M42 Head Gasket Blown, Project Thread

Collapse

X

-

yeah new gaskets, seals, bearings and a re-ring job if pistons are ok. fingers crossed the valve contact pinched a ring and you get a freebie set of slugs..lolLeave a comment:

-

Of course, avoiding the up-sell is part of much of life. I just want the product that I expected in the first place, and that's what was agreed to. In terms of all the other non-MM improvements, I won't bother mentioning that stuff to them. While they do want to stand behind their product, they don't need any encouragement to try to sell their version of that stuff lol. I'll do my best to avoid a "you told me so" outcome, and this wasn't really in my budget planning anyway, which I also expressed to MM to make it clear that I am not in a position to blindly toss money at the situation.Leave a comment:

-

you know they will try and sell you stuff and still and convince you not to go down other routes lolLeave a comment:

-

So Jim from MM called me earlier. I guess it bugged him that the engine is out on its ass again. Despite repeated mechanical issues with the expensive product I purchased, I have maintained a good working relationship with them. I expressed to Jim that I don't really feel like I ever ended up with the product I paid for, even if the last HG install involved my own errors, and MM would like to try to make things right for good.

The short story is that I am pulling the engine and shipping it out to them. They'll tear it down, and I'll make the call about what to do or not from there. They aren't doing it for free, but it is at a reduced cost that I think is fair. This is somewhat of a "lazy" solution, but I just don't have sufficient time and energy to deal with this correctly myself right now. If MM was not willing to work out a deal then I might feel more motivated since I dislike the idea of throwing money at things, but they seem willing to stand behind their product.

Also, outsourcing the work gives me time to look into the other stuff that we have been discussing, such as an RHD flywheel, improved header and cams.Leave a comment:

-

honestly pull the head and make an assessment before going "full bore" with rebuild. you can pull the pan off and rods out in the car if neededLeave a comment:

-

Bores are 87mm. The head gasket is an OEM M44 +0.3mm thickness one, which I believe has ~85mm holes.

Given some of the obvious abuse that occurred, I am heavily leaning towards a complete tear-down to make sure that everything in the bottom-end is in proper shape. I am going to need to locate a competent local builder, or maybe see what it would cost me to work with MM and spend a week out there observing and learning. If I am going to go with Cometic, I'll probably need to get the block into a shop one way or another to properly check the surface and (possibly) machine it. At that point I am probably taking the bottom end apart anyway.Leave a comment:

-

What bore size are you running, 86 or 87 and are you use a stock head gasket?

the reason for asking is on the m20 the stock head gasket approx 85.5 mm ID overhangs the bore 86 mm (MM pistons are chamfered to clear) so the fire ring is exposed to more heat among other things which is not ideal. now MM use 87 mm bores but a different piston (flat style) but not sure what gasket they use. i imagine with M42 the gasket also overhangs the bore

I also agree a MLS is probably worth considering for the following reasons:

- for the thinner gap between bores the MLS is stronger and can tolerate a less than ideal tune better, most OE use them these days so they are pretty good certainly need to be more meticulous though.

- optimum piston to head clearance, you want the piston to head clearance (approx 1 mm) to generate good squish which if the gasket overhangs the bore is probably not happening. With a cometic MLS there are about 10 thicknesses you can get to set it up correctly with the piston close to the head but need to check P to V. looking at the pistons you should not have an issue though as pockets look deep enough for a hot street cam with 2-2.5mm lift at TDC.

You can visually see if the bores are totally stuffed but not much more. Having a cross hatch is one thing but the characteristics of it and how much is left are in the microscopic scale. With the piston down the hole you could use a bore gauge to check but you’d want to know what it was at the start otherwise you might not learn much.

You can do a leak down after the head gasket goes on before assembling the cam and whole thing to evaluate the ringsLeave a comment:

-

[2013 content]

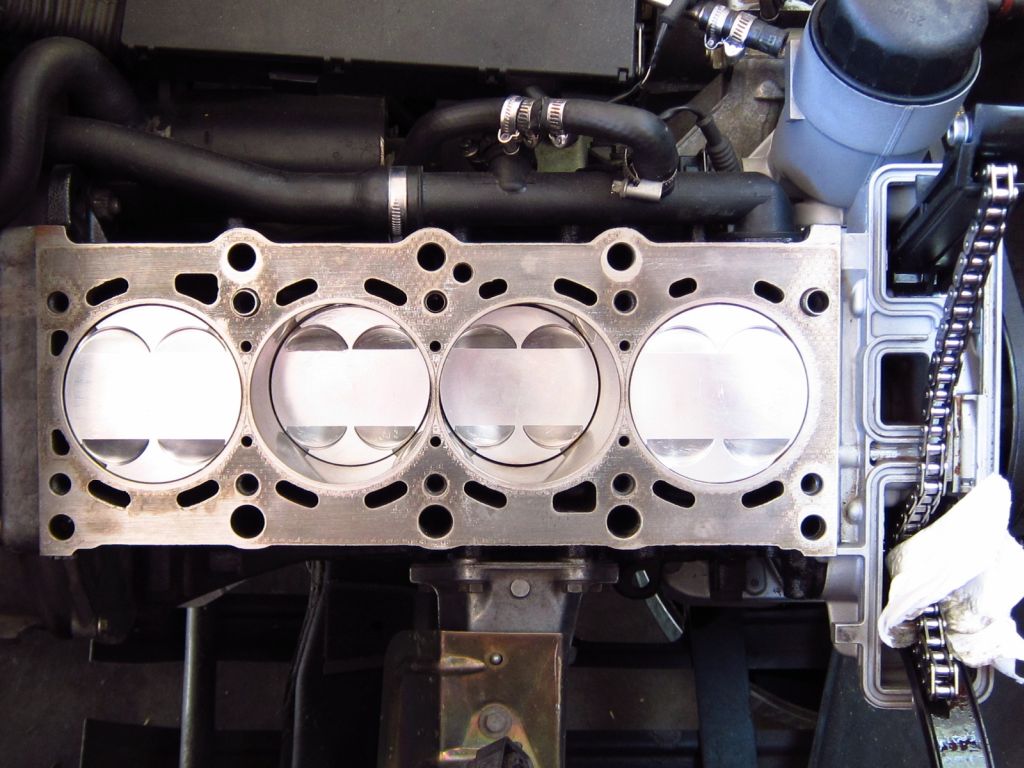

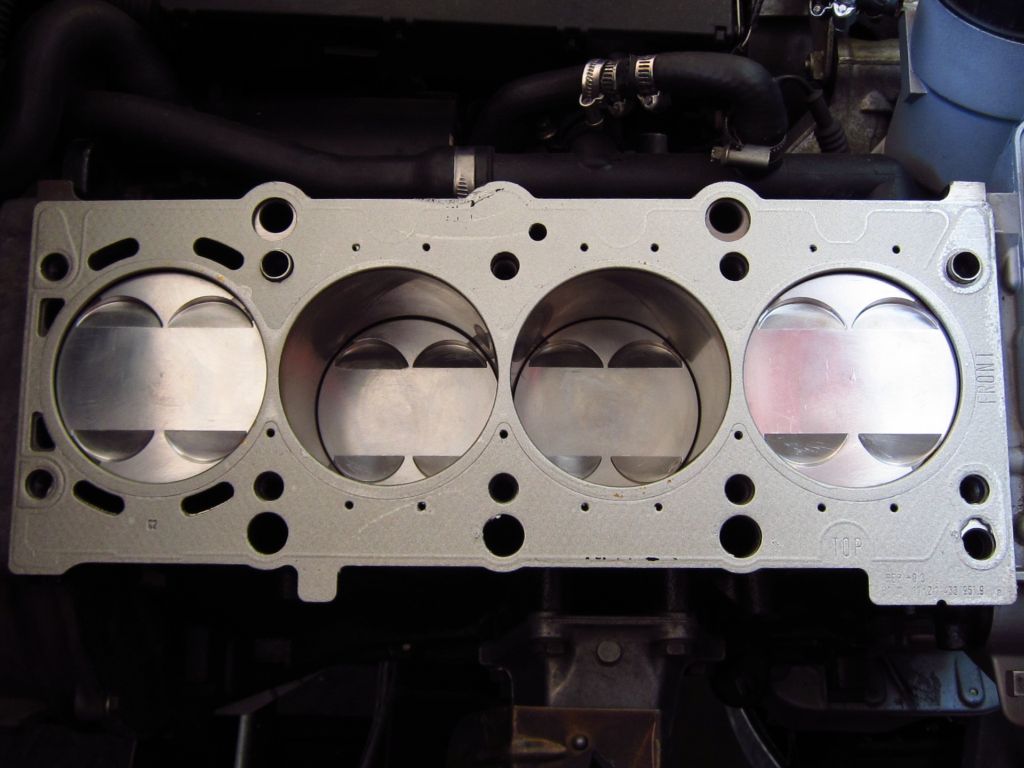

Here are some photos from back in 2013 when I was putting the head back on after MM repaired it from the valve spring failure.

Upper combustion chamber bits.

Piston #3 before I smoothed out the raised lip. Clearly there was also contact with the larger bottom surface of the valve. It is unknown whether this distorted the rest of the piston since, at the time, I was ready to roll the thing off of a cliff rather than deal with shipping the engine back to MM for a bottom-end inspection.

The valve that made contact.

The block deck when I was partially done cleaning it.

M44 +0.3mm HG in place with whatever spray coating MM had applied to it. I assume they went with +0.3 since they had milled the head 3 times by this point (once for the initial build, again when the first valve spring went, and a third time when the second valve spring went and they rebuilt the whole top end for me).

[/2013 content]

I am strongly considering a Cometic or Athena MLS HG for this next rebuild. I need to call up Cometic for some input, particularly about surface prep for their product. I have read that MLS gaskets require much more meticulous surface prep than OEM composite ones, so I may need to get it machined in order to properly use a MLS type. This isn't a highly stressed forced induction or race engine, so another M44 HG would probably be fine since I suspect that my issues are all due to 2013 being my first HG replacement experience and not properly preparing the block. But I'd feel better at this point with a MLS one, especially since I may need to go a few thousands thicker if the head and/or block are machined again.Leave a comment:

-

Yeah, it is a bit oily in there. I assume that some of it is from cranking it a bunch running the initial compression test. Fingers are crossed that it is just seepage from the badly compromised head gasket. I know for a fact that it was running pretty rich for a while during initial tuning work (Sssquid and I were doing it remotely), so the carbon buildup on the pistons is not unexpected. However, the other less-ideal culprits for oily residue are:

Bad rings

The engine has never overheated or had a lubrication issue. Rings were initially seated per MM's recommended procedure with conventional oil for 50 miles, then 500 miles, after which it has all been Mobil1 15W-50 full synthetic. When I pull the head and look at the cylinder walls, can those alone indicate excessive ring wear? Obviously, if there are vertical striations then I'd see that as a strong indication. But if the honing marks are still well intact, does that make ring wear less likely? None of walls showed visible vertical wear on the borescope. Back when the second valve spring went (before MM replaced all of the light single springs with a more OEM double spring setup), one intake valve in cylinder 3 did make contact with the piston, making a small mark on the edge of the relief which I smoothed out. It is unknown if this distorted the piston in any other way.

I assume that the only way that ring sealing can be evaluated is to put it all back together with a new HG and run compression + leak-down tests? The other option is to just pull the bottom end apart, re-hone and replace rings just to be safe. Swapping in a new HG only to find that compression / leak-down is no good would be frustrating. Thoughts?

Bad valve guides

Again, lubrication has always been maintained, so I'd assume that these would be OK unless they were all honed improperly from the start. All of the intake valves seem to look wet / oily, which is either seepage from the HG, bad valves, or maybe excessive compression leaking into the crankcase and forcing a lot of oil into the intake. I'll inspect the intake manifolds and ports once the manifolds are off.

Since the head is coming apart no matter what when I get it resurfaced, so the shop should be able to check guide clearances. A pressure test to detect cracks and valve sealing issues is also part of the plan.

The car has been consuming around 1qt of oil per 2000 miles. Some of that has been due to leaks from the timing cover / profile gasket butt-joint. Also, the amount of oil leaking from the timing case was always a bit surprising, so I am thinking that a long-term HG leak has been pressurizing the crankcase. It could also explain why I could periodically smell a PCV leak while it was running, despite never being able to find a leak and replacing all of the hoses and gaskets.

I assume that the rest of the oil consumption has been from excessive blow-by because the car has mostly been driven for short around-town type stuff and short joy-rides, so the warm-up duty cycle is high. I only ever once took it on a long drive, where it achieved 26.5MPG with me deliberately trying to get the best fuel economy possible (a few hundred miles on the highway late at night locked at 65MPH).

Still, if this has all been wishful thinking on my part and the oil consumption is way off, then I guess there's a lot more work to do.Last edited by bmwman91; 11-07-2019, 10:55 AM.Leave a comment:

-

This is the borescope I used. $200 isn't cheap, but it's super handy to be able to aim it. Professional ones are a LOT more expensive. Also, the little diagrams were made by me...the borescope does not come with software to do that.

https://www.amazon.com/gp/product/B00GY7C9ZW/

I will be stripping the head (maybe the whole engine) over the next week or so, and I will get a look at the ports then. Fingers are crossed that there are no cracks!

I'll get a look at the injector wiring to see if anything is amiss there. It's unlikely, but worth looking. Earlier in the year I was doing a lot of data logging to get the tune dialed in, and I had EGT probes for each cylinder. As far as I could tell, they were all within 5% of one another. I am having Sssquid clean and flow match the injectors anyway, though.Last edited by bmwman91; 11-06-2019, 09:16 PM.Leave a comment:

-

Gnarly, but not beyond salvation by any means. If you don't already have the IM off I'd be curious if you has a seal failure or crack at number three. Alternately, you may have damage in the number three injector loom, or maybe just a clog at the injector as a single cylinder massive over lean condition does not seem likely to be a management issue, but rather a physical failure.

Neat borescope, wish mine were aimable in that way. Model details if not egregiously expensive?Leave a comment:

-

Wow, thanks for the primer on that stuff, the explanations are good and clear.

Mass/Inertia

Yes, the low-hanging fruit is mostly claimed. The pistons & rods are already significantly lighter than stock, so changes there would be marginal. The crank is the 88mm M47 one, so it's a necessary mass increase that I am sure more than makes up for itself. I have MM's lightweight flywheel in there now. It's an M20 FW turned down to ~11.5lbs. More importantly, almost all of the mass was removed from that thick part of the cross section near the OD, so the polar moment of inertia was greatly reduced, which is what counts. The M20 PP & clutch offset that a bit since they are 228mm vs the M42's 215mm. Anyway, it looks like mine is 8lbs less than stock, but 4lbs heavier than the RHD one, with even more mass removed from the OD on the RHD one. The RHD one is so (relatively) cheap that I might consider it, especially if I end up pulling the engine to do the head and clean everything up nicely (or get the block re-decked).

Header

I'd believe that the stock 4-2-1 M42 header might be a bit under-size for the 2.1L. Again, Sssquid mentioned that he tuned a 2.1L with a larger custom header that responded well to it. I am seeing if he can track down some details. It's a bolt-on, so this is highest on my list since it's an hour to install once I am confident that a competent design is on deck. Sssquid could probably work up a new tune for me pretty easily (he and I have been collaborating on M42/Motronic 1.7 stuff for a couple of years now).

MM Engines

This makes sense. Given their prices and who I assume their target market is mostly comprised of, I can see them shooting for getting the best performance possible after making sure that idle, MPG and in-traffic behavior are nice and predictable. I have no idea what their race engines are like, but the "rally"/street engine I have fits your summary pretty well. It's more pleasant to drive as a DD than the stock M42 while also being a good deal faster. 195bhp from a 2.1L seems fair enough. You are way better informed on this than me...is getting above 100HP/L no longer a really big deal on a built NA street engine without major concessions to MPG and reliability?

Cams

It Cat Cams can work up a better profile for this engine that basically makes things better all over the powerband, I am up for giving them a call. These are bolt-ons for the most part, and I am sure I can get a good tune to go with them.

My preference is not to take a hit to fuel economy though...the car has been getting 18-22MPG since I put the engine in 7 years ago. I've been over every part of the fuel & control system in the car and replaced basically everything, so it isn't from that. The drivetrain is basically brand new, and the parking brake is correctly adjusted. Anyway, I assume it's just how the built engine runs. If this is an indication that something is very wrong, then I'm all ears.

Head

Yeah, I'd need to do some leg work to find a trusted, competent head specialist. I am not sure how many are in the region, but I believe that there are at least a couple. My inner OCD tendency is to want to do head + cams + exhaust all together and have them designed for one another. The realistic side of me figures that the exhaust & cams can be done individually to get things flowing better, and then if I do end up getting head work done, maybe the whole system together would be 90% as good as it would have been had it all been designed together. As far as I can tell, the big factor here is getting the fuel & ignition re-tuned to take advantage of the new system dynamics.

==================================================

I got a look into the cylinders with the borescope this afternoon. I noted multiple HG failures, and I assume that cylinder 3 was the source of the problem. Both cylinders 2 & 4 showed HG ruptures protruding into them, so there must have been a heck of a misfire in #3 at some point. Back when the crank damper went out, I was driving through my neighborhood under light load. The misfires occurred when limping it the last quarter mile home and while troubleshooting in the driveway, so no high RPM operation was occurring at the time. That makes me think that I may have made a mistake (or multiple) when installing the HG in 2013, and that whatever flaws there were in the assembly were made worse by the low-load detonations and then it finally gave up the ghost this last weekend. I'd bet that the inter-cylinder leaks have been there for a while as pin-holes, which would partially explain the bad gas mileage. My increasingly-poor idle and increase in engine/exhaust noise over the last few months could have been the leaks opening up further. Considering none of the external visual and electrical tests I did at any point came up with a cause, this seems plausible as a root cause.

Here are borescope shots of everything. I don't see any immediately obvious indications of trouble beyond the multiple HG failure sites. Despite my best efforts to vacuum all debris out and away from the plug holes, crap still made its way in, so I am not bothering with any compression tests and just going straight to pulling the head. Turning the crank with a wrench also aligns with what I can see. Cylinder 1 has the expected compression/resistance, cylinder 4 has a little resistance and there is none from 2 & 3. Basically, I am sort of surprised that it was running at all.

EDIT: Now that I look closer, #1 might have also been leaking with #2. Not enough to rupture, but there is a suspicious amount of carbon buildup. Anyway, the period of time in 2013 when I did the HG was not a good point in life on multiple fronts, and I was ready to sell the E30 just to be rid of it. I was stressed, sleep deprived and rushing the repair despite it being my first time doing it. If I really did that poor of a job, then I am glad it failed enough to be obvious so that I can take my time and do it properly this time. I almost don't want to post these pictures because it's embarrassing to believe that I may have done it so poorly!

Cylinder 1

Cylinder 2

Cylinder 3

Cylinder 4

Last edited by bmwman91; 11-06-2019, 07:43 PM.

Last edited by bmwman91; 11-06-2019, 07:43 PM.Leave a comment:

-

Some food for thought

Mass/Inertia

I look at it like this, if you want to reduce the inertia of the engine to make it rev quicker you target the biggest inertia which will be flywheel so if you don’t have a RHD lightweight FW then you are not picking the lowest hanging fruit so going nuts on the other stuff is not the best approach.

After the FW probably the crank (excluding the clutch pressure plate) is the next big ticket item and the big end weight of the rod. I wouldn’t be targeting the big end weight too much because the metal around that helps keep the big end tunnel round under load to keep the bearing lubricated properly.

Without question the best way to make the engine rev faster under load is make more torque/power. The lighter inertia helps in first gear and a bit in 2nd. In 3rd the effect is essentially negligible.

Header

The header does need to be big but it needs to align with the ports and transition smoothly and the smaller the pipe the more it matters. The length is important as runners in the 18” range tune in at too high of an rpm to be useful on a street engine. i haven’t done much modeling of 4-1 or 4-2-1 system to give too much insight other than 4-2-1 on a V8 seems to be better for rpm we are dealing with here.

MM Engines

The underlying philosophy behind what seems like most of their engines is a bias towards fuel economy, emission and smooth idle by limiting what they do on the exhaust side and with cam timing (lobe centerlines). For a street engine it’s certainly a balancing act but IMO they are too far to the left for most.

A high performance engine must use the exhaust side to do the following- Have enough “time-area” to exhaust/evacuate the cylinder sufficiently such that the cylinder pressure reduces as low as possible prior to the induction starting;

- Pull additional depression on the cylinder to support 1) and get the inlet charge moving before the piston starts moving;

- Have the exhaust valve to open as late as possible to extract all the energy yet still have sufficient time area to achieve 1).

Cams

The cam lobe profiles MM use are pretty aggressive which is good, by aggressive I mean- the duration numbers at high lift are good;

- the lift is reasonably good so the area under the lift curve is good; and

- they don't use excessive duration.

- The exhaust duration is pretty conservative which is ok if the engine has a good efficient exhaust system but if you are using a stock-ish setup then this costs mid to topend power.

- The lobe centrelines they use are designed for fuel economy and emission, as such they are very wide which limits overlap and the engines ability to do 2) and 3) does not occur either. It’s the exact opposite of what you want for WOT performance specifically bottom end to mid range.

For the ST on back of valves, it seems that the angles on the valve seat, backcut and margin are sufficient enough to shear the fuel adequately. Unless I see A-B tests confirming that kind of stuff then in my mind it’s still just theory. My thoughts are there might be merit in textured surfaces but the scale and shape are important and it probably needs to be smaller scale (finer grooves/texture etc) to actually work.

To make more power often you need to open the restrictive parts of the head up, without knowing stock M42 head details it could be oversized already from the factory as many early 4V are, so the porting approach is different. If One thing for sure is if you open the head up the flow should increase accordingly and the flow divided by area (average velocity) should increase otherwise the engine will be a dog.

Good cylinder head specialist will be able to improve I’m sure. The issue is finding someone.Leave a comment:

Leave a comment: