I built this one a couple years ago and it's been doing a solid job of daily use.

But unfortunately, it isn't big enough for what we need it for. We are going to start doing 4x8 sheets of sublimated metal prints. Here's an example of an aluminum print: (roughly 28"x40")

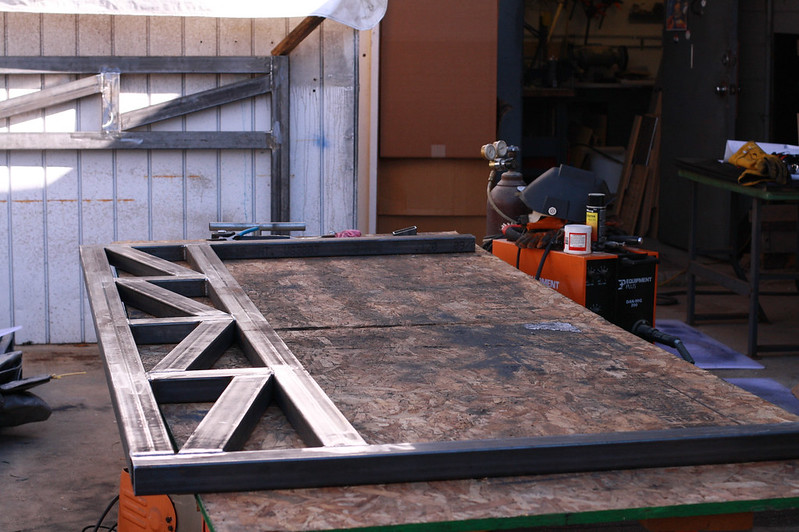

So here's the new press I'm building. I just started today and only had an hour or so of time. It will be able to do full 4x8 sheets.

But unfortunately, it isn't big enough for what we need it for. We are going to start doing 4x8 sheets of sublimated metal prints. Here's an example of an aluminum print: (roughly 28"x40")

So here's the new press I'm building. I just started today and only had an hour or so of time. It will be able to do full 4x8 sheets.

Comment