Thread needs this...

The Wooden Boat Thread (picture heavy)

Collapse

X

-

That's some great talent for woodworking you have there. How long have you been doing this for?

You sure don't see that many wooden boats out there nowadays.

Just imagine being out on the river and seeing what looks like a viking ship.Zinno '89 <24v swap in progress>

Comment

-

That is so bad ass!

Depends on where you are. Over here on the west coast there are still a good amount of small wooden craft floating around. I also know that there are a lot of wooden fishing boats on the west coast and in Alaska. I am sure there are towns on the east coast with lots of smaller wooden boats and fishing boats as well.

They do need more work and caring for, but I just feel like there is something special about them. The smells sounds and sailing/motoring you get from a wooden craft are very special. Kinda like a e30 or 2002 ;)

Sure the new glass and metal boats are great, but its always sad when a technology like wooden boats is lost in the name of progress. I feel like skills like carpentry or blacksmithing some how define some part of what it is to be human. More so then cooking carbon fiber in an oven with a computer. Something about actually getting your hands dirty, and creating something that has imperfections but is perfect as a whole. Craftsmanship. I think thats something that has been lost on a large level in the modern world, along with actual pride and love for ones work.sigpic

"The bitterness of poor quality remains long after the sweetness of low price is forgotten."

Comment

-

I have a whole tone of pictures and updates coming up. Always takes me a

Secon to get them from my iPhone to photobucket and on to R3V in order with the proper descriptions.sigpic

"The bitterness of poor quality remains long after the sweetness of low price is forgotten."

Comment

-

I love boats. I bought my first boat when I was 17 with my illegal activity funds and we took it wakeboarding every day or so for months and months in the summer time.

I will always appreciated a good boat made of wood. It gives me wood thinking about wood.world renown Harry Potter expert

sigpicComment

-

-

Tomorrow nightsigpic

"The bitterness of poor quality remains long after the sweetness of low price is forgotten."

Comment

-

Here we go...

Ok I will start with the smaller of the three White Halls we are building for the BBC/Discovery Channel.

Sins my last update the White Hall has been completely planked. We did planking from the top and bottom at the same time instead of working our way down in one direction. While a bit more tricky at the end, this method allows four guys to be working on planks at the same time so it speeds up the proses of planking, and also keeps more people busy. At the end you have to do what is called a "shutter plank" which is a plank that has to fit in between to other planks. The proses of spiling for (if you dont know what spiling is look it up, its fun) the plank is a bit more complicated, and then getting the plank to fit in is fun as well.

So here you can see us planking from the top and bottom at the same time.

Then in no time it was time for the last two planks! The shutter planks. The planks are like noodles when they come out of the steamer hahaha

And last but definitely not least, the whiskey plank. The last plank on any boat is always the whiskey plank and is marked with a small celebration, a toast, and a shot of whiskey for everyone.

So this week we have been working on fairing the planks with planes to get the hull round instead of it being a octadecagon.

We are about ready to start calking the seams with cotton.Last edited by deutschman; 03-19-2013, 04:46 PM.sigpic

"The bitterness of poor quality remains long after the sweetness of low price is forgotten."

Comment

-

Now for the Davis Boat. It got final sanded, and had a coat of primer put on. Then we flipped her around and started on the inside of the boat. I'v been working on that mostly by my self. This Japanese kid has been helping me but hes a bit of a young kid and slacks off easily. Anyways...

Put in the thwart risers which are the long stringers that run the length of the boat at the bottom which the benches (thwarts) get fastened to. Then I started on the breast hook, and the thwart knees. The thwart knees are these L shaped brackets that help fasten the thwarts to the hull of the boat. Masaki, the Japanese kid, is suppose to be working on the transom knees but yeah... 4 days and still almost no progress. I think I am going to steel his job from him tomorrow.

The Davis Boat finish sanded.

Here is the progression of the breast hook I made, which is a piece that goes in right behind the back of the stem along the sheer.

Tight fit! :)

You can not really see it but there is a rolling standing bevel on that U curve from 6-15-6 degrees. That was fun. I love making pieces like this.

I forgot to take pictures of the proses of making the thwart knees, but it was much the same as the breast hook and they are even close to done, so I can take pictures tomorrow.sigpic

"The bitterness of poor quality remains long after the sweetness of low price is forgotten."

Comment

-

Now for the lapstrake boat we just started. On lapstrake boats the planks, or strakes in this case, over lap each other instead of butting up against each other. This will be our first lapstrake boat. I helped make the molds with my buddy Griffin and also made the transom out of some biscuit joined Sapele.

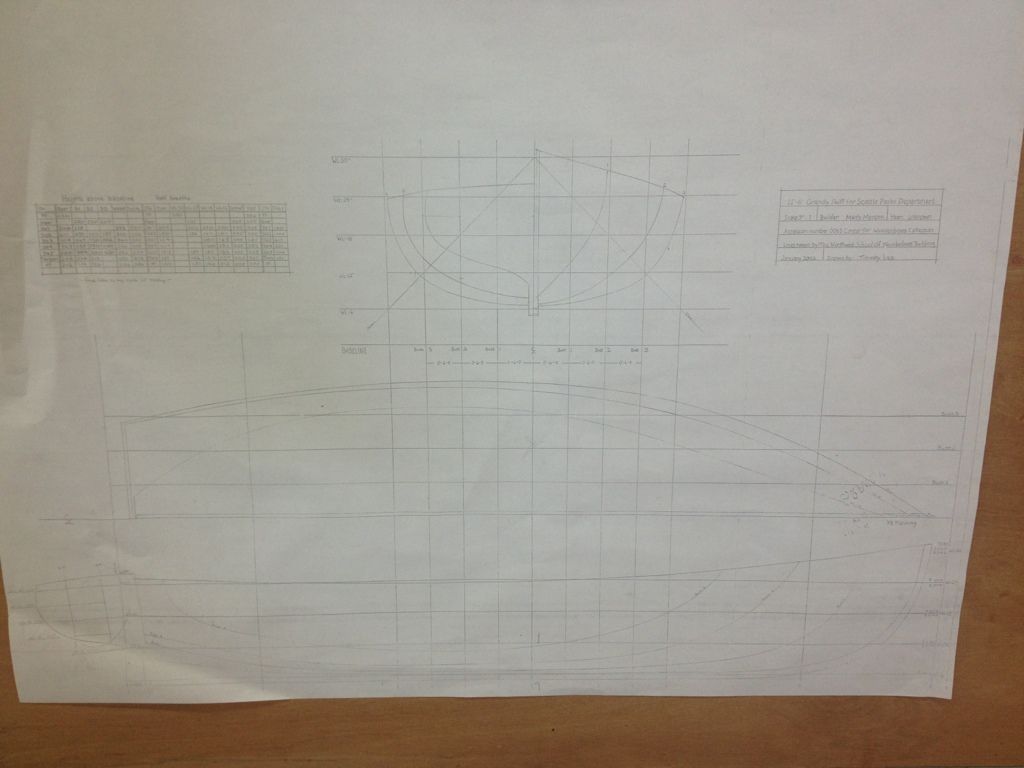

Here is a drafting of the boat.

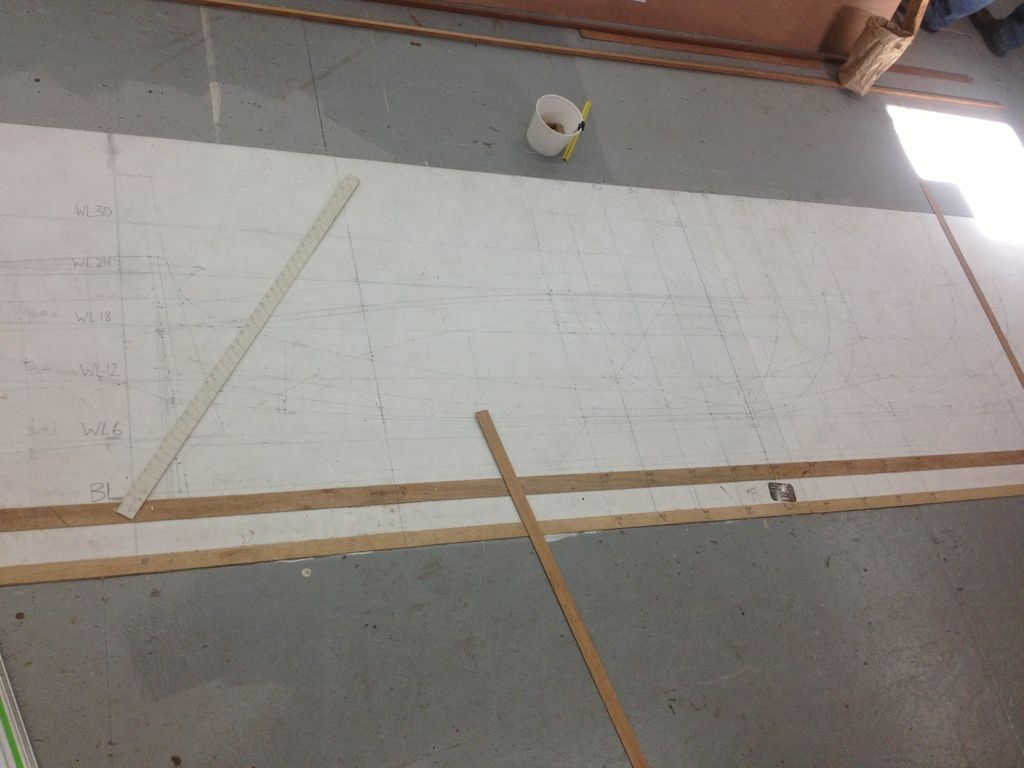

We then take the drafting and loft it out full scale on some door skin.

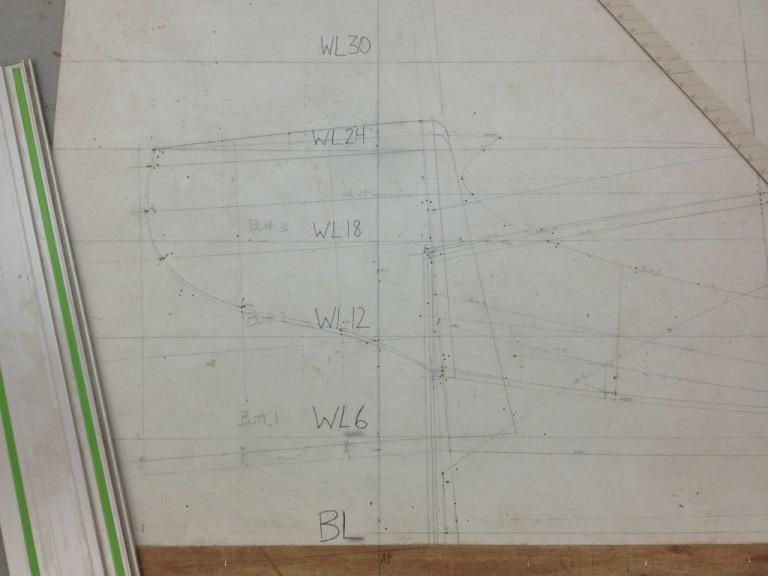

Body lines, cross sections, stem, and transom plus a few other developments.

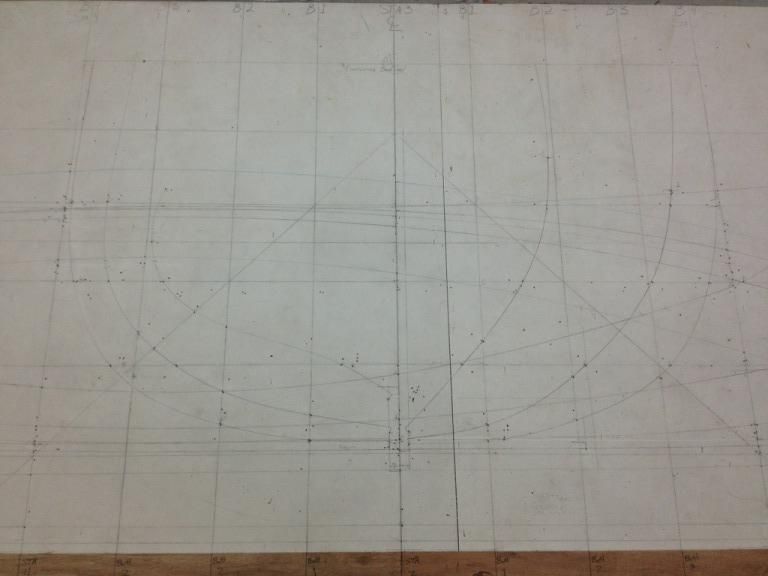

Cross sections.

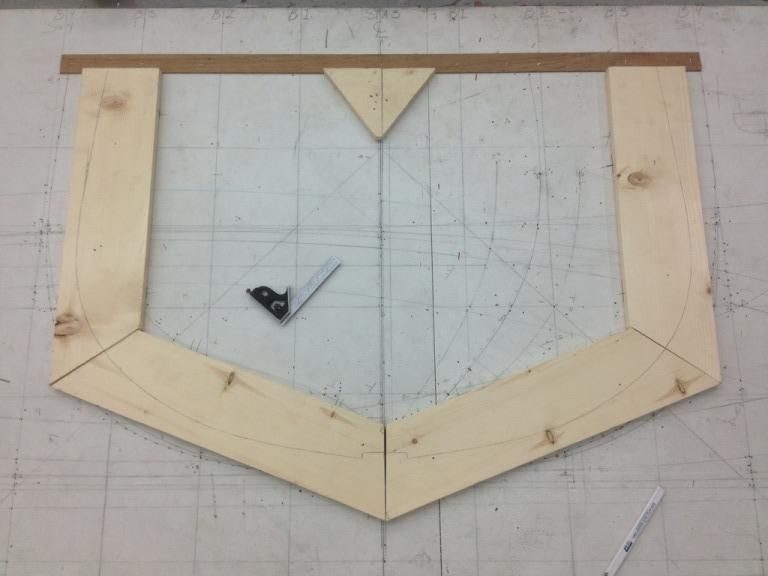

Transom.

Stem.

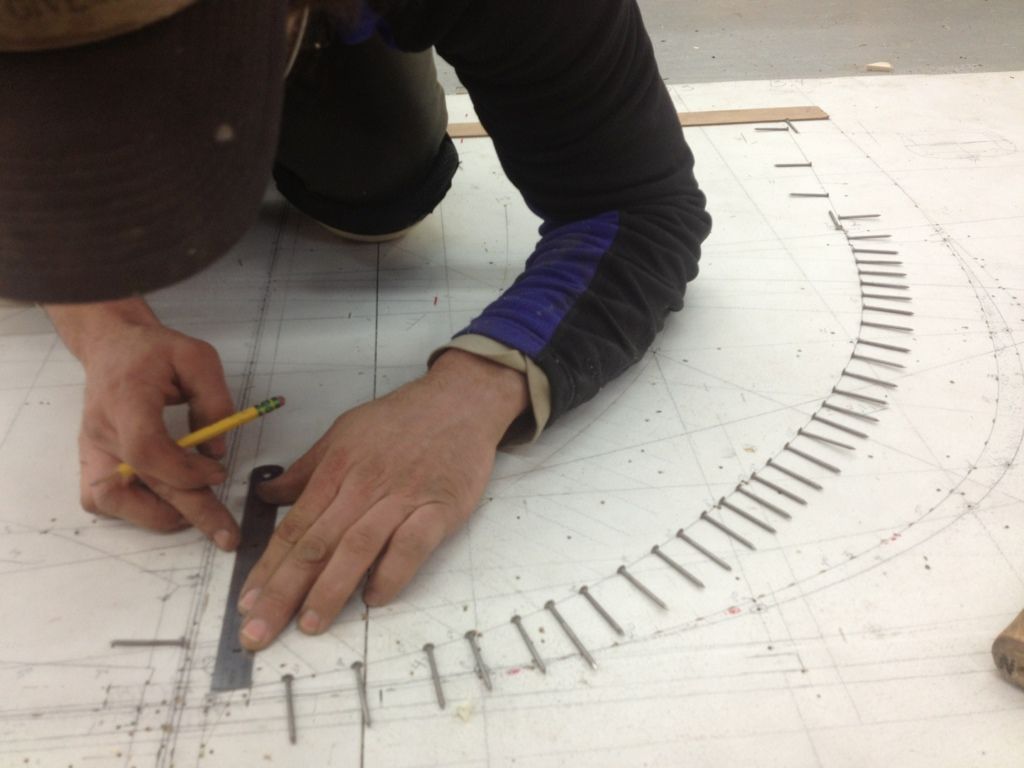

Then we use the cross sections to make the molds for the boat. There are a few methods, but for small boats this method works well. You just put some nails along the lines and sink the heads in. Then you take a piece of door skin about the size of half the cross section and lay it over the nails. Do a little dance on the door skin, lift it up, and you have a perfect out line of the cross section on the piece of door skin. You can then cut the shape out and use it as a template for your mold.

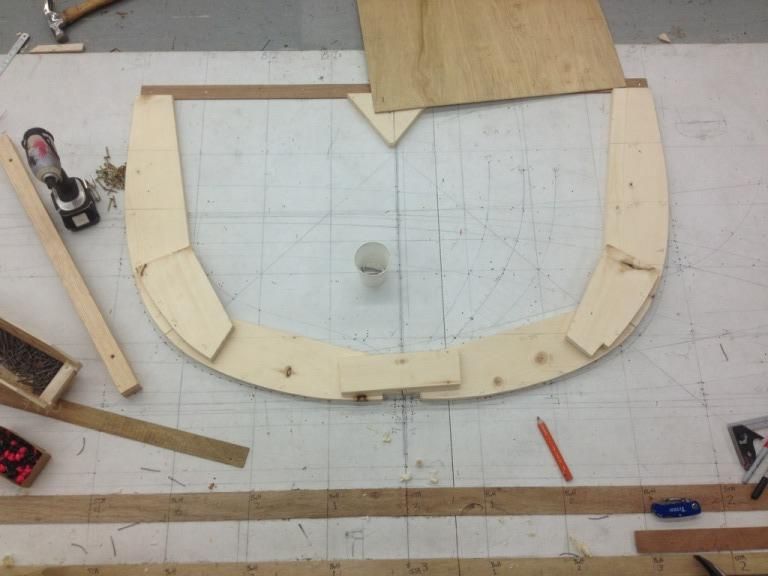

Then Griffin put all the molds up on a strong back, ready for the boat to be built around the frames. Some other guys made the keel, apron, stem, and stern post. I made the transom.

Then all those parts got put together, and went on the molds.

Keel and apron.

Stern post.

Stem.

Transom.

Everything up on the molds.

Thats where we are with that boat. Just starting the proses of spiling for the first two planks.sigpic

"The bitterness of poor quality remains long after the sweetness of low price is forgotten."

Comment

-

-

Ok and finely for some random shit. The guys next door are working on this contemporary craft. Its a sentinel class 24" day sailor, thats about all I know. The keel, frames and transom are all laminated. The hull is strip planked with bead and groove, then two layers of thin laminate are vacuum bagged on, and then finely it gets glassed.

Bead and groove plank.

There ghetto rigged dual router table to cut a bead and groove at the same time ;)

Planking.

Laminate going on with plastic staples.

Laminate being vacuum bagged.

They got both sides done, and I will be helping them glass the hull tomorrow.

Here are some blocks that Paul has been making for The Adventures (http://www.soundexp.org/index.php?page=our-ship) as a side project.

And a backing out plane I started on. Backing out planes have a rounded bottom to back out planks so that they fit over rounded frames.

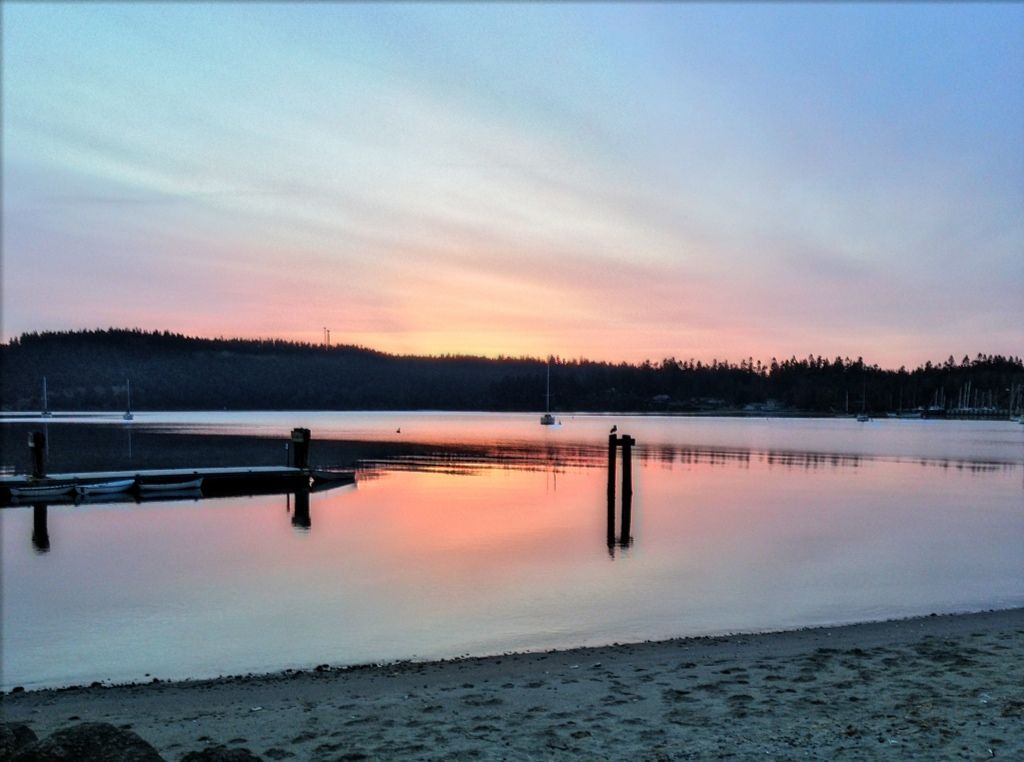

And last but not least, a picture of the sun rise at 7:02 this morning.

Thanks for reading!sigpic

"The bitterness of poor quality remains long after the sweetness of low price is forgotten."

Comment

-

sigpic

"The bitterness of poor quality remains long after the sweetness of low price is forgotten."

Comment

Comment