Some background: I've been having some overheating problems. After ten to fifteen minutes of running it would start to nudge over half then eventually keep heating up. Twice last week it got to between 3/4 and red line and was there for a few minutes (maybe 5) before I could get off the road.

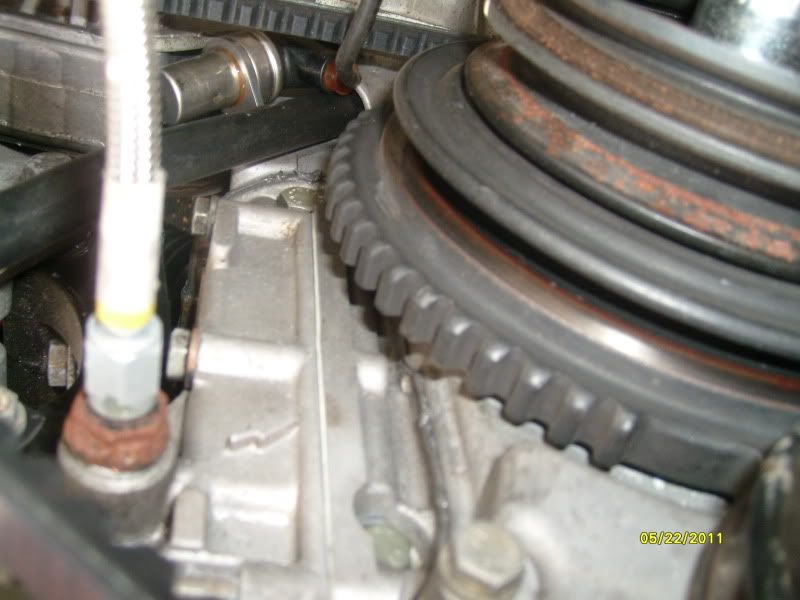

I needed a timing refresh anyway so I planned to replace water pump and thermostat in the hopes that one of those was the cause of my problem. So I just finished that job and now I cant get it to start.

Description of symptoms: when I try to start I can hear to starter, it sounds like its trying to turn over, then an abrupt 'clunk' and a visible jolt in the engine.

I've given up for tonight, but I need to make sure that plugs and coils are all plugged back in in the proper order. I can turn the crank by hand, which I hope means that its not hydro locked, which is the number one thing I'm afraid of given the history of overheating.

Any other ideas of what could be causing this problem? Steps I could have done wrong or missed in reassembling the engine? Simple solutions, like a sensor wire or something?

Please help. Thanks

I needed a timing refresh anyway so I planned to replace water pump and thermostat in the hopes that one of those was the cause of my problem. So I just finished that job and now I cant get it to start.

Description of symptoms: when I try to start I can hear to starter, it sounds like its trying to turn over, then an abrupt 'clunk' and a visible jolt in the engine.

I've given up for tonight, but I need to make sure that plugs and coils are all plugged back in in the proper order. I can turn the crank by hand, which I hope means that its not hydro locked, which is the number one thing I'm afraid of given the history of overheating.

Any other ideas of what could be causing this problem? Steps I could have done wrong or missed in reassembling the engine? Simple solutions, like a sensor wire or something?

Please help. Thanks

Comment