EDIT 8-Feb-2018: Dropbox link to project-related files and images.

General Info: https://www.dropbox.com/sh/70yvbe8f8..._Zt4JMGNa?dl=0

--------------------------

Continuing from the original / more general thread:

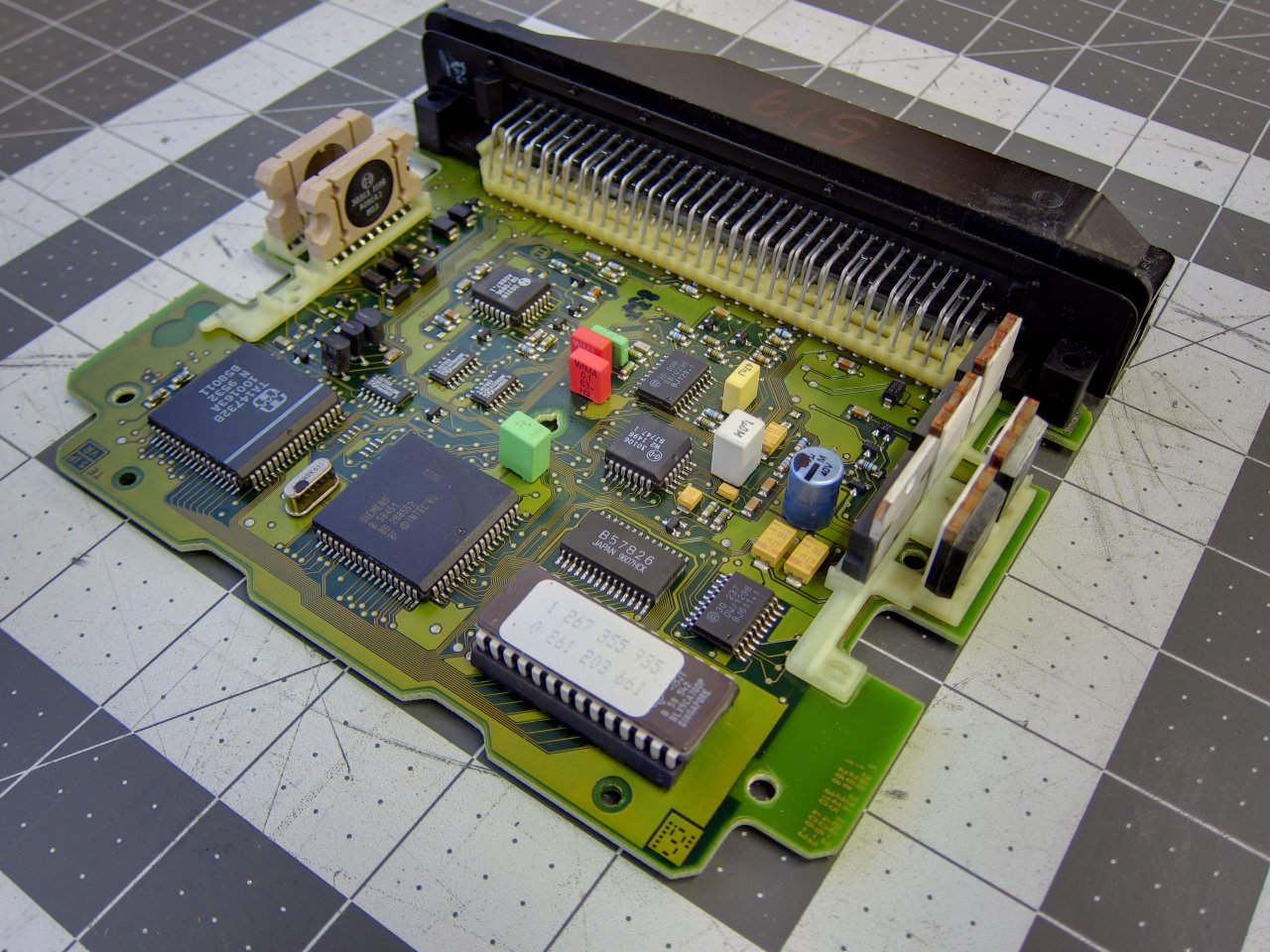

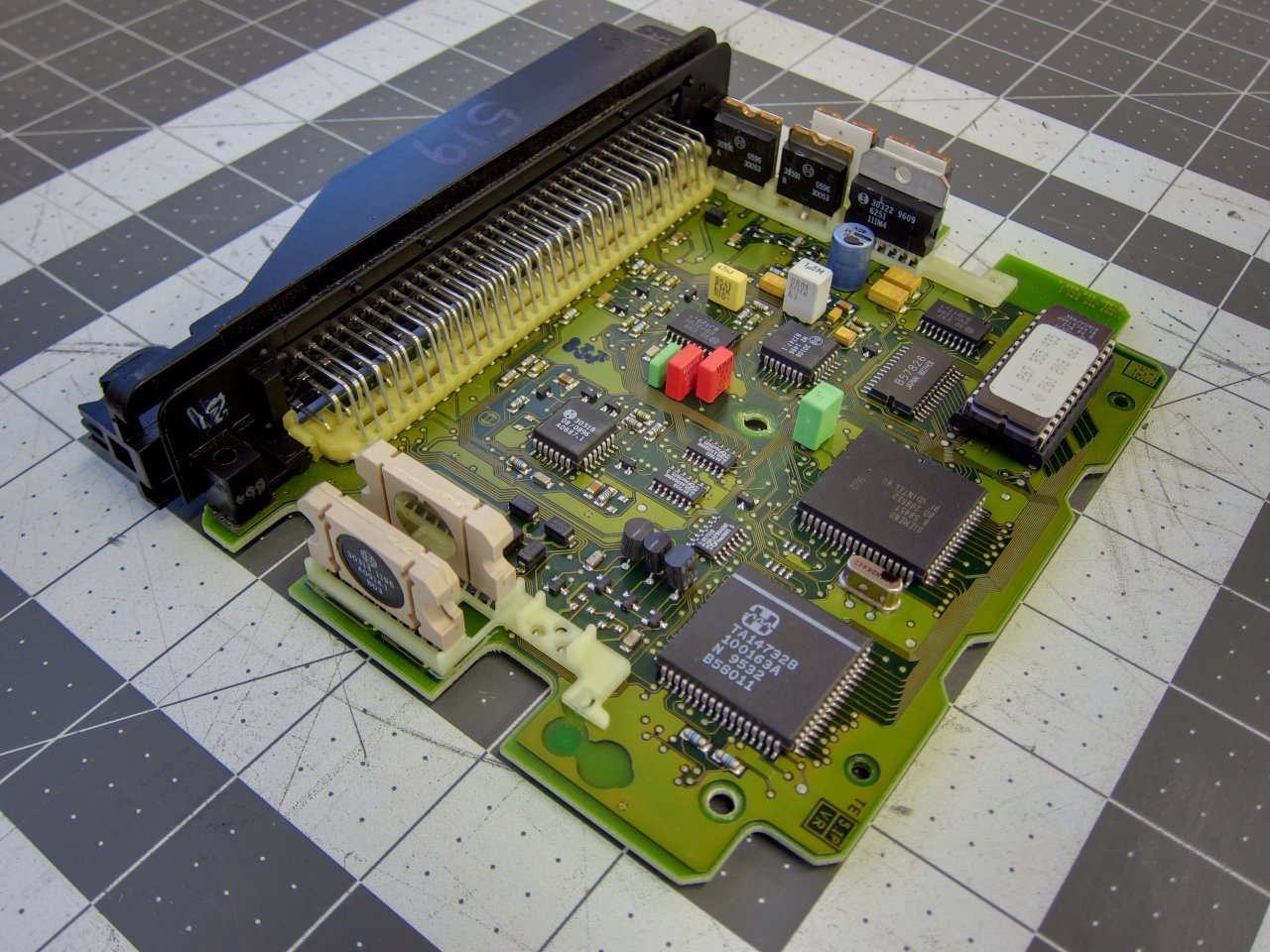

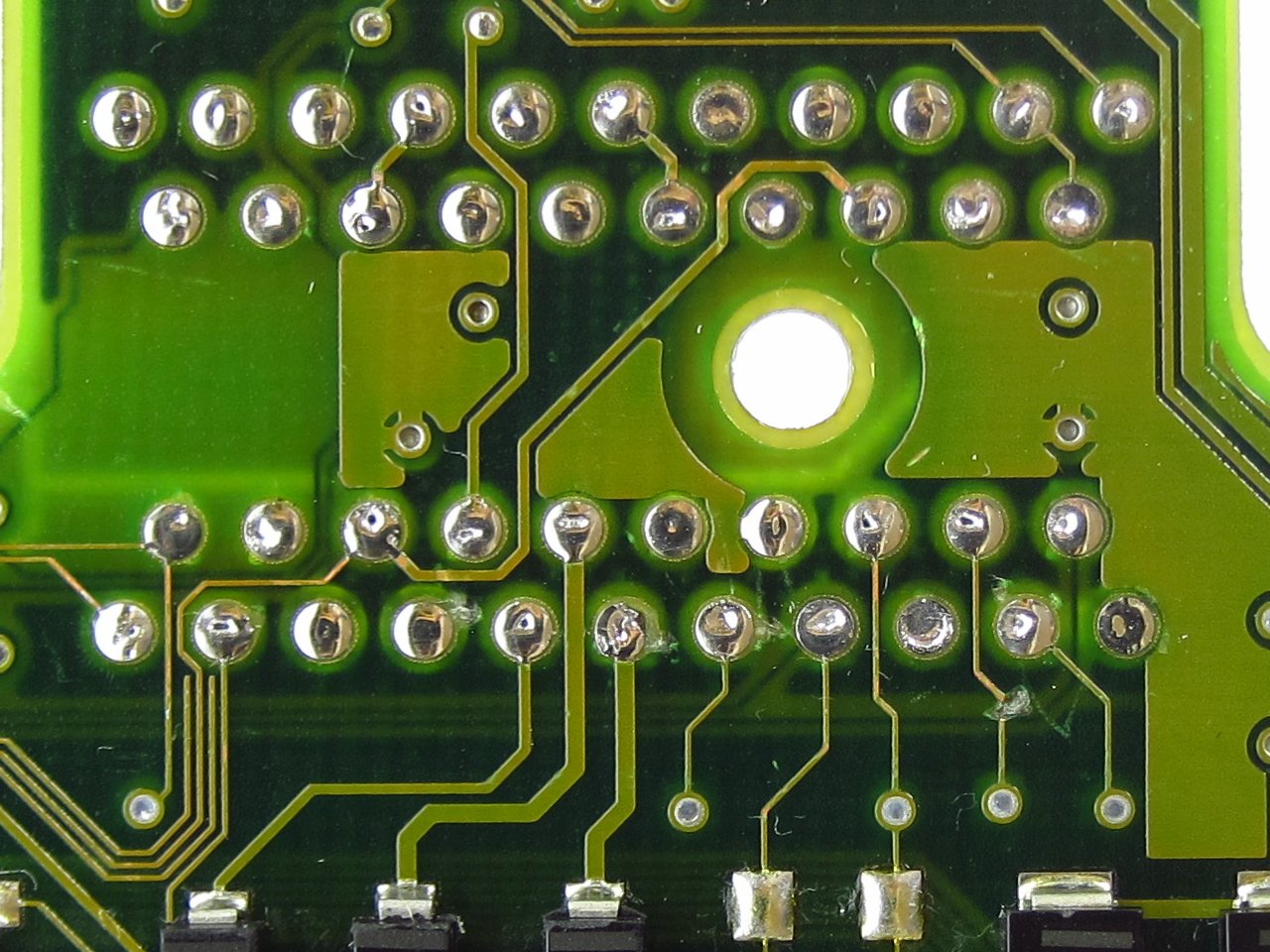

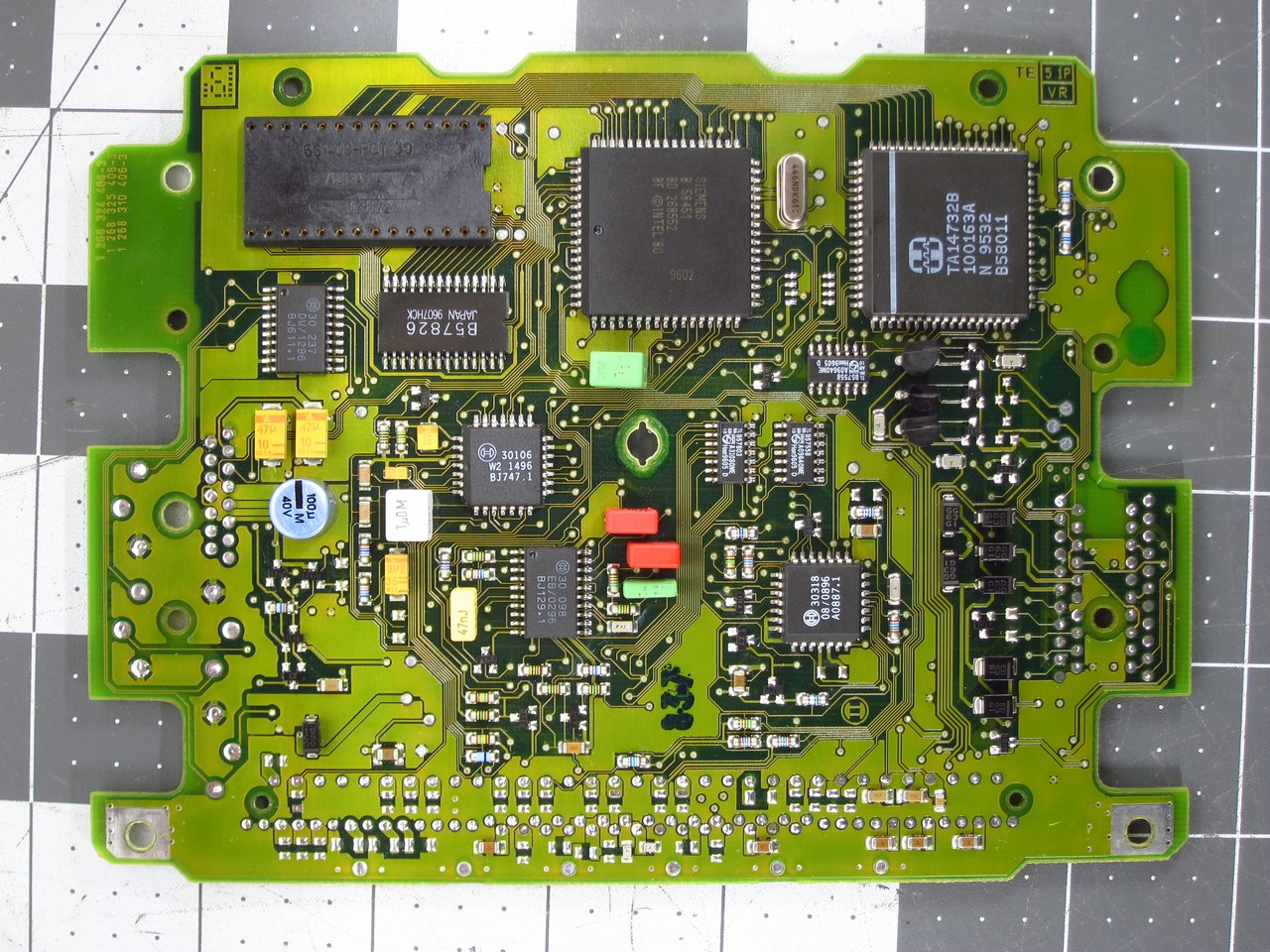

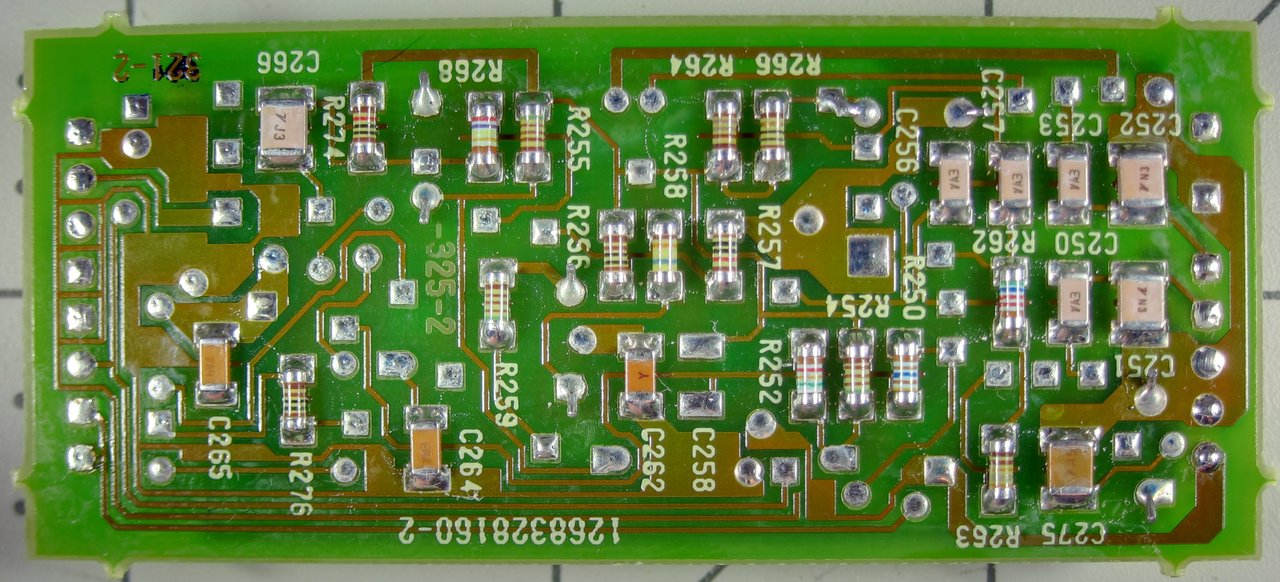

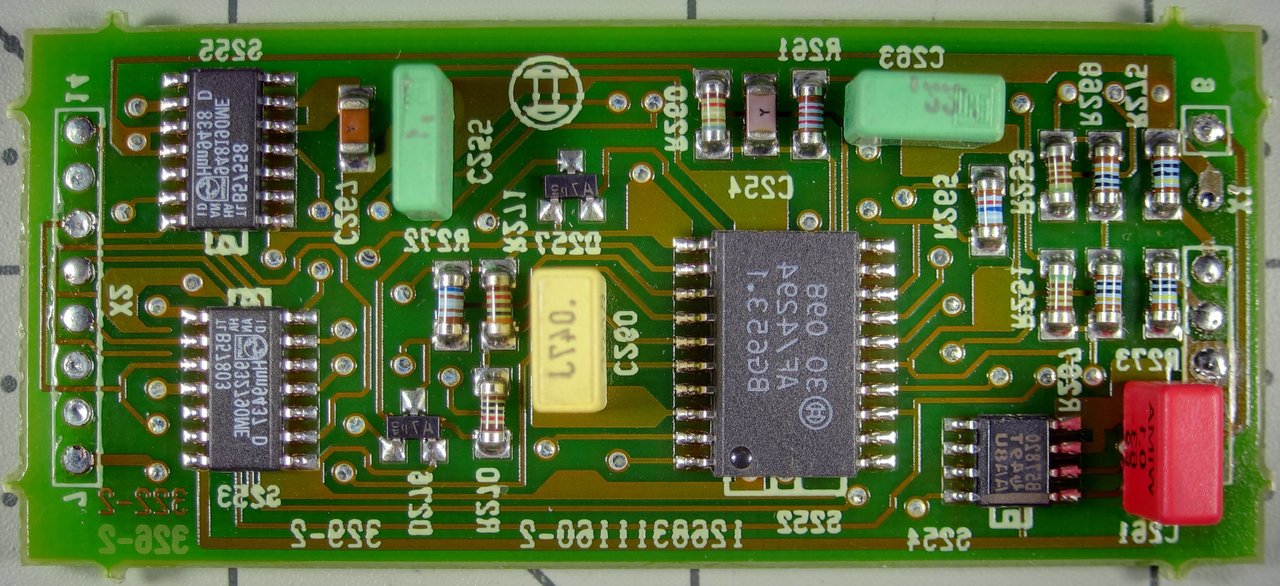

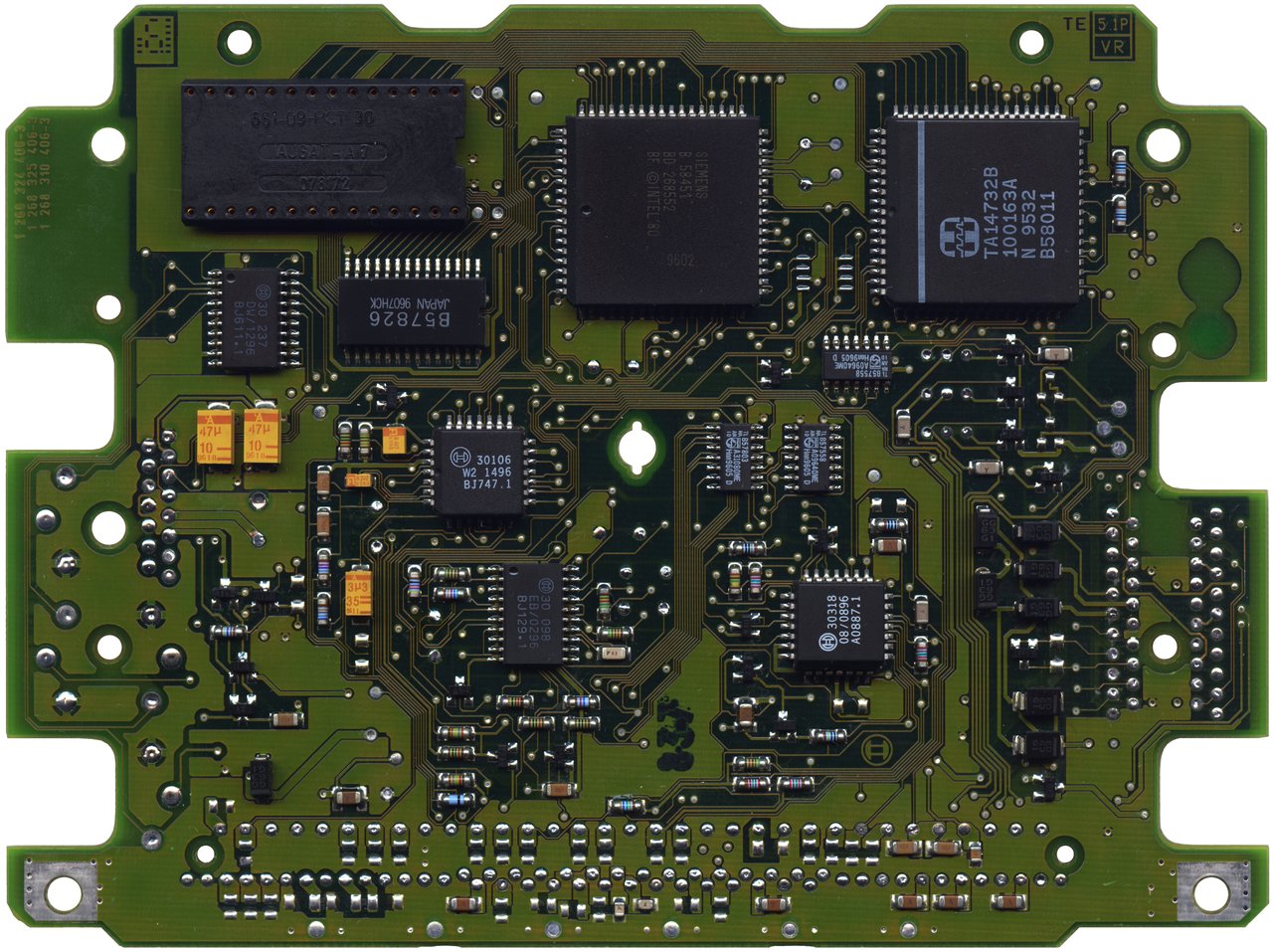

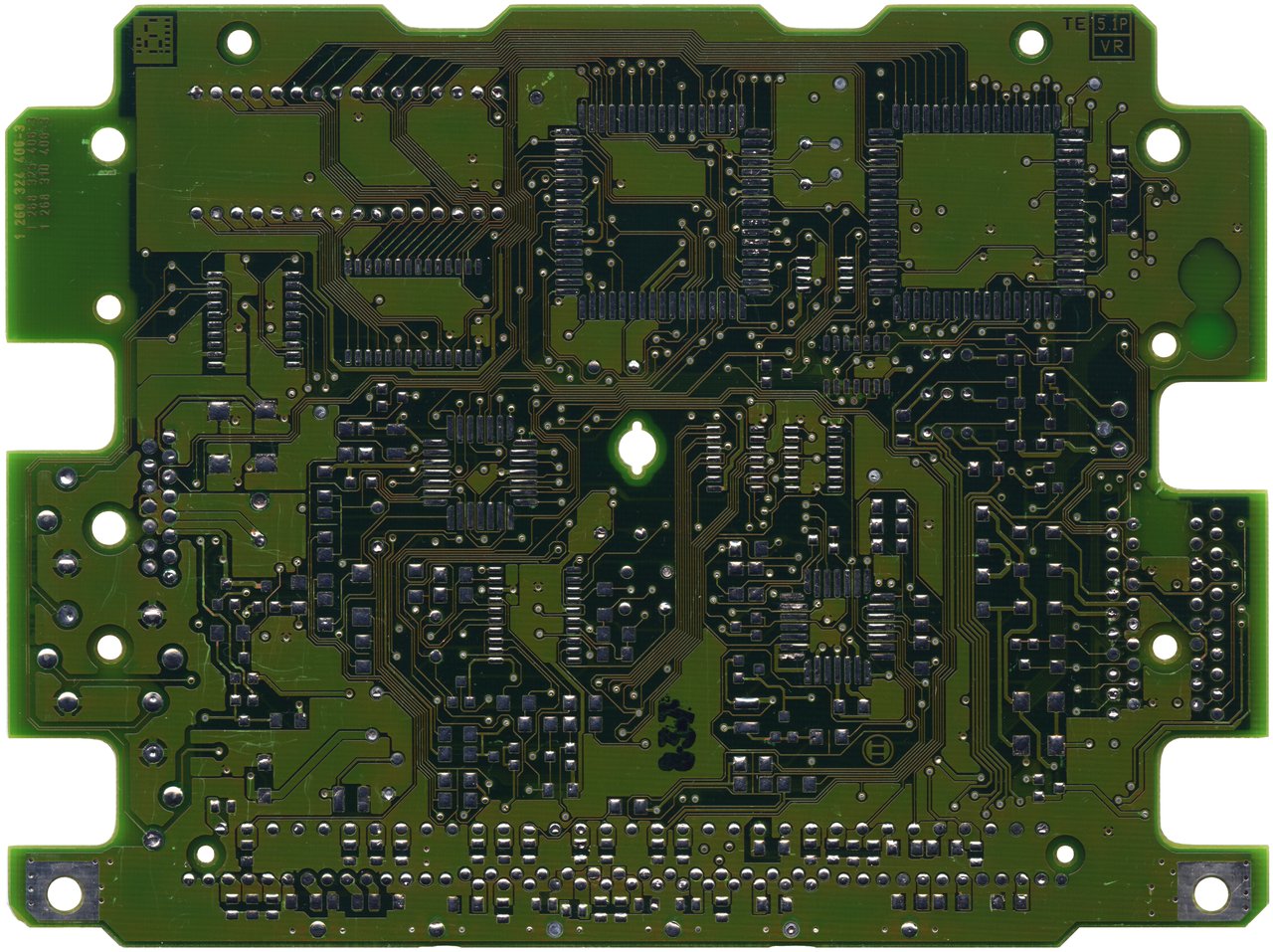

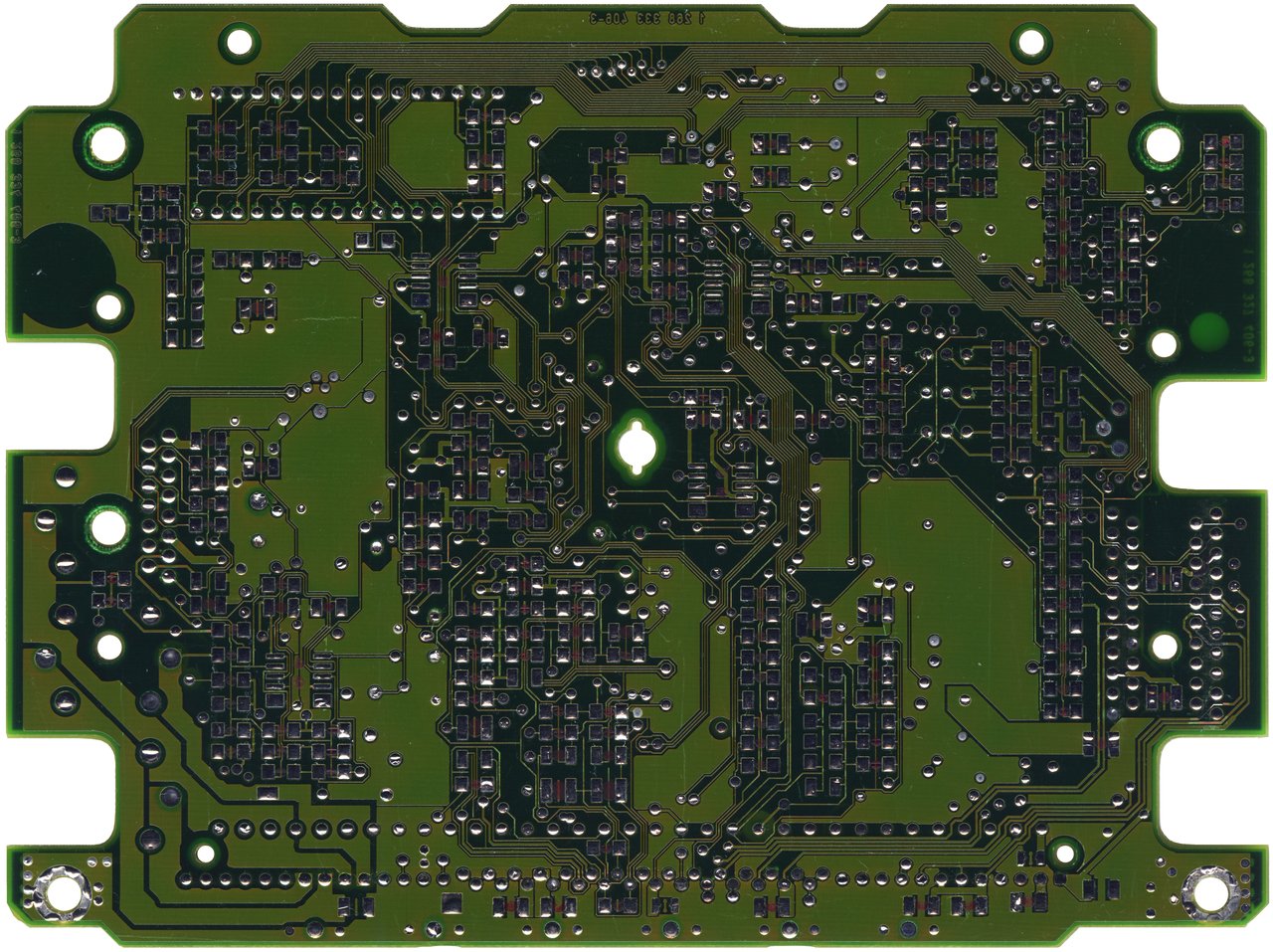

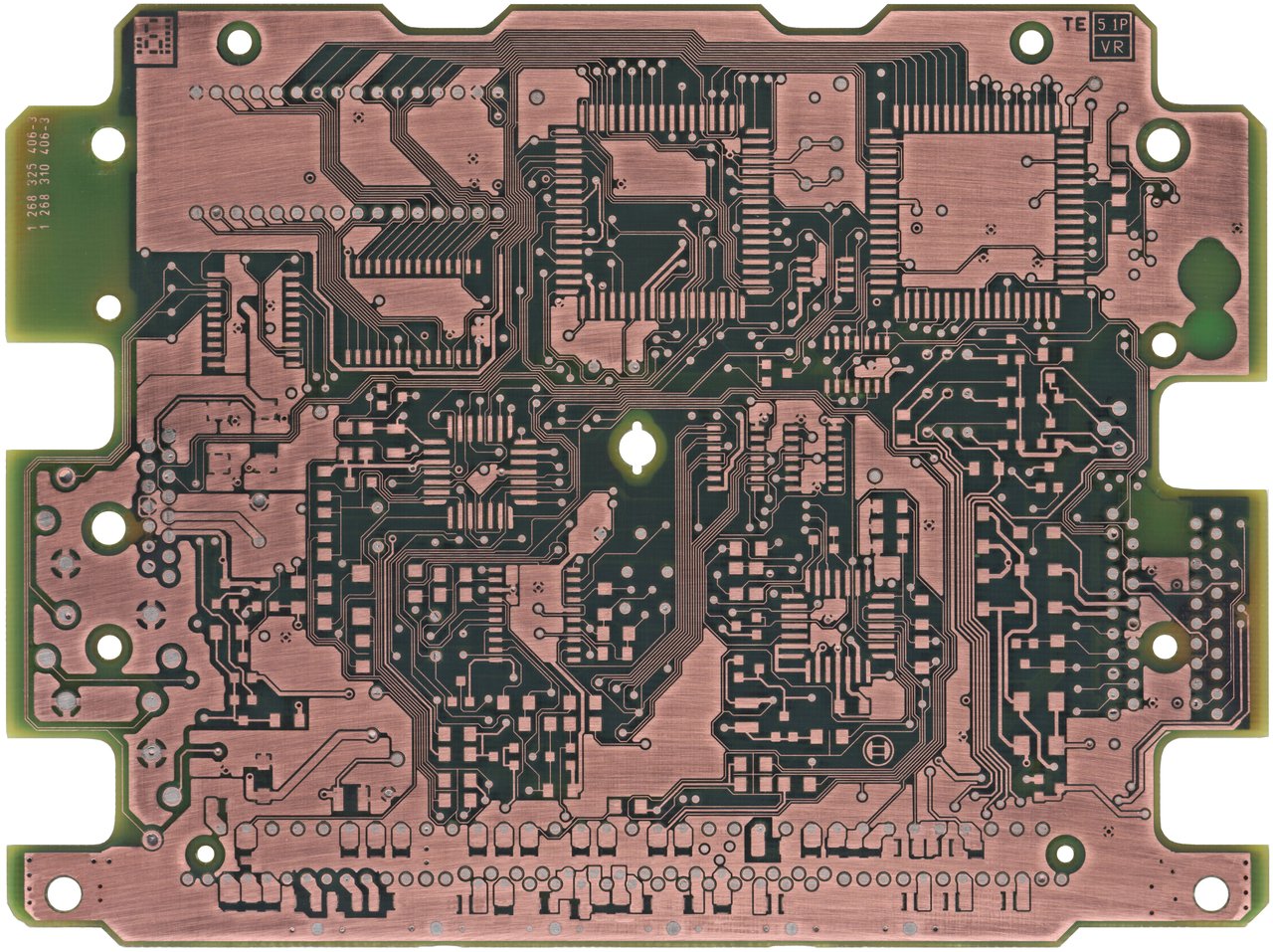

Since the previous thread dedicated to reverse engineering the M1.7 ECU is pretty long and somewhat specific to that system, this will be the information collection for stuff pertaining to M1.7.3. Many thanks to member Rasp for the hard work and assistance that has been provided, and more to come!

While I wait for my ECU units to arrive from eBay, I'm going to try to list the changes and modifications that will need to be made to the engine hardware, wiring harness and software.

1) Idle control valve. M1.7.3 can control the later stepper-style valve, which should allow for much better idle stability than the spring-door type that the E30 M42 uses with M1.7. There seem to be two ways to go here...install a full M44 throttle body, which I am 90% certain cannot work with my intake manifold (it may not fit between the stock E30 M42 manifold runners, and I have resonance caps welded on which make even less room. However, I can probably machine an adapter plate to hold the valve near the stock E30 location and include hose nipples for the stock hoses. It looks pretty easy from the pics.

https://www.ecstuning.com/b-bosch-pa...411435846~bos/

2) Knock sensors. The E30 M42 block has the mounting bosses for them, so I just need to get the sensors. Which sensors is an open question though. My engine has 87mm bores, and knock sensing frequency is mainly proportional to piston diameter it seems. The sensors themselves may have a wide enough bandwidth, or maybe not, so I will have to get some used ones from an E36 M42 and test their frequency response. Also, I am certain that I will need to make analog modifications to the knock sensing circuit in the ECU since it is probably a very narrow band-pass filter tuned to the stock piston diameter. I will find this out soon enough when I fully reverse engineer the M1.7.3 ECU hardware though.

3) Fuel injection. The stock E30 M42 wiring harness only has 2 wires going to the ECU for the injectors, firing them in pairs. M1.7.3 has 4 individual outputs, which are fired in pairs. My thought for now is to keep the factory 2-wire setup and install internal jumpers so that the driving transistors are still "sharing" the load.

4) Coolant temp (CLT) sensor. Should be able to keep the stock one and simply modify the linearization maps.

5) IAT. Should be the same deal as the CLT sensor.

6) MAF. Right now I have a stand-alone converter box which exactly mimics the stock VAM functionality using a VW MAF sensor. I can either stick with this and adjust the VAM transfer function in the software, or if the software can be modified to handle the MAF signal (very fast, large voltage swings at open throttle) I would love to do that.

7) Wide-Band O2 sensing. For now this is just a "wish to have." I can keep using the narrow-band simulated output for a while until everything else works. Also, at least in M1.7, it seems that the O2 heater relay is turned off at full throttle, which was a problem for my wide-band system, so I jumped the relay to be always-on whenever the fuel pump relay was is active. With M1.7.3 I would prefer to have a working O2 relay so I suppose I can make sure that it is never disabled when the engine is running.

8) EGS / ASC / EWS / DISA systems to be disabled in software since they do not apply here.

9) M1.7.3 Pin 56...is this a separate 12V input for powering the ignition subsystems? It is labeled as "Ignition, Terminal 15" / "Ignition Lock" in the wiring diagrams.

10) Dual temperature switch. I will need to check to see if the E30 coolant witch functions the same way. Also I do not even have AC installed and the aux electric fan is not present, so maybe I will see about disabling anything related to this in software.

OK, quite a list there. Priority #1 is going to be full reverse engineering of the M1.7.3 unit since that is needed to better understand things. The software is even more important to this of course, but I have less experience there, and there are some other helpful people here who know all about it. This will not be a quick overnight project!

Link:

E36 M43 wiring diagrams: http://www.e30tuner.com/assist/m173r...ngDiagrams.pdf

General Info: https://www.dropbox.com/sh/70yvbe8f8..._Zt4JMGNa?dl=0

--------------------------

Continuing from the original / more general thread:

Since the previous thread dedicated to reverse engineering the M1.7 ECU is pretty long and somewhat specific to that system, this will be the information collection for stuff pertaining to M1.7.3. Many thanks to member Rasp for the hard work and assistance that has been provided, and more to come!

While I wait for my ECU units to arrive from eBay, I'm going to try to list the changes and modifications that will need to be made to the engine hardware, wiring harness and software.

1) Idle control valve. M1.7.3 can control the later stepper-style valve, which should allow for much better idle stability than the spring-door type that the E30 M42 uses with M1.7. There seem to be two ways to go here...install a full M44 throttle body, which I am 90% certain cannot work with my intake manifold (it may not fit between the stock E30 M42 manifold runners, and I have resonance caps welded on which make even less room. However, I can probably machine an adapter plate to hold the valve near the stock E30 location and include hose nipples for the stock hoses. It looks pretty easy from the pics.

https://www.ecstuning.com/b-bosch-pa...411435846~bos/

2) Knock sensors. The E30 M42 block has the mounting bosses for them, so I just need to get the sensors. Which sensors is an open question though. My engine has 87mm bores, and knock sensing frequency is mainly proportional to piston diameter it seems. The sensors themselves may have a wide enough bandwidth, or maybe not, so I will have to get some used ones from an E36 M42 and test their frequency response. Also, I am certain that I will need to make analog modifications to the knock sensing circuit in the ECU since it is probably a very narrow band-pass filter tuned to the stock piston diameter. I will find this out soon enough when I fully reverse engineer the M1.7.3 ECU hardware though.

3) Fuel injection. The stock E30 M42 wiring harness only has 2 wires going to the ECU for the injectors, firing them in pairs. M1.7.3 has 4 individual outputs, which are fired in pairs. My thought for now is to keep the factory 2-wire setup and install internal jumpers so that the driving transistors are still "sharing" the load.

4) Coolant temp (CLT) sensor. Should be able to keep the stock one and simply modify the linearization maps.

5) IAT. Should be the same deal as the CLT sensor.

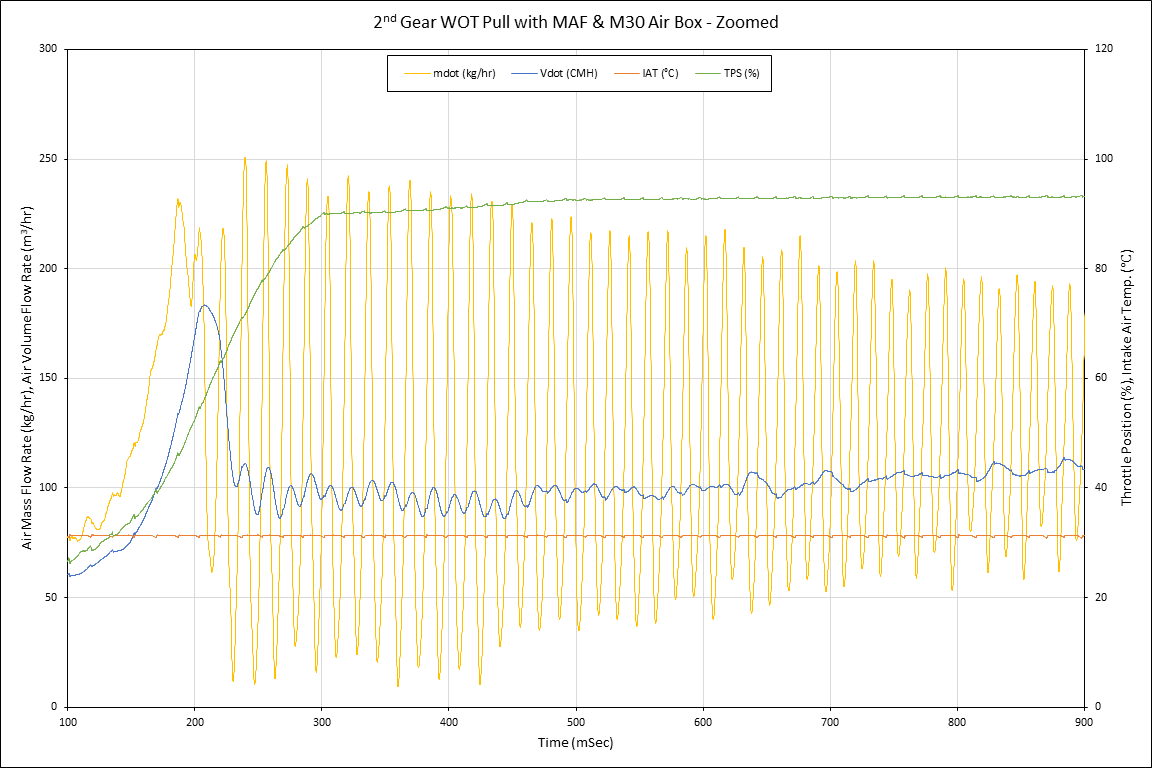

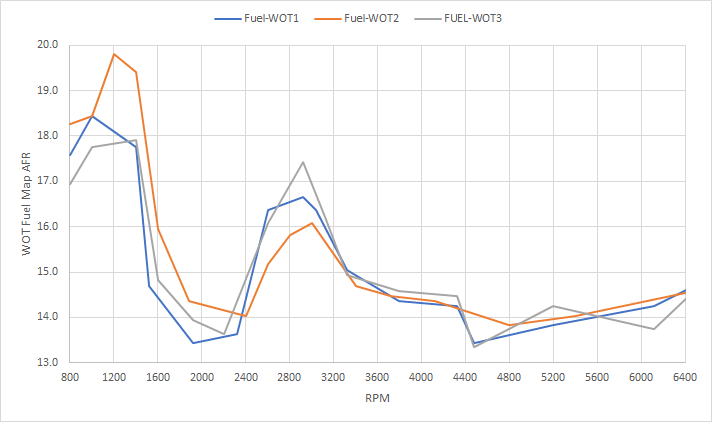

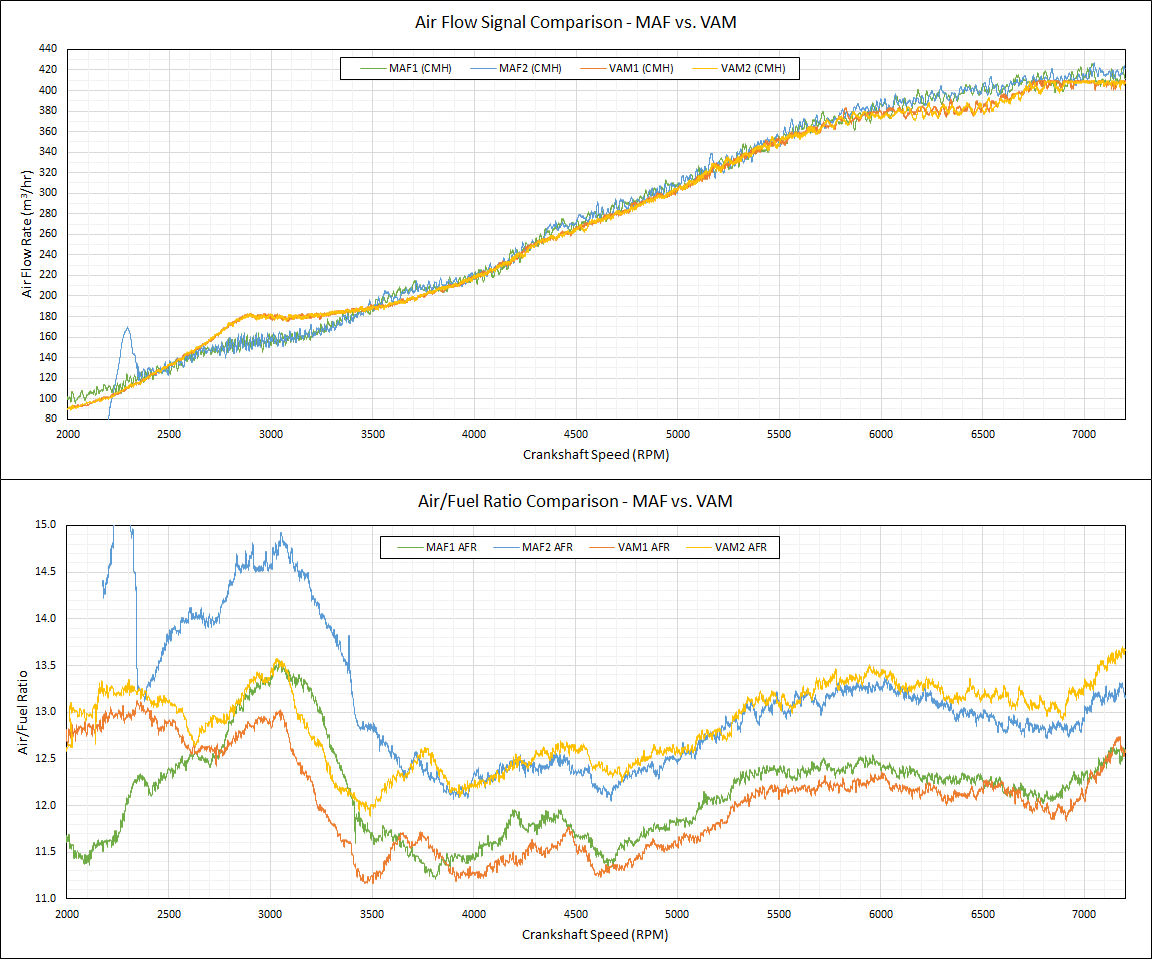

6) MAF. Right now I have a stand-alone converter box which exactly mimics the stock VAM functionality using a VW MAF sensor. I can either stick with this and adjust the VAM transfer function in the software, or if the software can be modified to handle the MAF signal (very fast, large voltage swings at open throttle) I would love to do that.

7) Wide-Band O2 sensing. For now this is just a "wish to have." I can keep using the narrow-band simulated output for a while until everything else works. Also, at least in M1.7, it seems that the O2 heater relay is turned off at full throttle, which was a problem for my wide-band system, so I jumped the relay to be always-on whenever the fuel pump relay was is active. With M1.7.3 I would prefer to have a working O2 relay so I suppose I can make sure that it is never disabled when the engine is running.

8) EGS / ASC / EWS / DISA systems to be disabled in software since they do not apply here.

9) M1.7.3 Pin 56...is this a separate 12V input for powering the ignition subsystems? It is labeled as "Ignition, Terminal 15" / "Ignition Lock" in the wiring diagrams.

10) Dual temperature switch. I will need to check to see if the E30 coolant witch functions the same way. Also I do not even have AC installed and the aux electric fan is not present, so maybe I will see about disabling anything related to this in software.

OK, quite a list there. Priority #1 is going to be full reverse engineering of the M1.7.3 unit since that is needed to better understand things. The software is even more important to this of course, but I have less experience there, and there are some other helpful people here who know all about it. This will not be a quick overnight project!

Link:

E36 M43 wiring diagrams: http://www.e30tuner.com/assist/m173r...ngDiagrams.pdf

Comment