Project: Lela! (she loves it on all fours :) )

Collapse

X

-

you mean my D585 coils? I cut those out with a hacksaw. many, many hours of work. lol. no thanks :p

I have a CAD file if anyone wanted to have them cut out of plate though (waterjet, laser, CNC, whatever).

hella projectors are 100% glass, not acrylic, though I don't know the specific type of glass. I doubt if they're leaded glass, the ones I have were produced within the last 10 years, and lead is banned in most manufacturing these days. I disagree that a relay kit is necessary at all, the worst thing you could do is blow a fuse (which I've never had happen once), although this may depend on the quality of the ballasts. I do agree that an E30 projector isn't 100% perfect but it does work pretty dang well for being so old! certainly better than the #$^%# lifted 4x4 trucks with 8000k HIDs in reflector housings that are EVERYWHERE here. god damn those things piss me off!

I'll be switching to a projector retrofit kit pretty soon anyway so we'll see how much better it is. :)

I hear that.. This may be me being stiff and to the books on these as I always am. I agree they work just as well, I pertained my comment towards depo etc. As far as lead glass being produce, it's not banned here in MA anyway...I'm a glass geek. The company I work for (United lens) uses lead glass for all different types of applications. Mostly aero and military though. Osha requires certain manufacturing processes and handling procedures is all. Could you email me that file? I could have the guys down in the water jet department cut me up everything I need from aluminum stock. As for Your dist. Block off plate, you have a cad for that too? Send me anything you got with some info on the parts you used and where I can source them if you don't mind!

Maneshorin@gmail.comComment

-

I had one for the distributor cover but I lost it. however, I could re-make it again.

I'll post a link up to the coil bracket later today.Comment

-

Right! I feel this was about anything 6k and up.. It's ridiculous, and if anything THAT should be banned from production. Lol. But kids will be kids.I do agree that an E30 projector isn't 100% perfect but it does work pretty dang well for being so old! certainly better than the #$^%# lifted 4x4 trucks with 8000k HIDs in reflector housings that are EVERYWHERE here. god damn those things piss me off!

I'll be switching to a projector retrofit kit pretty soon anyway so we'll see how much better it is. :)Comment

-

Haha im totally with you on the HIDs :D Well, when i was 18 i thought 6-8000 looked so cool but naaah not anymore :PE30 325ix M50 turbo 7 spd DCT 4wd 840awhp @ 31 psi.

E30 M50 6 spd 764whp @ 24psi.

E30 M20 6 spd 675whp.Comment

-

Are the garagistic mounts urethane? If so, they're going to fail. Urethane the material is incompatible with the way it has to be loaded in making aftermarket BMW engine mounts. The harder you drive it and the more power you use, the sooner they'll come apart.

Just keep that in mind when you make things that will tie the engine down when the mounts fail. (You *did* keep the stock mount shells that protect against that failure mode, right?)Comment

-

those mount shells are for lateral loading and likely torque twisting. there's a reason they put them on the AWD cars. too bad the rubber bits are now NLA. :(Comment

-

Yes I retained the rubber isolators and the shells. I've never been one to trust the mounts would ever stay together. I have faith in the. Mounts.. I believe they used delrin. Not poly.. If it WAS poly, it's hard as a rock. Doesn't mean it won't fail. I did upgrade the bolt hardware they provided to some heavy grade stuff though.. I think I'm the setup should last me as long as I'd need it to ;) I also added a large top "washer" to help evenly distribute the load on the mount. I'll try getting a picture of what I mean.Comment

-

Few more pics of latest stuff

Brake res painted with viewable fluid level line on side

Heat shielded and bent the lines of the oil cooler off the manifold

Tidy routed oil feed and sleeved pressure sender tied away from heat.

Broken down alternator I'm rebuilding blasting and painting to match engine.

"Mila" being torn down for "project 800" (850 whp goal by summers end)

New box to handle all the extra work on the other side of the shop (box#3)

M20 cam gear in the mail

AKg subframe rebuild on deck.

-AN hose makeover, bilstein HD's going back in for now ; (

Can anyone tell me what rear valence this is? As soon as I find out I'll be trying to get one. Need to finish up the exterior, so I can rush her to the booth for some new skin!.. I have a limited window I'm 2 months to get her there... will I make it. ?!?!Comment

-

More progress pics.

Shortening the bump stops.

Cut!

Finally sorted out the grounding issue with the interior lights! Led upgrades, woo

Graves light dimmer module installed!

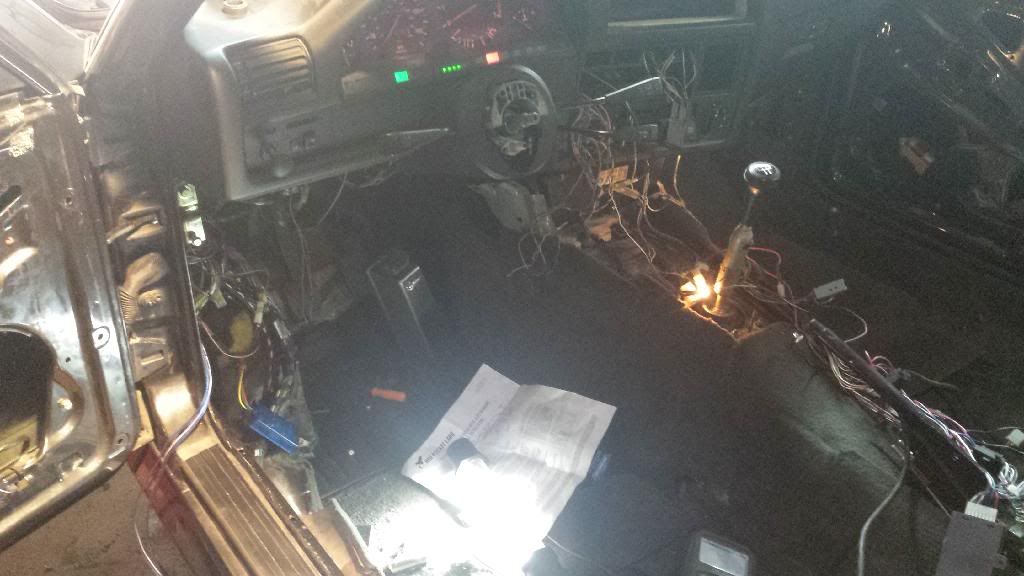

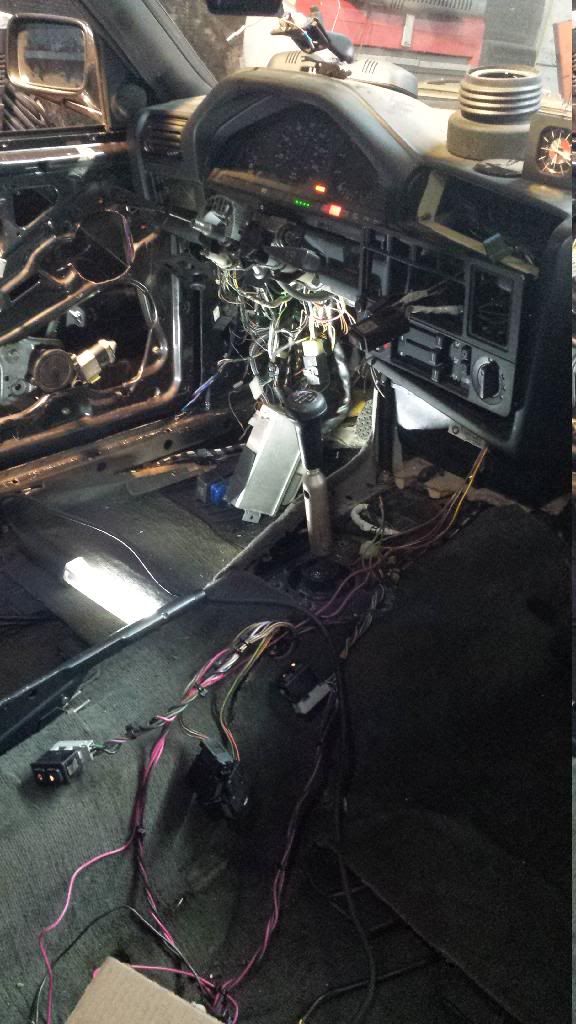

Tore apart the whole car to fix all the electrical problems

Crazy spaghetti mess..

Cleaned and tidy

Crossover done, wires tied tucked and cleaned. Everything electrical works! No dim lights, all indicators work, solid contacts and no more parasitic drain.

E36 window switches after I installed the one touch modules.

Illuminated now too

Door speakers cut and fit, cleaned up and put back together. Boston acoustics tweeters and midbass, hidden crossovers and wiring thru the rubber door grommets.

Another.

Got this little gem in the mail too!.

Thinking about this rear valence, anyone know what it is?

Thanks for looking. Keep on checking in daily, it will be all coming together rather quickly now.Comment

-

Thats for early cars - it wouldn't really fit the rear of an ix with the late style valance.Comment

-

I see.. I noticed the plastic bumper swap, and thought it'd be possible with alittle bit of modding I wasn't aware the rear metal valence itself would keep it from working... I want something clean.. I'm getting Into the bodywork phase of things, so I'm sorting through my possibilities.. I'll potentially be taking the skirts and flares off and widening the body itself, though I'm really addicted to the factory look of the flares as well. I'm stuck!.. somethings gonna pull through. I'm not looking to go over the top, but I am trying to steer a bit off from the usual. I'm trying to keep the theme for this car is OEM "plus"...Comment

-

It's too bad the gaps on the body lines in that picture, otherwise the same mtech wing I'm putting on is getting me real antsy to find something for the rear!.. my plan is to work from the back to front. It's a weird habit.. but getting the right valence in the rear will ultimately be the determining factor as to whether or not the skirts and flares stay. Suggestions ?Comment

-

-

Big old mess after my wiring frenzy.. lol

Finally put in my euro markers. Wired to stay lit during running, and switched ground so they will flash as indicators as well! Not too hard and better than solid state!

powers back on in the other half of my shop so I can finish sandblasting my strut tube and get the front suspension back together. So pumped! Will post pics tomorrow. Thanks for the support guys.. your comments and suggestions are always welcome.Comment

Comment