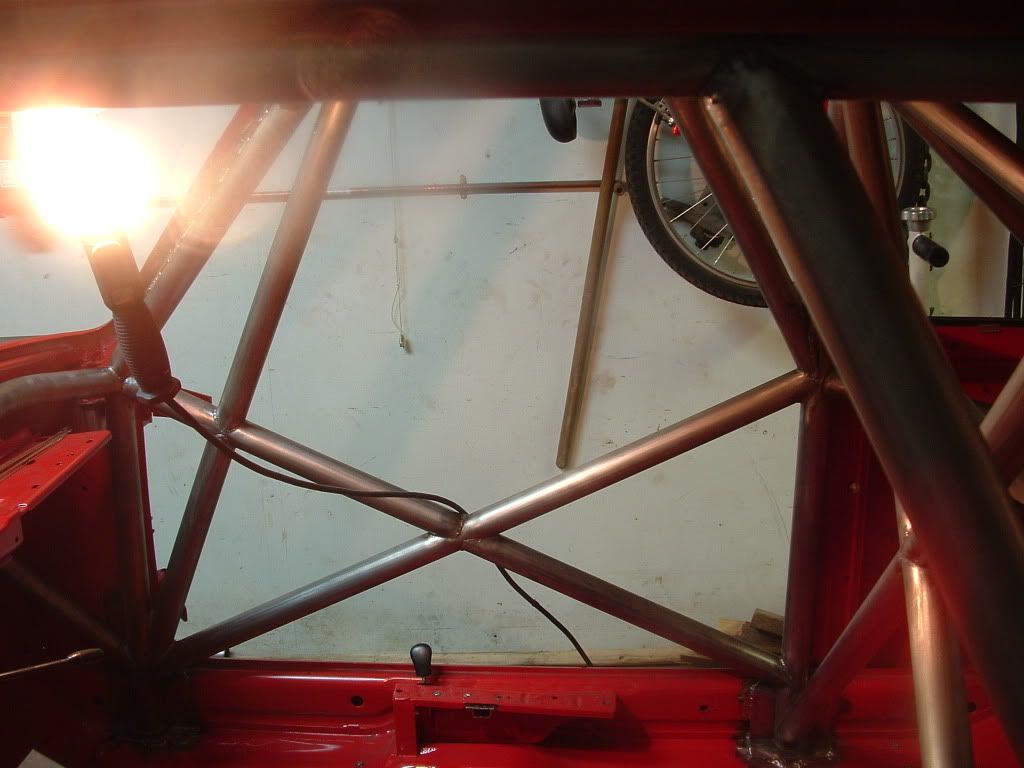

My friend used a Tig which makes nicer welds than a Mig. He's experimented, but not a pro welder.

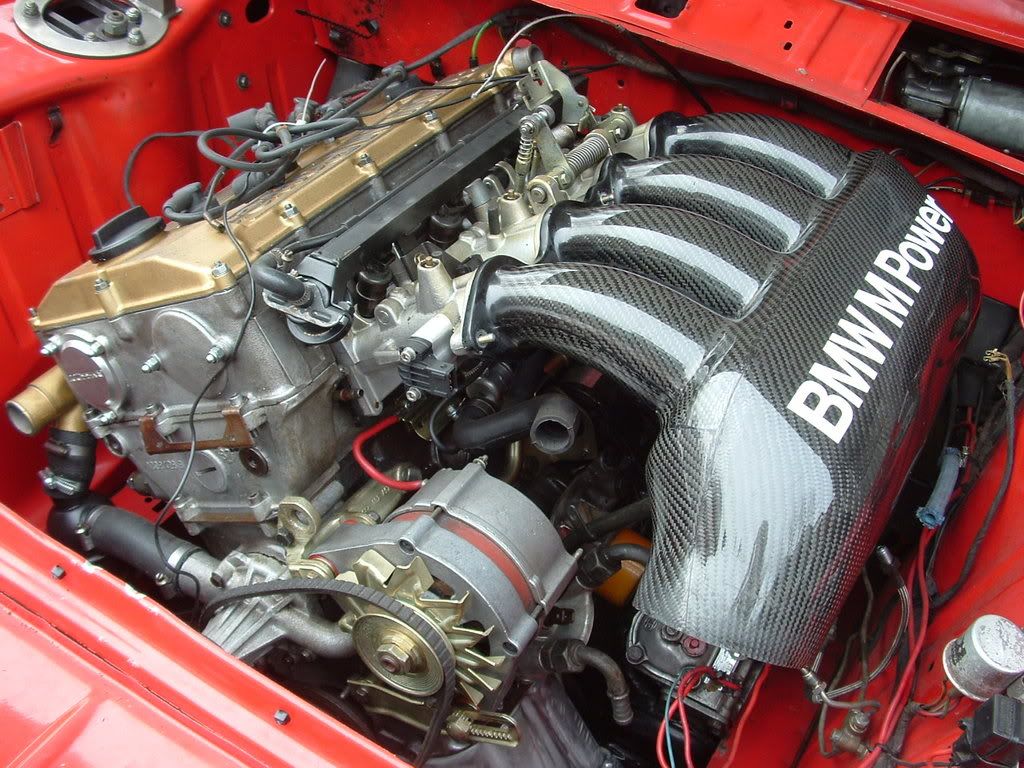

Test fit was to ensure I could fit the box, as the engine is set-back by 1.5", and to verify I can use the CF snorkel (air collector).

Lee

Rollcage project - M2

Collapse

X

-

very nice welds

how many years of experience does it take to achieve such clean welds?

Did the test fit come out good?Leave a comment:

-

Here are some more shots. The passenger side strut tower tube is not yet fully welded. But you get the idea. Pictures were taken this afternoon before I did the first coat of paint.

Last edited by Massive Lee; 02-17-2009, 01:28 PM.

Last edited by Massive Lee; 02-17-2009, 01:28 PM.Leave a comment:

-

There's no possibility to have the dash bar straight. Over the dash tray, I would loose my instrument cluster. and under the dash tray, I can't remove/fix my heater box. The way it is now, it will be gussetted at the junction of the A pillar and base of winsdhield frame, and gussetted on the firewall. Which will stiffen and reinforce the whole front end.

DC - I would be quite happy to collaborate in some sort of way but distances can make things difficult indeed.

LeeLeave a comment:

-

Hey Lee,

Is this something you would want to go into... and can you work from Solid Works?

I have wanted to produce a bolt in 6 point for the e30 for a while now but although they dig my design concept nobody I know wants to risk putting the work into it.

We are kind of far apart to collaborate though.Leave a comment:

-

That looks like a hell of a cage.

However, everything I read about cages claims that the dash bar shouldn't be bent. Are you constrained by the chassis?Leave a comment:

-

Fuck you, I hate you!

Haha j/k, looks great, keep up the good work Lee.

AndyLeave a comment:

Leave a comment: