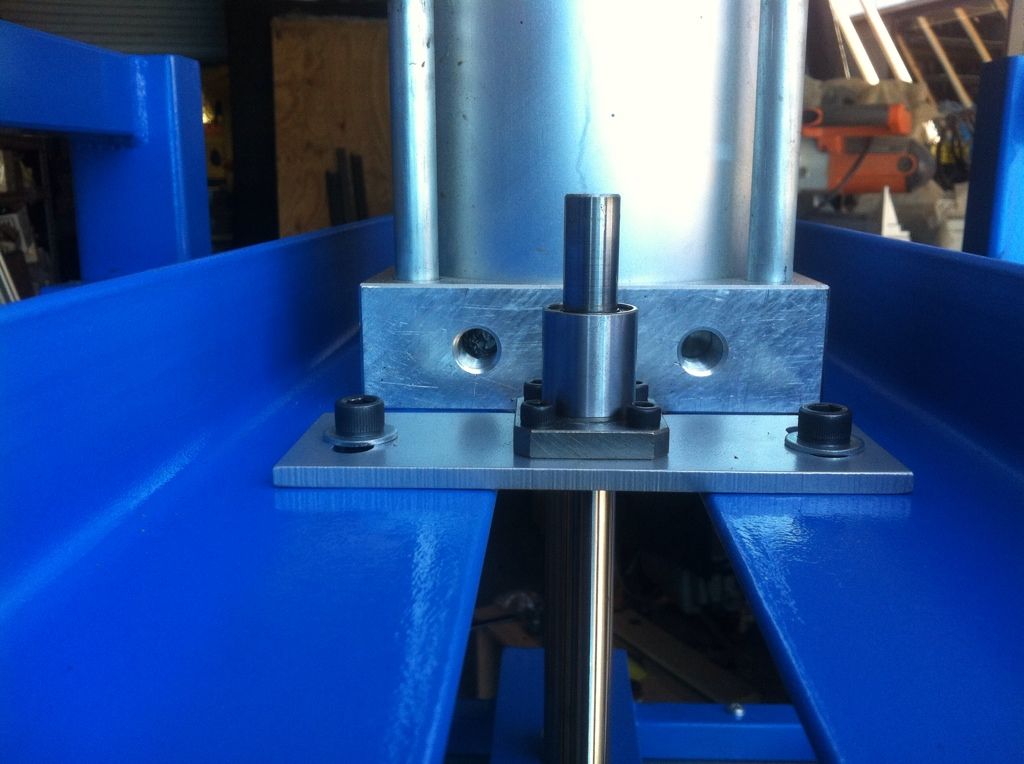

2 aluminum brackets I milled to hold the rod that guided the heating plate. PC'd silver from PBTP.

You can see the 2 alu brackets guiding the rods.

Sorry for the iPhone pics, it was all I had.

I'll keep this thread updated for those who care ;)

I'm using recycled metal from a huge horizontal band saw. I'll let the pics do the talking.

HF casters... ;)

This is the frame for the bottom. An alu plate will be bolted on and leveled out. This will sit in the middle of the whole frame and be secured to the sides of the frame via bolts.

This is the piece that will hold the aluminum heater plate and push it down.

Here's the heating plate with that piece attached

Starting to take shape

2 aluminum brackets I milled to hold the rod that guided the heating plate. PC'd silver from PBTP.

You can see the 2 alu brackets guiding the rods.

Sorry for the iPhone pics, it was all I had.

I'll keep this thread updated for those who care ;)

Comment