Here is my new project. Its going to a be tool storage shed/mini work shed based on a Harbor Freight 94564 trailer.

I decided on this a few days ago, and after a few days of brain storming and going back and forth on other options I finally made up my mind and grabbed the trailer today.

Basically I need the trailer for three things.

First I work construction and need a place to keep my ever growing colection of tools. I live in a tiny place and have no storage, so this will help a lot. Second I am moving to the PNW early next year and need some extra room to put stuff during the move. The U-Haul trailer rental was almost the same price as the HF trailer.

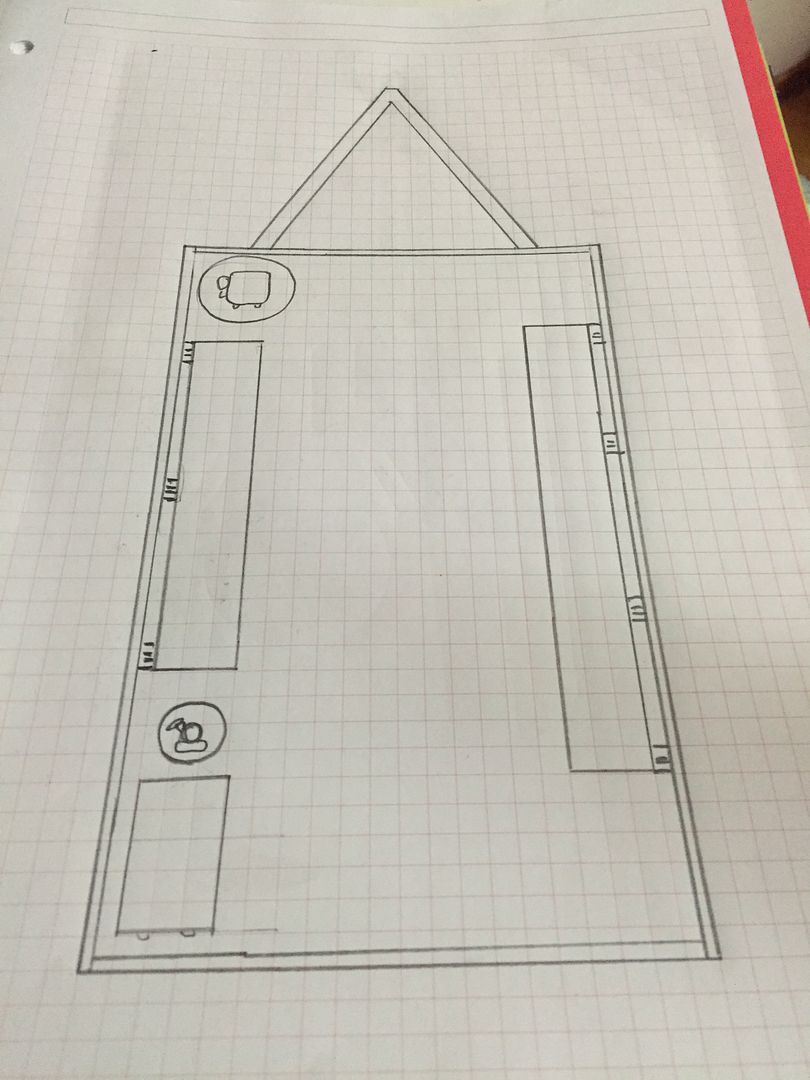

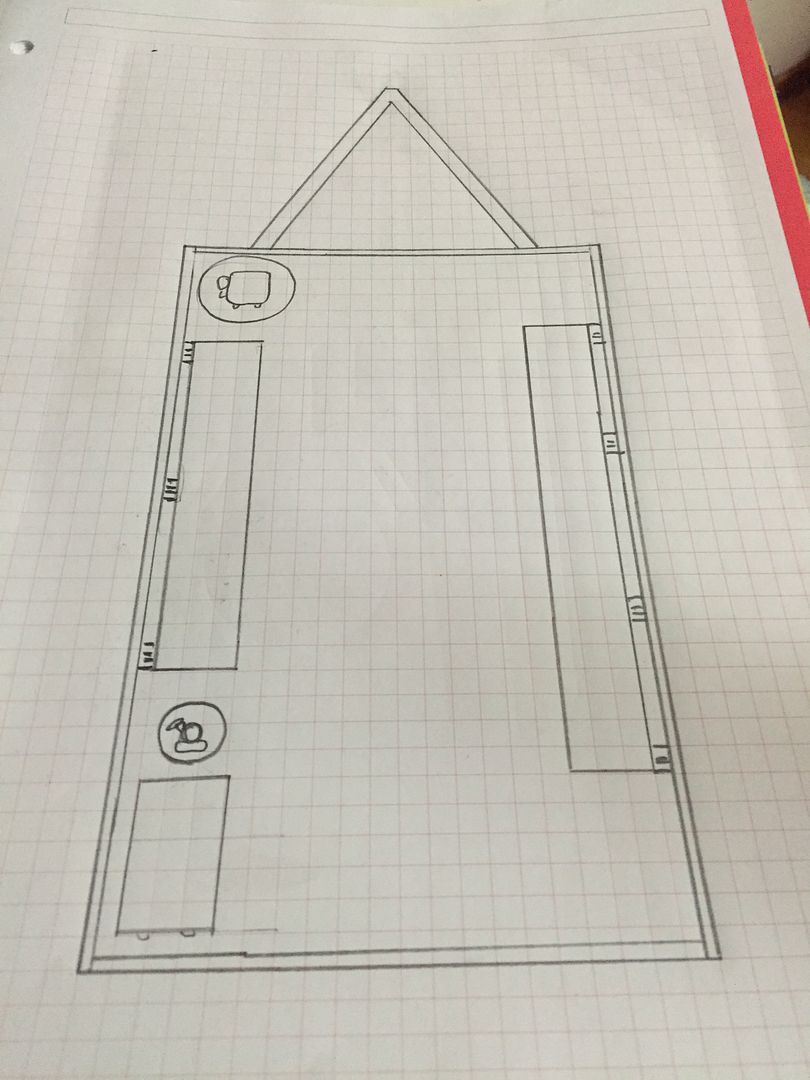

Third, I plan to build in a few small space saver folding work benches, some hardware/electrical/tool storage boxes, a space for my MIG welder, and maybe my small pancake air compressor so I can use this thing as a sort of moving work space for my self and work projects. Eventually I want to get a small generator to power some lights and tools like the welder which is a 220amp welder.

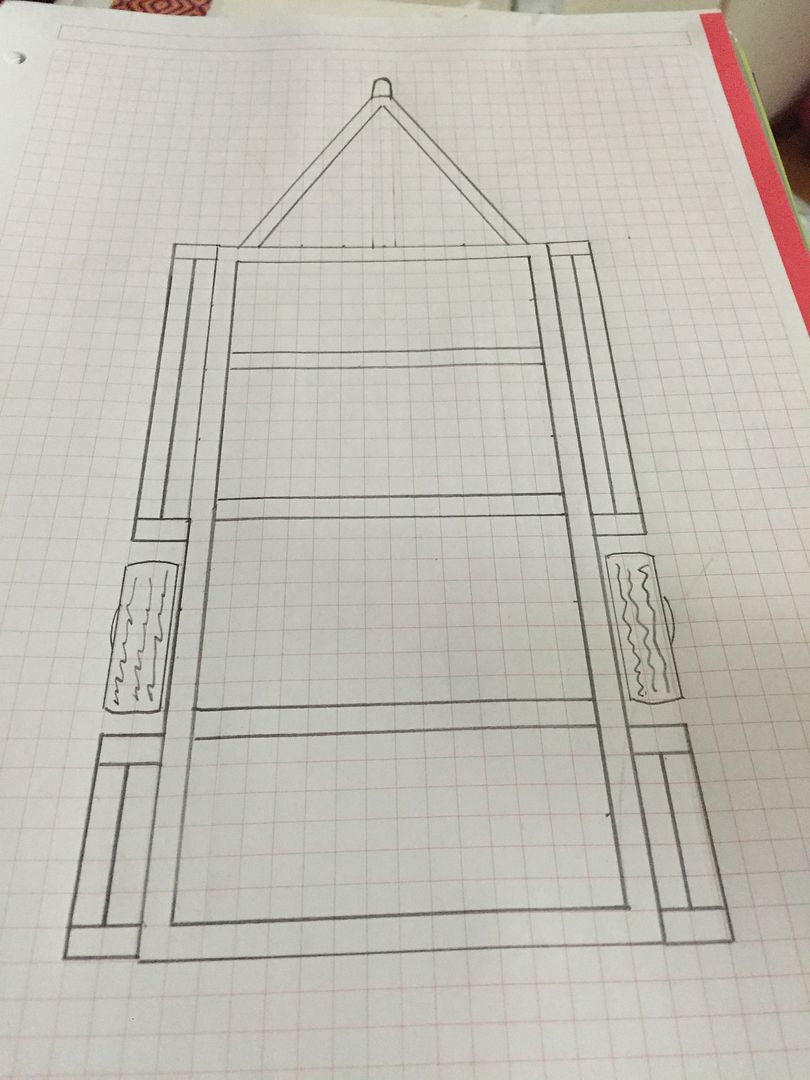

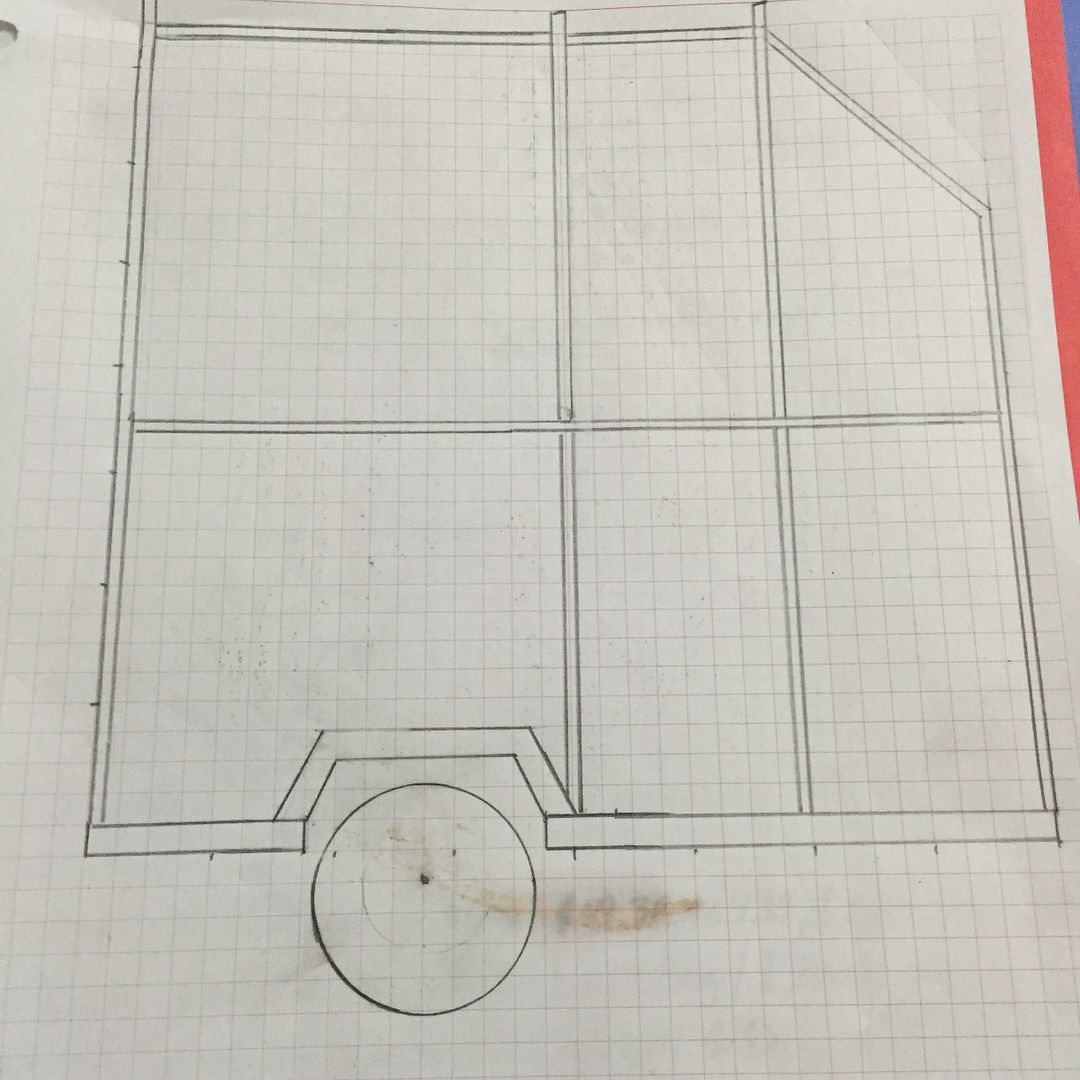

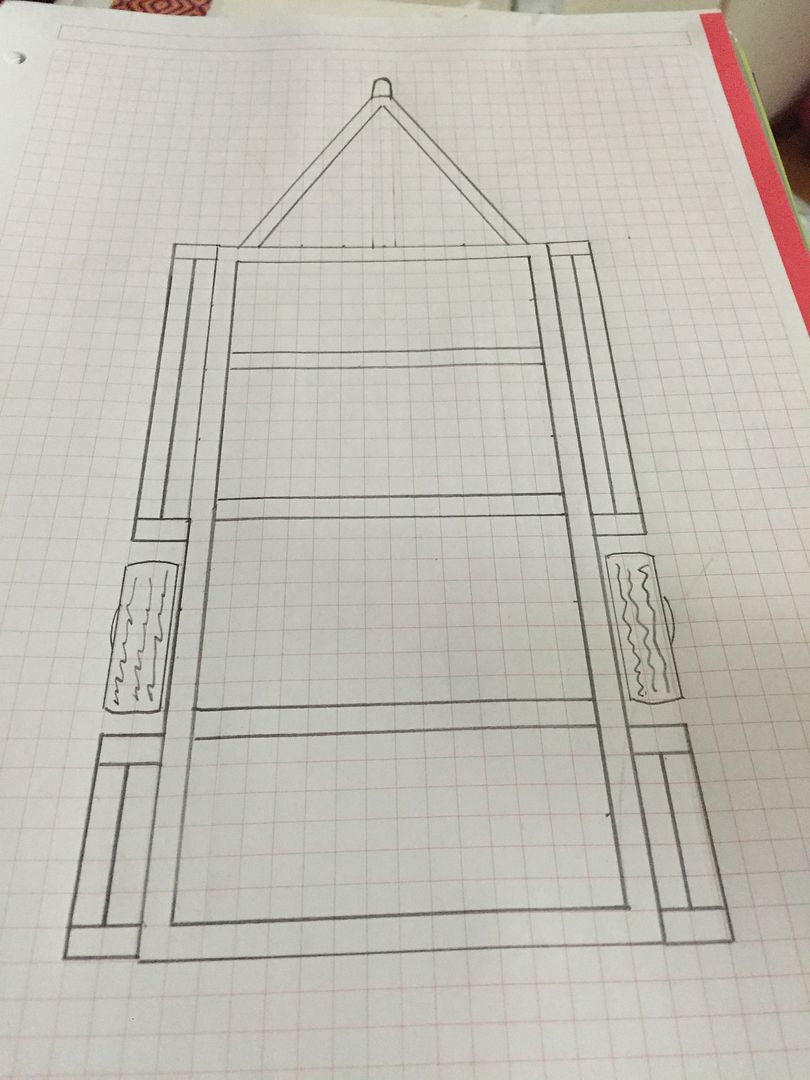

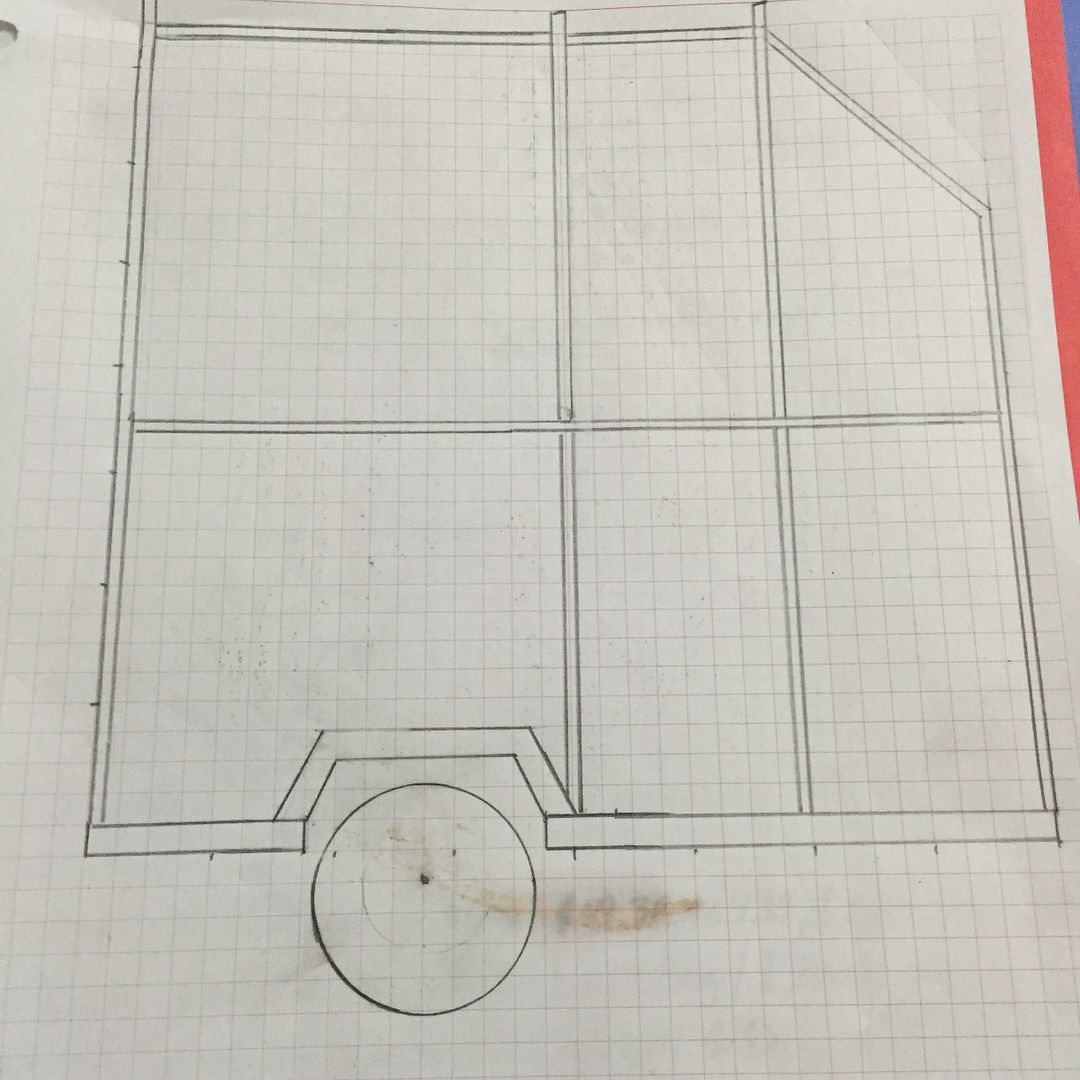

The basic HF trailer has a useable space of 48x96" and can pull 1720lb. I intend to add about 10" inches to each side by adding out riggers that stick out flush with the wheels. Then I am going to weld up an enclosure of 1x1" square tube.

I am not quite sure what I am going to skin the enclosure with. I was thinking aluminum sheet, but does anyone ells have any other ideas? It needs to be strong so no one can easily cut through it, it needs to be light and weather/corrosion resistant, and of cores as cheap as possible.

Those are the basics for now. The rest of the planning will be done on the fly I think. Not everyone can work like that but I usually do well planning as I work and think things through. Ill get the basic frame all welded up and than plan the rest of the project.

Here are some basic ideas of the first steps. Subject to change of cores.

I extended the vertical frame pieces up a bit so they can be used as a sort of roof rack for adders and stuff, but I might just go with a bolt on solution for that which will making wrapping this thing in a skin easier.

Anyone have any ideas, recommendations, hesitations, comments, and or degrading dribble please feel free to share as usual. It is R3V after all

I decided on this a few days ago, and after a few days of brain storming and going back and forth on other options I finally made up my mind and grabbed the trailer today.

Basically I need the trailer for three things.

First I work construction and need a place to keep my ever growing colection of tools. I live in a tiny place and have no storage, so this will help a lot. Second I am moving to the PNW early next year and need some extra room to put stuff during the move. The U-Haul trailer rental was almost the same price as the HF trailer.

Third, I plan to build in a few small space saver folding work benches, some hardware/electrical/tool storage boxes, a space for my MIG welder, and maybe my small pancake air compressor so I can use this thing as a sort of moving work space for my self and work projects. Eventually I want to get a small generator to power some lights and tools like the welder which is a 220amp welder.

The basic HF trailer has a useable space of 48x96" and can pull 1720lb. I intend to add about 10" inches to each side by adding out riggers that stick out flush with the wheels. Then I am going to weld up an enclosure of 1x1" square tube.

I am not quite sure what I am going to skin the enclosure with. I was thinking aluminum sheet, but does anyone ells have any other ideas? It needs to be strong so no one can easily cut through it, it needs to be light and weather/corrosion resistant, and of cores as cheap as possible.

Those are the basics for now. The rest of the planning will be done on the fly I think. Not everyone can work like that but I usually do well planning as I work and think things through. Ill get the basic frame all welded up and than plan the rest of the project.

Here are some basic ideas of the first steps. Subject to change of cores.

I extended the vertical frame pieces up a bit so they can be used as a sort of roof rack for adders and stuff, but I might just go with a bolt on solution for that which will making wrapping this thing in a skin easier.

Anyone have any ideas, recommendations, hesitations, comments, and or degrading dribble please feel free to share as usual. It is R3V after all

Comment