Where is everyone mounting their s54 swap ecu?

Collapse

X

-

looks tidy, nice work, Brad.Leave a comment:

-

Here is my DME Setup. The DME box was purchased out of the country. Definitely a nice piece to be able to mount the DME in the factory location. I had to trim the Glovebox trim pieces to fit around all of the wires, relays and box itself. See pictures attached5 PhotosLeave a comment:

-

No photos, just wondering why no mention of the E39 harness- it's nice and looong.

edit- reading comprehension, S54, NOT M54

doh.

tLeave a comment:

-

Had this issue in my 95 318ti S54 swap. Ended up extending the loom wires (30+ wires), but will be replacing that mess with another loom to try flipping it.Leave a comment:

-

Nice work, looks good. If you look at the 2nd to last page (p10) of my thread, I actually had to drop the motor & subframe after realizing that the harness has to be squeezed past the cylinder head. I had it draped over the bellhousing during installation.Okay. I looked at your build thread and got jealous of all that wiring poking into the glovebox so I decided to give it another go. I have it running right above the valve cover and I agree that there won't be much rubbing/heat there. With that plus the flip I am getting just enough in the glovebox to be able to connect everything and close it. It's not perfect but it's a heck of a lot better than having that rats nest sitting in my battery tray. I was able to bring everything in except for the relays and get it all connected. Did a test fire up and everything is still working as it should.

Thanks for motivating me to try it. I'd say doing this with the e46 m3 harness definitely works. I don't have as much wiring as butters but maybe that's because he used a z4m harness?

I am running the E46 harness as well, and it looks like so much more wiring in the cabin because I've already pushed in the relays. It's not as hard as it seems, there's plenty of length (as you can see) and wasn't much struggle getting each individual relay through, one at a time.

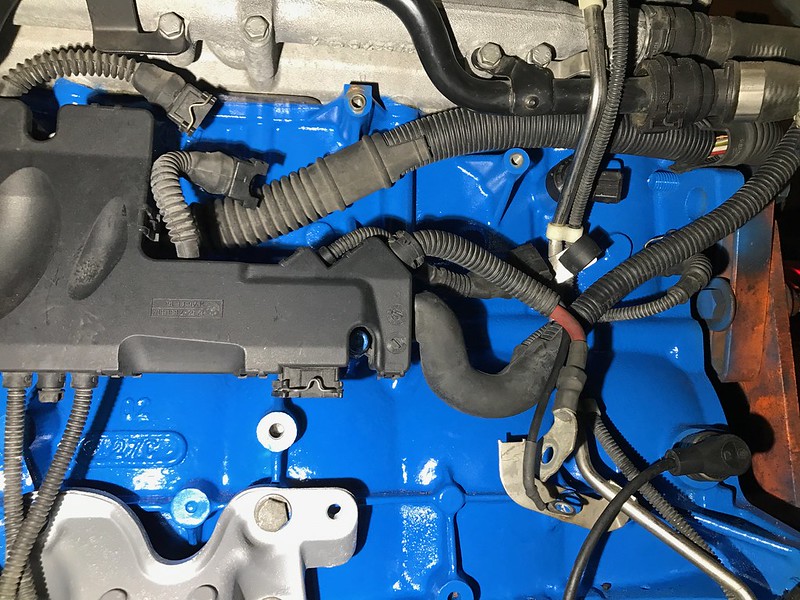

You can see in this photo where my main loom pokes up and over the "battery tray" from behind the cylinder head. I could probably pull it up into a position like yours, but I'm actually going to see if I can somehow park the DME in the E30/M42 bracket for that factory finish.

Leave a comment:

-

Okay. I looked at your build thread and got jealous of all that wiring poking into the glovebox so I decided to give it another go. I have it running right above the valve cover and I agree that there won't be much rubbing/heat there. With that plus the flip I am getting just enough in the glovebox to be able to connect everything and close it. It's not perfect but it's a heck of a lot better than having that rats nest sitting in my battery tray. I was able to bring everything in except for the relays and get it all connected. Did a test fire up and everything is still working as it should.I see where you're coming from concerning the vibration, but from my experience the main loom has to run the shortest distance possible to the gloveboxl. The result is that it's sandwiched between the cylinder head and the firewall, below the plastic tray. The plastic cover over the firewall hole will still hide it.

We have to trust that the vibration and heat is no greater than what the rest of the harness experiences being bolted to the block on the intake side.

You'll also need to remove most of the rubber/foam sheathing to get rid of its bulk.

Thanks for motivating me to try it. I'd say doing this with the e46 m3 harness definitely works. I don't have as much wiring as butters but maybe that's because he used a z4m harness?

Here are some photos of it installed:

Leave a comment:

-

I guess I'm more hesitant because I've had an injector wire harness wear out on the road leaving me stranded. It took forever to find the wire that wore down and was grounding.I see where you're coming from concerning the vibration, but from my experience the main loom has to run the shortest distance possible to the gloveboxl. The result is that it's sandwiched between the cylinder head and the firewall, below the plastic tray. The plastic cover over the firewall hole will still hide it.

We have to trust that the vibration and heat is no greater than what the rest of the harness experiences being bolted to the block on the intake side.

You'll also need to remove most of the rubber/foam sheathing to get rid of its bulk.

I'm not saying this method won't work, but it doesn't appear to be perfect. I think I'm going to opp for leaving my ECU in the battery tray for now and just extending the loom after I get everything else sorted.Leave a comment:

-

I see where you're coming from concerning the vibration, but from my experience the main loom has to run the shortest distance possible to the glovebox. The result is that it's sandwiched between the cylinder head and the firewall, below the plastic tray. The plastic cover over the firewall hole will still hide it.I did the flip in the plastic box on the intake side and I'm running the wires only partially along the plastic tray above the engine (I cut a slit to drop them down before the end). I would think running them against the engine could be problematic - I picture the heat and vibration wearing a wire and leaving you stranded.

My wire only produces about 1.5 inches into the glovebox. I can connect it but it's not going to work because you can't close the glovebox and I feel like there is too much stress on the wires.

Has anyone else got this to work?

We have to trust that the vibration and heat is no greater than what the rest of the harness experiences being bolted to the block on the intake side.

You'll also need to remove most of the rubber/foam sheathing to get rid of its bulk.Last edited by butters; 05-31-2017, 11:13 AM.Leave a comment:

-

I did the flip in the plastic box on the intake side and I'm running the wires only partially along the plastic tray above the engine (I cut a slit to drop them down before the end). I would think running them against the engine could be problematic - I picture the heat and vibration wearing a wire and leaving you stranded.

My wire only produces about 1.5 inches into the glovebox. I can connect it but it's not going to work because you can't close the glovebox and I feel like there is too much stress on the wires.

Has anyone else got this to work? I'm trying to run the early model expansion tank and I'm having a hard time fitting it because I have a wiring mess and the ECU sitting where it needs to go.

Here are photos of my swap in the plastic box.

Before:

After (the main wire is going the opposite way):

Here are pics of the main wiring loom which seems to be the shortest wire:

Wiring going into firewall:

Wiring protruding into the glovebox:

Leave a comment:

-

Once I had the harness in hand I did catch on to how it's done. I failed to take a photo of the back of the plastic box where the change is visible, but if you can imagine the biggest bundle of wires in this photo pointing 180 degrees relative to the box, that's how the e46 harness runs. Unclip the box around its perimeter to open it up, then the rubber can be reversed in its attachment, allowing the bundle to run above the knock sensor, behind the fuel and water lines and then around the back of the cylinder head. Fingers crossed that's all that's needed.

The throttle actuator gets bolted over the loom, nicely tucked.

Leave a comment:

-

Another bump, because I'm not clear on what exactly is meant by "reverse the wiring in the plastic box" even after seeing the photos. I'm hoping this will become more obvious once I get into the wiring.Leave a comment:

Leave a comment: