Thought I would update this thread since I am doing this again on my 85 323i. It's been a few years and all is well with the conversion on my M3. The shortened stock reducer hose has not split. Here are some pictures to show you what needs to be done.

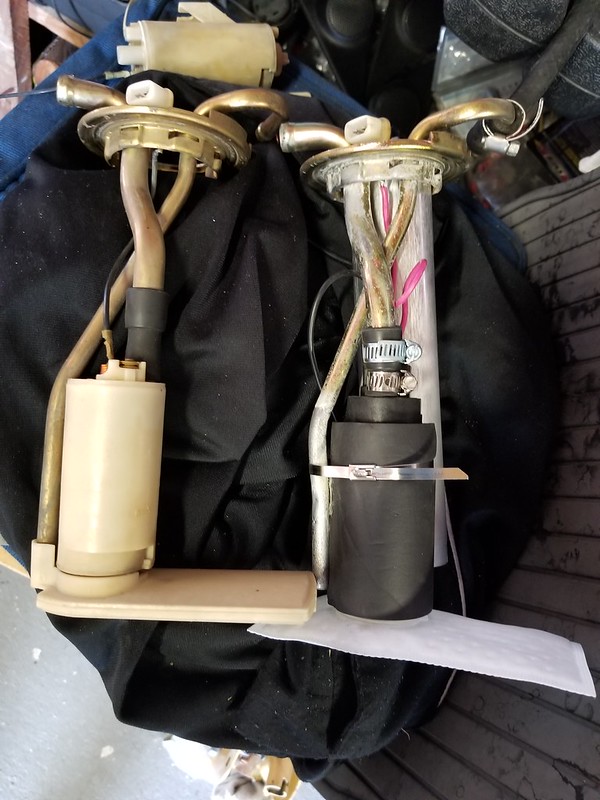

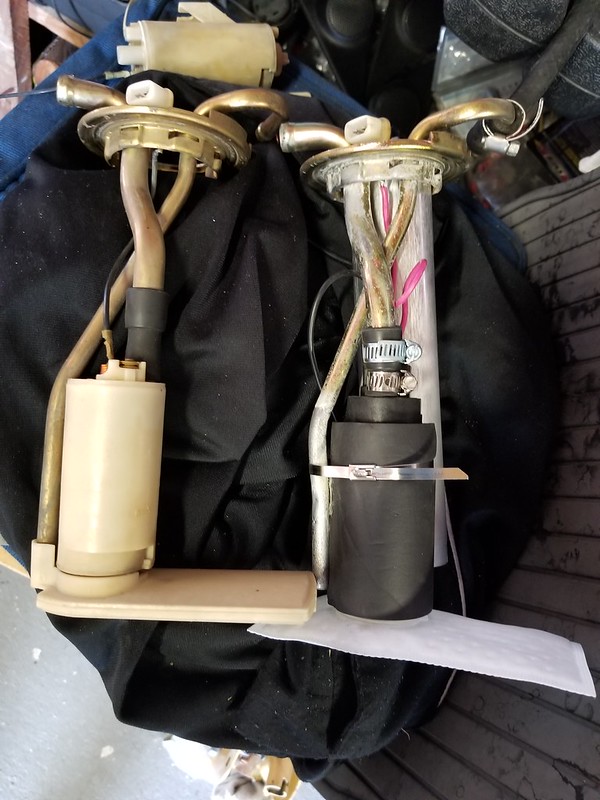

Note the size of the outlet on the brass holder vs the new TRE fuel pump.

I installed the TRE pump high enough to where the outlet is practically inside the brass tube and the connection is secured with the shortened reducer hose and clamps. The height also keeps the pick up in the ideal location. Make sure you orientate the filter at the proper angle and the level sensor clears the pump as well. For power, I desoldered the stock wiring and soldered the new wiring to the + terminal. For the ground, I chose to install a ring terminal on the ground wire and used the factory ground screw to ground the new pump. Here it is all assembled next to the original.

Note the size of the outlet on the brass holder vs the new TRE fuel pump.

I installed the TRE pump high enough to where the outlet is practically inside the brass tube and the connection is secured with the shortened reducer hose and clamps. The height also keeps the pick up in the ideal location. Make sure you orientate the filter at the proper angle and the level sensor clears the pump as well. For power, I desoldered the stock wiring and soldered the new wiring to the + terminal. For the ground, I chose to install a ring terminal on the ground wire and used the factory ground screw to ground the new pump. Here it is all assembled next to the original.

Comment