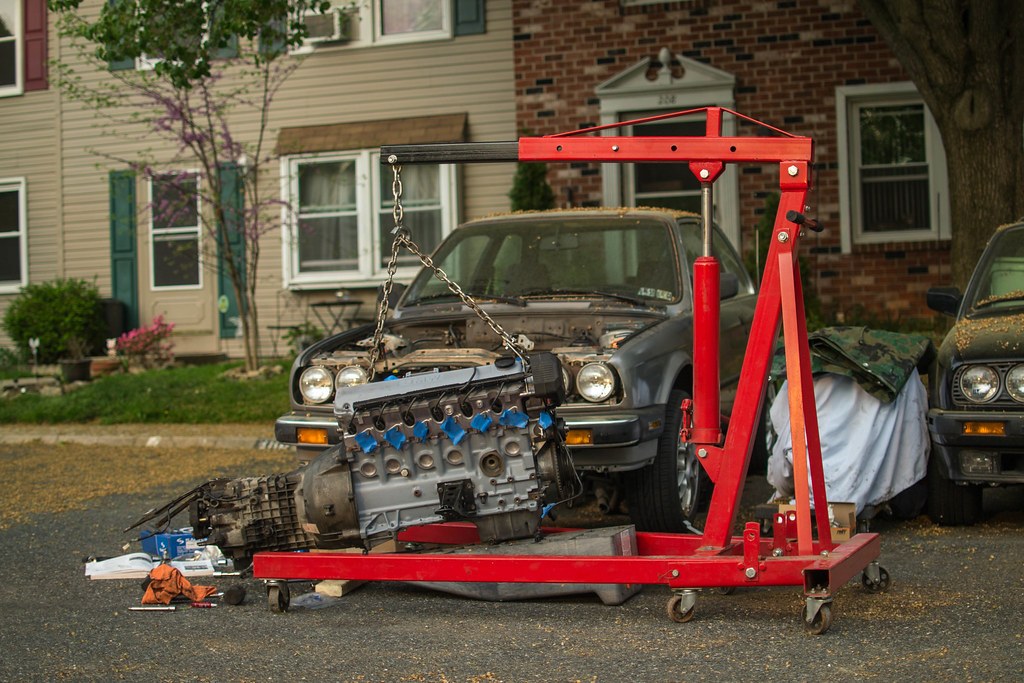

Hey R3v, I just wanted to take the time to recap how my stroker m20 build went. I had a lot of help from forum members and a few shops so I want to put down how my process went incase anyone in the future is searching for information. I will say this is the particular way I went about it with zero engine building knowledge/experience beforehand, so I'm sure there are other paths available that could have even made more sense.

The build changed directions multiple times and the budget got tossed out after awhile. The engine is not complete to the point I want it as of now but it is leak free and drivable so I consider it to be at a good point. Most of this is scattered in my "members ride" thread incase you've already checked that out.

The specs are

Bottom End (VAC Motorsports)

M20B25 bored +1mm

M52 84mm stroke crank

M20B25 stock 135mm rods

Custom Carrillo Pistons 85mm 11:1 compression ratio

Top End (Bimmerheads)

885 Head Port and Polish

284 Cam

Stock Valve

OEM Dual Springs

HD Rockers

Others

Pink Top Injectors 21#

Megasquirt 2 (Whodwho)

Cold Air Intake (Kamotors)

Nuke Adjustable Cam gear

BavAuto Headers

Vibrant Bottle Style Resonator and Muffler using 2.5" piping

RHD 7lb Flywheel

Back in the end of September? 2014 I picked up the engine from BimmerBuddies in PA and with the help of my dad got it home and started disassembling it at a friends shop. No plan here, just take it apart and get it ready to go to VAC. In retrospect I wish I would have been more particular and precise about bagging bolts and organizing everything that came off. Reassembly was made difficult due to trying to rush this process.

The crank bolt was a pain to get off. Pry bar and block of wood wedged in to stop the crank from spinning and a long breaker bar being jumped on was the final trick to loosen it up.

I was able to take the bottom end to VAC on black Friday and lucked into a discount deal they were running. Originally I was only going for 10:1 CR but they convinced me to go 11:1 since I was using a standalone ECU to tune fuel and spark with it. Nothing wrong with a little extra compression. Now it was getting to be winter and I was slowly gathering parts needed for the swap.

Fast forward to February I was getting ready to pick up the bottom end stuff from VAC. They were a little slower than I initially thought but I wasn't saving money as fast as I thought for other parts so it didn't really put me behind. They had a problem with a secondary bearing oil drive something (I don't remember what it was) and that was partially the lag on their end. I was able to find a used set of BavAuto headers which was number 1 on the potential exhaust list for me. I decided to go with Bimmerheads for the head instead of VAC because of the price and I wasn't blown away by VAC although I got to tour their shop which was cool. Knowing Bimmerheads is a big part of the community I was glad with my decision.

Once the head came in I figured I had the majority of the large parts and it was just gasket and maintenance type items left to get.

Engine assembly coming in post 2.

The build changed directions multiple times and the budget got tossed out after awhile. The engine is not complete to the point I want it as of now but it is leak free and drivable so I consider it to be at a good point. Most of this is scattered in my "members ride" thread incase you've already checked that out.

The specs are

Bottom End (VAC Motorsports)

M20B25 bored +1mm

M52 84mm stroke crank

M20B25 stock 135mm rods

Custom Carrillo Pistons 85mm 11:1 compression ratio

Top End (Bimmerheads)

885 Head Port and Polish

284 Cam

Stock Valve

OEM Dual Springs

HD Rockers

Others

Pink Top Injectors 21#

Megasquirt 2 (Whodwho)

Cold Air Intake (Kamotors)

Nuke Adjustable Cam gear

BavAuto Headers

Vibrant Bottle Style Resonator and Muffler using 2.5" piping

RHD 7lb Flywheel

Back in the end of September? 2014 I picked up the engine from BimmerBuddies in PA and with the help of my dad got it home and started disassembling it at a friends shop. No plan here, just take it apart and get it ready to go to VAC. In retrospect I wish I would have been more particular and precise about bagging bolts and organizing everything that came off. Reassembly was made difficult due to trying to rush this process.

The crank bolt was a pain to get off. Pry bar and block of wood wedged in to stop the crank from spinning and a long breaker bar being jumped on was the final trick to loosen it up.

I was able to take the bottom end to VAC on black Friday and lucked into a discount deal they were running. Originally I was only going for 10:1 CR but they convinced me to go 11:1 since I was using a standalone ECU to tune fuel and spark with it. Nothing wrong with a little extra compression. Now it was getting to be winter and I was slowly gathering parts needed for the swap.

Fast forward to February I was getting ready to pick up the bottom end stuff from VAC. They were a little slower than I initially thought but I wasn't saving money as fast as I thought for other parts so it didn't really put me behind. They had a problem with a secondary bearing oil drive something (I don't remember what it was) and that was partially the lag on their end. I was able to find a used set of BavAuto headers which was number 1 on the potential exhaust list for me. I decided to go with Bimmerheads for the head instead of VAC because of the price and I wasn't blown away by VAC although I got to tour their shop which was cool. Knowing Bimmerheads is a big part of the community I was glad with my decision.

Once the head came in I figured I had the majority of the large parts and it was just gasket and maintenance type items left to get.

Engine assembly coming in post 2.

Comment