Hey guys,

I've had this idea floating in my mind for a long time..

Not that i dont like the AFM or something, but i do not like it , lol :devil:

So best way to replace it would be to use a MAP sensor.

You can't directly connect it, the Motronic wont understand it.

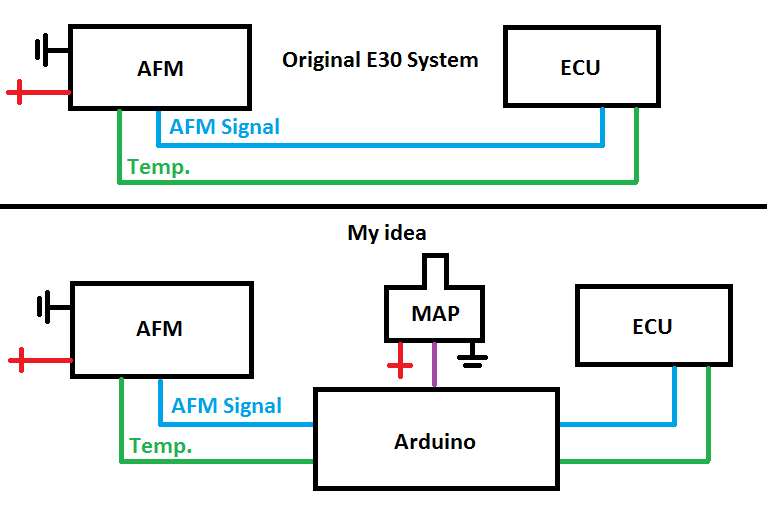

So my idea was to adopt the MAP sensor voltage to the corresponding AFM voltage, ie map the map ;D

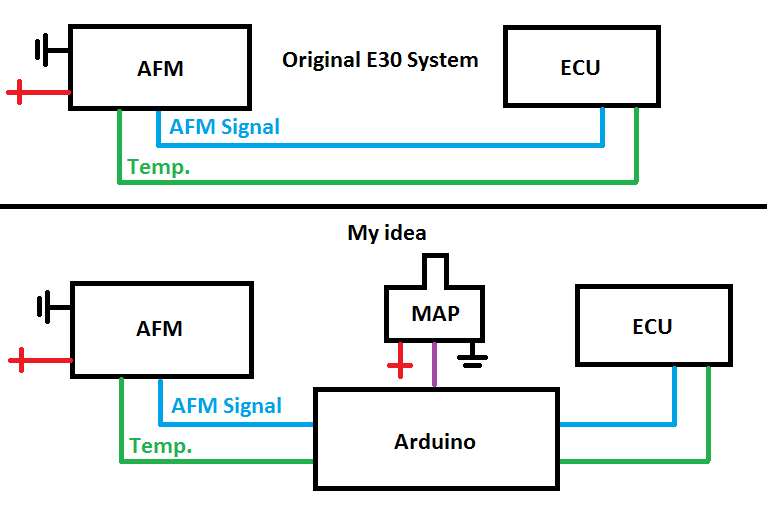

Basic scheme using Paint:

At first i would connect the MAP sensor and leave the AFM connected, and drive around just logging the voltage data to the Arduino, ie at this AFM voltage we have this MAP voltage, and at that AFM voltage we have that MAP voltage.

Basically just create a table of voltages across the whole 5v range.

After collecting data for a few days/weeks i would know the range and could just unhook the AFM and only keep the MAP and Temp sensor connected, and would just use the MAP for the voltage output to DME, since i would have all the voltage table.

This would act something like the UAFC from 14point7.

And it could also be setup to correct the voltage going to the DME to give you more/less fuel.

What are your thoughts on this?

Do you have any suggestions?

Thank you,

Max.

I've had this idea floating in my mind for a long time..

Not that i dont like the AFM or something, but i do not like it , lol :devil:

So best way to replace it would be to use a MAP sensor.

You can't directly connect it, the Motronic wont understand it.

So my idea was to adopt the MAP sensor voltage to the corresponding AFM voltage, ie map the map ;D

Basic scheme using Paint:

At first i would connect the MAP sensor and leave the AFM connected, and drive around just logging the voltage data to the Arduino, ie at this AFM voltage we have this MAP voltage, and at that AFM voltage we have that MAP voltage.

Basically just create a table of voltages across the whole 5v range.

After collecting data for a few days/weeks i would know the range and could just unhook the AFM and only keep the MAP and Temp sensor connected, and would just use the MAP for the voltage output to DME, since i would have all the voltage table.

This would act something like the UAFC from 14point7.

And it could also be setup to correct the voltage going to the DME to give you more/less fuel.

What are your thoughts on this?

Do you have any suggestions?

Thank you,

Max.

Comment