Those are titanium, fine-pitch hollow fasteners which I intend to use for the scales. I used stepped drill bits to cut the inset in the scales' mounting holes for the fasteners to have a near-flush mount.

Knife Thread: All about Knives and other edged tools

Collapse

X

-

I felt like a shop chopper should be heavy and balanced, so I wanted copper liners for the scales to offset the blade weight. First, I had to make brass threaded inserts to mount the scales. Did this with my bench lathe and some hand tools. Then cut some copper sheet to fit the handle. Scales will be a nice jade-colored G10 material. When the copper oxidizes, it should match nicely.

Those are titanium, fine-pitch hollow fasteners which I intend to use for the scales. I used stepped drill bits to cut the inset in the scales' mounting holes for the fasteners to have a near-flush mount.

-

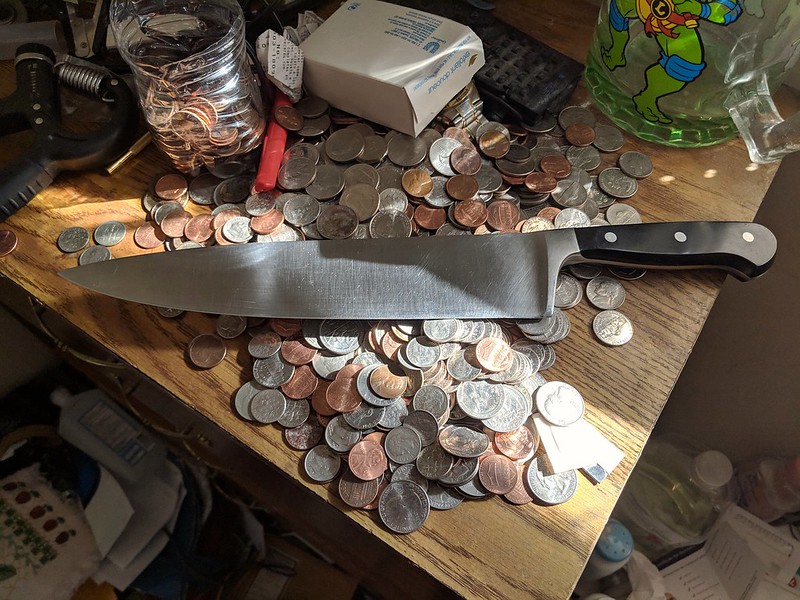

Then I decided to get a little more serious. I wanted a shop knife, a bad-ass chopper that I could beat on and not worry about. I stuck with 0-1 tool steel since it's good stuff and I already bought a bunch for this new winter hobby.

Took some home-made clay, and squeezed it to shape a grip. Cut the pattern on the steel using my band saw and bench-top mill with a carbide burr. Decided I like the look and feel of thumb jimping on the blade spine, so I cut those on the band saw as well. That other blank is another blade I was making simultaneously, experimenting with a Wharncliffe type blade.

Leave a comment:

-

The blade has to be heat-treated, so I made a forge out of an old charcoal chimney starter, bolted on some screws for legs, lined with mixture of plaster and sand, insulated with fiberglass furnace matting. Fired with a butane torch. Quenched in some old cooking oil. Then tempered in a cheap toaster oven I bought on Amazon just for this purpose.

Leave a comment:

-

-

Like many other knife enthusiasts, I was inspired by that show Forged in Fire. We don't have cable TV, I only caught a single episode while staying at a hotel. While watching, I decided that if those neck beards can make knives, then so could I.

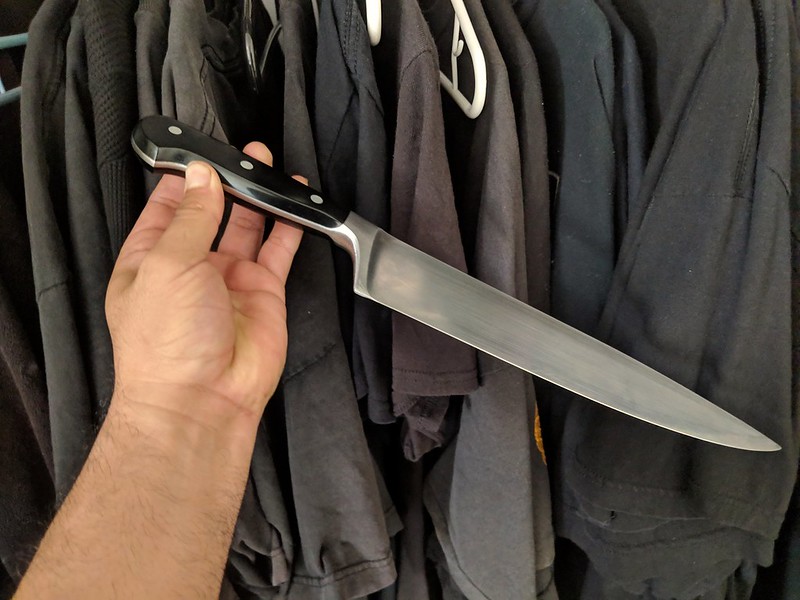

Using 0-1 tool steel, I went easy for my first attempt by making a heavy Nakiri type blade with a handle patterned after one of our Wusthofs.

Leave a comment:

-

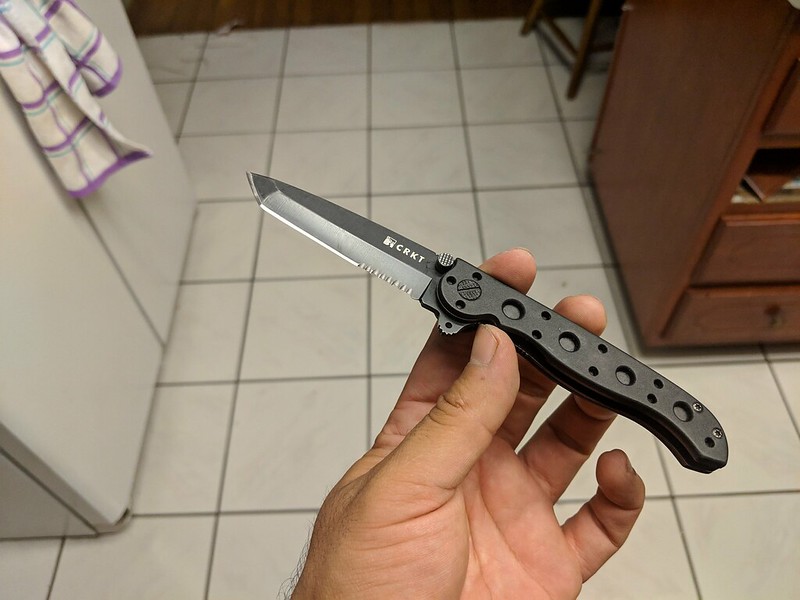

this crkt is ok but the handle is too thin and the safety for the lock is stupid.

Flipper by jet jones, on Flickr

Flipper by jet jones, on Flickr

Crkt by jet jones, on Flickr

Crkt by jet jones, on Flickr

this kershaw is ok too. i like the blade shape, it has the nice "shhik" when you flip the blade out

but it's made in china. huh?

Kershaw by jet jones, on Flickr

Kershaw by jet jones, on Flickr

Leave a comment:

-

sweet knives

what is that little one bottom right next to teh filletLeave a comment:

-

Brought this guy out of retirement yesterday. Lost my HK/benchmade and sadly it's now discontinued. Almost bought a new benchmade and remembered I had this tucked away.

Spent about an hour bringing it back, now I just need to get some screws to replace the couple that have gone missing.

Leave a comment:

-

reviving this thread since i added to my collection recently:

left to right:

deerhorn knives from china, not finished yet

short katana

ak47 bayonet i picked up in iraq

gil hibben dagger

kukri machete from tibet

ww1 bayonet (german)

bring on the fucking zombies :PLeave a comment:

-

It didn't occur to me until the other day that my Hubertus auto and my E30 are both German and about the same age too, my Dad gave me this and IIRC he bought it in the very early '90s.

Leave a comment:

-

Oh you said assisted.

Na, just these normal ones.

Leave a comment:

Leave a comment: