Working on it. I got the stuff installed back in the car today, but the RPM measurement is giving me some trouble. It seems like there is a lot of noise getting in to the signal, as well as some sensitivity issues. I have asked the guy that made the VR sensor conditioner board for some help with that. It would be even better if I could find the RPM pulse signal on the Motronic itself (the nice 5V square wave one that I am sure exists in there lol).

It is going to be hard to make an actual comparison of air flow between the two air meters (AFM & MAF). Based on the test logs I took, I think that the fact that they differ in age by 2 decades, and the fact that I have not made calibration curves for each specific sensor, is going to mean that no direct air flow comparisons can be made. According to the log, the MAF flows ~20CFM less than the AFM, which I imagine is really just due to the tolerance son the sensors (the data sheets seem to indicate that there can be up to +/- 5% accuracy variance between sensor units).

So, I will try to do a comparison where I measure the time it takes to go from 2000RPM to 7700RPM in 2nd gear at WOT with both sensors on the same day on the same section of road.

Random Data Plots - M42 Engine Parameters Stock vs 2.1L Stroker

Collapse

X

-

You da man bmwman!

We all want to see data plots and the MAF mod finally coming to fruition!Leave a comment:

-

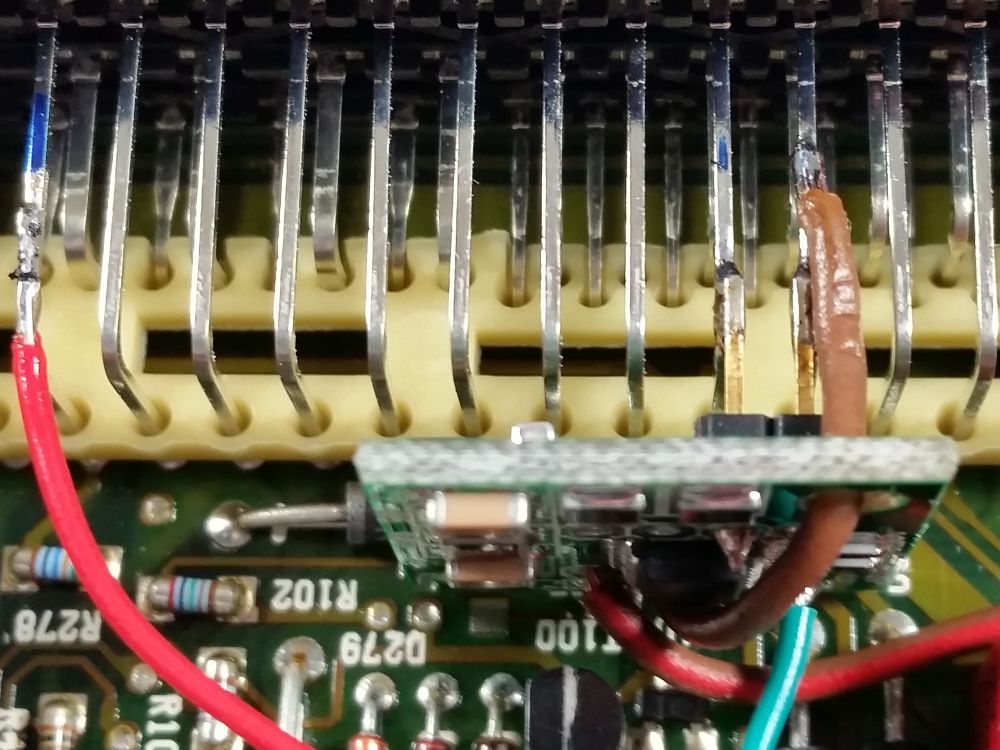

Prepare your butts. I am hacking up my Motronic board for everyone's amusement (mainly my own). Since I was getting a bit of ignition EMI noise on the previous logs, I decided that the 8ft run of cable from under the hood to my glove compartment might have something to do with it. So, I figured that I would keep things as short as possible and tap right into the ECU to "see what it is seeing".

The little "extra" PCB is a VR sensor conditioner that is popular with Megasquirt users. It will also work nicely here I think. Since the crank signal is prone to noise (it is one of the few sensor signals that the stock harness puts a shield over), I connected the conditioner directly onto the input pins in the Motronic.

Anywho, I should have things buttoned up and working in a day or two. The plan thereafter is to run some logs with the MAF and then repeat the AFM logs. It feels like there might be a slight "flat spot" in the 2500-3000RPM powerband with the MAF+M30 air box, so hopefully the logs will help me to get a handle on what is up. Also, hopefully they will show some sort of benefit to using the MAF at all lol.Leave a comment:

-

Yep, that was you. I don't know if I ever responded to your email, but at least with the timing tables I'm using, 114 degree offset was a major improvement, with better fuel economy, more off-power boost, a stronger idle, and lower EGTs. I also made the changes you suggested for idle stability, and that helped as well.Leave a comment:

-

That was probably me. I'm running 114°, falling edge. I verified that setting with a timing light and fixed advance, FWIW.I'll have to check my settings in the tune, but I was running 122 degree trigger angle in Megasquirt, which corresponds to 20th tooth falling edge based on the math (123 degrees, actually) but at the behest of another member, I actually went with 114 degrees and picked up a bunch of power - that's like adding 8 degrees of advance - with no knocking or pinging. I can't remember what edge I'm triggering on though... Definitely curious what others are using as well. If I still had a flywheel with a TDC pin, this would be a lot easier to check.Leave a comment:

-

Cool, thanks. I have been looking for more info on how VR sensors work in applications like Bosch Motronic setups. It sounds like the positive-to-negative zero-crossing point of the VR signal occurs at the middle of the tooth, not the falling-edge of the tooth. That actually makes more sense now that I think about how a VR sensor works.

Can anyone provide a photo of the front of the engine with the crank set to TDC (the notched tooth aligned with the mark on the oil filter housing)? I'd really like to see how everything aligns in terms of the teeth and the crank VR sensor. The photo would probably need to be of an M42 outside of the car, or maybe from in the engine may with the radiator and stuff removed (a real straight-on shot).

Here are some fun links with good reading on VR sensors:

EFI, Fuel Injection, Auto, automotive, car, TPI, computation, ECU, MegaSquirt, GPIO, MicroSquirt, Sequencer, stim, MegaShift, MShift, DIY, transmission, 4L60E, 4L80E, controller, shifter

EFI, Fuel Injection, Auto, automotive, car, TPI, computation, ECU, MegaSquirt, GPIO, MicroSquirt, Sequencer, stim, MegaShift, MShift, DIY, transmission, 4L60E, 4L80E, controller, shifter

EFI, Fuel Injection, Auto, automotive, car, TPI, computation, ECU, MegaSquirt, GPIO, MicroSquirt, Sequencer, stim, MegaShift, MShift, DIY, transmission, 4L60E, 4L80E, controller, shifter

EFI, Fuel Injection, Auto, automotive, car, TPI, computation, ECU, MegaSquirt, GPIO, MicroSquirt, Sequencer, stim, MegaShift, MShift, DIY, transmission, 4L60E, 4L80E, controller, shifter

DIYAutoTune Hall effect sensors for crank or cam triggers. Specs, wiring, and setup details for both tabbed mount and red body threaded versions.

DIYAutoTune Hall effect sensors for crank or cam triggers. Specs, wiring, and setup details for both tabbed mount and red body threaded versions.

Last edited by bmwman91; 06-18-2015, 08:28 PM.Leave a comment:

-

I'll have to check my settings in the tune, but I was running 122 degree trigger angle in Megasquirt, which corresponds to 20th tooth falling edge based on the math (123 degrees, actually) but at the behest of another member, I actually went with 114 degrees and picked up a bunch of power - that's like adding 8 degrees of advance - with no knocking or pinging. I can't remember what edge I'm triggering on though... Definitely curious what others are using as well. If I still had a flywheel with a TDC pin, this would be a lot easier to check.Leave a comment:

-

Nice, thanks for the confirmation. This thing is already a ton of fun as it is, so if there is a bit more power to e squeezed out I am all for it!

I am also thinking of adding crank position as one of the outputs since I basically have all the info I need for it by measuring RPM (I am using the stock VR crank sensor & 60-2 wheel). Can anyone confirm if the 2 items below are true?

1) Cylinder 1 TDC aligns with the falling-edge of the 20th tooth after the double-gap.

2) The pin on exhaust sprocket that triggers the cam position sensor roughly aligns with cylinder 1 TDC.

While there is nothing too super useful about crank position, I just want to see how that lines up with the MAF output at WOT since the MAF can basically resolve individual intake pulses traveling up the intake track. It also allows me to measure ignition advance if I want to add that in the future.Leave a comment:

-

It is true about the chips. While you can get really close, the best tunes are done on a dyno. I have tuned 2 OBD1 s52's recently. Both cammed, both with headers, same sized injectors, both 3.5" MAF etc. Plugging in the tune from car "A" was much better than their off the shelf chip for car "B". Both cars benefited greatly from a dyno tune (both made much more power with a live tune), but goes to show how accurate that statement is. Car "A" also made about 20whp more than the more recent one.Leave a comment:

-

That would be a very interesting comparison on the dyno. Definitely staying tuned!Leave a comment:

-

When I get my car on the dyno I will definitely post up dyno data (and a video if I remember to take one lol). The plan is actually to get on a dyno with the stock AFM, do some pulls, then swap the MAF on and repeat. From there I will then have a custom tune made. MM provided a custom chip to go with their engine (based on a tune for this engine design but not this specific engine), but from what people have told me, no two engines are identical so I can probably benefit from some additional tuning. The MAF conversion should be dialed in to the point that zero tuning is needed if I swap between that and the AFM, but since I am pretty sure that the MAF will be less restrictive on this engine I want to be tuned for any additional air flow.Leave a comment:

-

I am also very interested in seeing how the MM 2100 engine performs on the dyno. If you get a chance to get it on the dyno, would you be able to get a video of it too Will?Leave a comment:

-

I would love to see a MM engine on the dyno. One would think with all the claims on the website, there would be actual data to go with it.Getting to 180bhp is not all that hard, just expensive. IMO, running a MAF is the hard part because there is nothing plug-n-play out on the market for the M42.

You don't need solid lifters either. I am running Metric Mechanic's "205bhp" 2.1L M42 and it just uses lighter weight hydraulic lifters. I put the power number in quotes because I need to get on a dyno and actually see what it can do.Leave a comment:

-

Before I installed my turbo, I installed a wideband to see what the stock computer was commanding. Granted, I had a MarkD chip in it, but it was running very close to 13.5:1 almost regardless of conditions. WOT was a tad richer, more like 13:1.Leave a comment:

-

Getting to 180bhp is not all that hard, just expensive. IMO, running a MAF is the hard part because there is nothing plug-n-play out on the market for the M42.Interesting to see how lean it runs throughout a WOT pull, I wonder how the AFR plot of a stock 318 looks. To get an M42 to 180hp NA, I think an AFM bottleneck would be the least of your worries. What does it need? Solid lifters, custom cams, porting, big valves, new intake manifold, new exhaust, higher compression... I'd probably go with ITBs if I was doing an NA build.

You don't need solid lifters either. I am running Metric Mechanic's "205bhp" 2.1L M42 and it just uses lighter weight hydraulic lifters. I put the power number in quotes because I need to get on a dyno and actually see what it can do.Leave a comment:

Leave a comment: