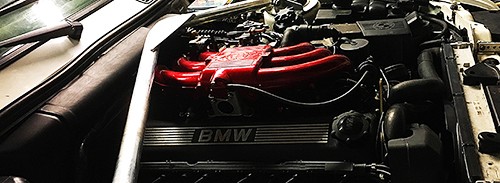

I actually purchased the manifold off good and tights manifold group buy and it is beautiful!

I actually purchased the manifold off good and tights manifold group buy and it is beautiful!

Ruthless the turbo 325ix

Collapse

X

-

-

Alright guys I know it has been a couple months with no update. I have been pretty busy with life I got a new job and moved to a different city and haven't had time to work on my car. I got everything sorted out and now have time to work on it again. Here are some updates.

I got my crank in, I plastigauged it and it was well within specs with the new bearings.

I cleaned my pistons best I could which was a major pain in the ass. Dishwasher actually worked good hah

I installed my pistons and plastigauged the rod bearing and they we're also in spec so that was nice.

I started working on my head and getting my valves phased. Needed some help from a friend but after that the retainers where pretty easy.

Phasing

valves in.

Sent from my E6653 using TapatalkLast edited by CrazyPrime; 01-11-2016, 08:26 PM.Comment

-

I checked the valves for leaks by putting them in the compression stroke and poured fuel in the dome. They didn't leak a bit.

Head fully assembled

I put my head studs in and was wondering if a small amount of threads sticking up was normal or if will effect anything.

I am going the MLS route and was ready to throw the head on after cleaning the surfaces meticulously. After trying to put the gasket on it was getting caught on the dowels around the two head studs. I ripped them out and ordered a couple more along with some other parts. Here is it sitting on the block if you notice the right top side isn't flush.

Sent from my E6653 using TapatalkComment

-

Comment

-

Make sure you take the all rivits out but one on the MLS and coat each layer with the correct spray or it will leak. I i forget exactly what i used on muh mls but do a Google search you should be able to find what I mean.Comment

-

What brand of MLS did you get? Mine says not to use copper spray. why take the rights out?

Sent from my E6653 using TapatalkComment

-

Its a cometic mls. Most people online say it's not necessary and some even say don't do it like you said. I did it because my engine builder recommend it and he highly regarded builder for racing motors. I believe it's more less to help the individual stamped sheets line up perfectly rather then accually promoting the adhesive of it. The way I did it was I removed all the rivits but one corner rivit then spread each layer out and sprayed a light coating on each layer. After it tacked up I lined them back up and put it on and torqued the head down. It's worked great for me and I got no leaks. I originally heard a lot of horror stories about mls gaskets leaking and I asked my builder about doing orings by hand and he said it was be nearly impossible to get it completely even and perfect(I realized a lot of people do it this way and it works for them but this is what I was told) he recommended me to go with a mls and said I can spray it if I was worried about it leaking. It worked good for me, I would recommend calling a few engine builders and see what they do on there turbo engines.

Best of luck, and build looks great so far!Comment

-

sigpic

Rebellion Forge Custom Fabrication

1988 325is - TrackRat in progress

Instagram @rebellionforgeComment

-

Cool build. What's your CR going to be?Comment

-

Future tip, oven cleaner works well to clean piston tops. Let it sit for 10-15 minutes, stiff nylon brush if you want to work it around before wiping it off. A few times like that should produce clean Pistons tops.Comment

-

Comment

-

Comment

-

I wont tell your wife about the dishwasher if you don't tell mine, lol. :-PComment

-

Since our pans hang so low and are susceptible to breaking, you'd only have to worry about replacing the pan if it happens rather than welding on a new fitting for your drain. It's also always going to be above oil level.

Here's where I put mine - no problems for the past year.

Wish I went AN though.

Comment

Comment