Okay, so I finally got around to doing this iX wheel bearing job and wanted to post up the process for others to use. I wish I had this info a long time ago – would have saved me so much time. But I have to thank others on the forum that have lent their suggestions and advice…So here’ goes.

Take the hub cap off

Ta-dah!

Axle nut in the middle. Found mine had no lock ring on it.

Keeping the car on the ground, I used a 30mm socket to loosen the axle nut. Put a pipe on the end of a torque wrench and it came off without a problem. I did put some penetrating oil in there first.

Loosen the 4 lug nuts on the wheel

Jack it up

Throw your wheel on a pile of wood

Getting’ there

Back of brake caliper

Disconnect the brake sensor behind the caliper

Loosen the 2 brake caliper bolts. You’ll need a 15mm wrench to hold the inner nut while loosening the outer bolt (17mm I believe).

Take the caliper off and hang it from the loop underneath the car (or some place else) with a short bungie cord or rope. Don’t let the brake line take the weight.

Grab a 19mm wrench and remove the two bolts that hold the caliper bracket

Remove the dust shield – 3 bolts (10mm wrench)

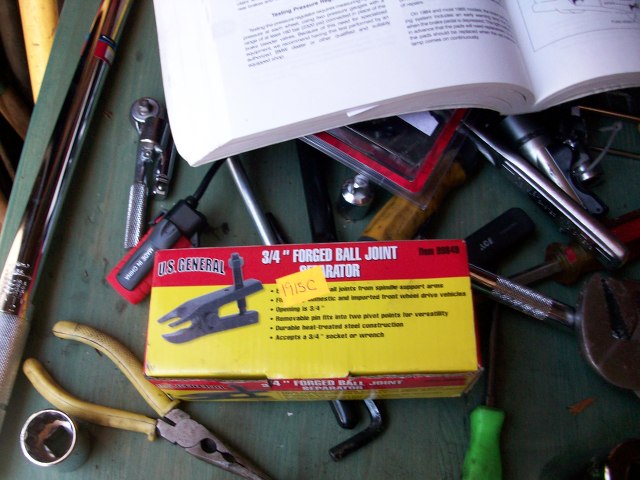

Get ready to remove the tie rod end and control arm ball joints – no biggie really, using the Harbor Freight ball joint separator. Took me a minute to figure out how to use it because it comes with no instructions, but it’s simple. You'll need to loosen the nuts on both ball joints so that they come to the tops of the bolts. Don't remove the nuts yet. Leave them on in order to protect the threads when using the tool. Then simply put the fork portion of the tool above the rubber boot and the single prong piece goes over the top of the bolt/nut. Crank down on the tool using a wrench (you'll see where it goes) and with each turn it’ll squeeeze that sucker out. The control arm ball joint separates with AUTHORITY. Damn – you’ll know it when it happens. Lol

At this point I removed the ABS sensor using an allen tool

Loosen the axle nut the rest of the way

I used a punch like this and a hammer to whack the axle out. Easier than I thought it would be.

I used the stoopid expensive SIR B90 tool to do the work. I don’t know. Maybe it’s worth it. It made the job easy work once I figured out the configuration of all the different parts of the tool. You have to use the tool 3 times for the job – removing the hub, removing the bearing and pressing the bearing.

Pressing out the hub config. Notice where the U-shaped part of the tool is pressing against the spindle. This part took me a minute to figure out.

Hub out. Remove the circlip and then press the bearing out according to the SIR tool instructions.

I had to remove the inner bearing race from the hub because it got stuck on there (this is typical). I ended up using a Dremel tool with a cutting wheel to get it off. I made several vertical cuts around it and then used a chisel to give it the final whack. The inner race broke off no problem. But it did take a while.

Press bearing in and replace circlip. Easier said then done if you don’t have the right tool. I ended up creating a homemade tool using a couple of nails, pliers and taming it in with a flathead screw driver

Then just piece everything back together. You can press the ball joints back using another jack. Then tighten the nut.

Put the brakes on. Wheel on.

Done. Rollin’ smoove

Take the hub cap off

Ta-dah!

Axle nut in the middle. Found mine had no lock ring on it.

Keeping the car on the ground, I used a 30mm socket to loosen the axle nut. Put a pipe on the end of a torque wrench and it came off without a problem. I did put some penetrating oil in there first.

Loosen the 4 lug nuts on the wheel

Jack it up

Throw your wheel on a pile of wood

Getting’ there

Back of brake caliper

Disconnect the brake sensor behind the caliper

Loosen the 2 brake caliper bolts. You’ll need a 15mm wrench to hold the inner nut while loosening the outer bolt (17mm I believe).

Take the caliper off and hang it from the loop underneath the car (or some place else) with a short bungie cord or rope. Don’t let the brake line take the weight.

Grab a 19mm wrench and remove the two bolts that hold the caliper bracket

Remove the dust shield – 3 bolts (10mm wrench)

Get ready to remove the tie rod end and control arm ball joints – no biggie really, using the Harbor Freight ball joint separator. Took me a minute to figure out how to use it because it comes with no instructions, but it’s simple. You'll need to loosen the nuts on both ball joints so that they come to the tops of the bolts. Don't remove the nuts yet. Leave them on in order to protect the threads when using the tool. Then simply put the fork portion of the tool above the rubber boot and the single prong piece goes over the top of the bolt/nut. Crank down on the tool using a wrench (you'll see where it goes) and with each turn it’ll squeeeze that sucker out. The control arm ball joint separates with AUTHORITY. Damn – you’ll know it when it happens. Lol

At this point I removed the ABS sensor using an allen tool

Loosen the axle nut the rest of the way

I used a punch like this and a hammer to whack the axle out. Easier than I thought it would be.

I used the stoopid expensive SIR B90 tool to do the work. I don’t know. Maybe it’s worth it. It made the job easy work once I figured out the configuration of all the different parts of the tool. You have to use the tool 3 times for the job – removing the hub, removing the bearing and pressing the bearing.

Pressing out the hub config. Notice where the U-shaped part of the tool is pressing against the spindle. This part took me a minute to figure out.

Hub out. Remove the circlip and then press the bearing out according to the SIR tool instructions.

I had to remove the inner bearing race from the hub because it got stuck on there (this is typical). I ended up using a Dremel tool with a cutting wheel to get it off. I made several vertical cuts around it and then used a chisel to give it the final whack. The inner race broke off no problem. But it did take a while.

Press bearing in and replace circlip. Easier said then done if you don’t have the right tool. I ended up creating a homemade tool using a couple of nails, pliers and taming it in with a flathead screw driver

Then just piece everything back together. You can press the ball joints back using another jack. Then tighten the nut.

Put the brakes on. Wheel on.

Done. Rollin’ smoove

Comment