The auto-moderation seems to flag a post as SPAM if it is edited multiple times or (maybe?) has certain words).

Yes, that was one thing that gave me pause. The ultra-ultra light stuff they are just coming out with has not seen a tremendous number of miles yet, and given my increasing desire to not have to mess with this engine much more, I am largely tempted to keep the bottom end as-is if it is not damaged. And yes, durability is probably not going to increase so significantly that I ever notice since even stock heavy stuff can go for half a million miles in many cases. MM's logic is that reducing the reciprocating mass frees up a fair bit of kinetic energy, particularly at higher RPM, to be put into the drivetrain instead of accelerating piston/rod assemblies. Technically it makes sense, but there's the big question of just how worth the money it is. The thing already revs like a crazy animal, and for the (I assume) $5K+ it would cost to ship + rebuild the bottom end, I could probably do all of the stuff you suggest while leaving the already built bottom end alone.

- Sssquid mentioned another 2.1L M42 that he tuned had a higher flowing header, and that it made a noticeable improvement in performance. I'll see if I can track down specifics.

- Interesting about the cams. It looks (from your build thread) that you have used some MM stuff int he past. Is it your experience that they are being conservative with their cam profiles? Also, what is your take on their surface turbulence valves?

- The head is MM's usual moderately opened-up one, which as far as I can tell is a reasonably conservative porting. This area, specifically, is where I would need to sit down with a competent shop and discuss what all could / should be done to keep a balanced torque curve while allowing for better flow & gas dynamics.

- ITBs. There are a couple of bolt-on options that I know of (dBilas, RHD), so that would be easy enough, logistically. I have heard that the dBilas setup is not terribly well optimized for the M42, which is why RHD developed a well engineered kit.

Agreed about the spare head. If I am going to do any amount of head work, it would best be done with a clean original one.

If you don't mind sharing some guidance once I know for sure what broke, and how far down the rabbit hole I want to go with this, then maybe I could rekindle my desire to get from ~95HP/L to over 100.

M42 Head Gasket Blown, Project Thread

Collapse

X

-

what happened to some posts?

Their recent M20 piston stuff is 245g so another 50g off is huge when the physical size is about the same and id be worried about putting that in an engine without them having test mules that have done 60,000 miles. The fancy slipper design light weight pistons have a tendency to crack when they get light especially with lightweight wrist pins. The combustion loads are quite a bit higher than the inertia loads so I don’t see huge gains in durability with overly light parts, seems like mostly risk. It’s not a race engine that gets torn down often.

some ideas from me

- a tri-y style header with about 24" primaries 1.5" diameter would be a good fit

- a catcams http://www.catcams.com/products/cams...nguage=english with cam centrelines much tighter than what MM recommend

- cylinder head depends what it flows, what the cross sectional areas are and resulting velocities are as to how efficient what you have.

- ITB seem to work well.

i'd probably get a good core and find a specialist to do some head work new cams etcLeave a comment:

-

Yeah, 2.1L rally from Metric Mechanic. They have been cooking up some pretty crazy stuff in the piston & rod department in the last 7 years: pistons at 195g vs. the 310g in there now, rods at ~350g vs 500g in there now. Obviously MM is going to try to sell these things pretty hard since they are a business, but if it does end up being the case that I need bottom-end work, I might go that route. We'll see...it wouldn't be cheap for the kind of returns I'd see, and an MM engine is already high on the $/HP chart.

As far as breathing mods, I have thought a bit about that. I like the mid-range power that it makes now and don't want to end up taking a big hit there. I'd need some input from some experienced builders to determine the right amount of porting to do in the head, and what could be done with the exhaust and intake while keeping a balanced torque curve. I know that the conventional wisdom is that opening things up "is bad for low-end", but I have also seen a number of engines not have that be the case after a proper tune. People who actually spend the time to learn the science and engineering behind optimizing air flow must roll their eyes at such statements. I know enough to know I don't know enough to make flow modification decisions myself and expect good results! I always wanted to go super technical on engine operation and optimization, but my technical hobbies and career all sort of veered away from cars over the last decade and I probably won't have the time to try to become proficient in that area any time soon, as much as I really would like to.Last edited by bmwman91; 11-05-2019, 08:11 PM.Leave a comment:

-

Detonation can cause piston material to deposited on the plug sometimes but is probably unlikely.No additives at all. And no, I do not believe that any of the contamination on the plugs was aluminum, although I can't really test to be certain. What would aluminum on the plugs indicate to you?

And yeah, possible tinkering. I was on the phone with MM earlier. While it might not really be something I have budgeted for, it sounds like they have vastly improved upon the ultralight rods and pistons that they use. The stuff in there now is about half the mass of stock, and their latest and greatest stuff is nearly 40% lighter than what is in there now. That would be some real tinkering lol...ship the engine back out there and have the moving bits in the bottom end lightened up even further. It'll all depend on what I find when I get in there. MM thought that seeing low compression on cylinders 1 & 4 could also be a sign that there are bigger issues, like burned valves or shot rings, but considering that the thing will still run on those cylinders, well enough to limp home, and the failure occurred under light-load in 5th gear put-putting around town, I am hoping (living in denial?) that it's just a crappy tester and maybe fuel-washed walls. The valve timing is, as far as I can tell, just fine since the M42 makes distinctive noises when valves meet pistons. Since cylinders 2 & 3 registered as ZERO on the gauge, I think it might well be the gauge since I'd expect at least a few PSI from cranking with just a hole in the HG.

Don’t you have the 2.1 rally? Like ~300g piston and ~500g rod? You aren’t going to make big savings on that and any savings will give minimal tangible effect as the durability is probably already well in excess of what you need and any change in mass moment of inertia is a small part of the total system inertia.

IMO You want to focus on breathing mods, not reduction of mass.

Yes, a zero reading is an indicator of a rather large hole.Last edited by digger; 11-05-2019, 02:34 PM.Leave a comment:

-

No additives at all. And no, I do not believe that any of the contamination on the plugs was aluminum, although I can't really test to be certain. What would aluminum on the plugs indicate to you?

And yeah, possible tinkering. I was on the phone with MM earlier. While it might not really be something I have budgeted for, it sounds like they have vastly improved upon the ultralight rods and pistons that they use. The stuff in there now is about half the mass of stock, and their latest and greatest stuff is nearly 40% lighter than what is in there now. That would be some real tinkering lol...ship the engine back out there and have the moving bits in the bottom end lightened up even further. It'll all depend on what I find when I get in there. MM thought that seeing low compression on cylinders 1 & 4 could also be a sign that there are bigger issues, like burned valves or shot rings, but considering that the thing will still run on those cylinders, well enough to limp home, and the failure occurred under light-load in 5th gear put-putting around town, I am hoping (living in denial?) that it's just a crappy tester and maybe fuel-washed walls. The valve timing is, as far as I can tell, just fine since the M42 makes distinctive noises when valves meet pistons. Since cylinders 2 & 3 registered as ZERO on the gauge, I think it might well be the gauge since I'd expect at least a few PSI from cranking with just a hole in the HG.Leave a comment:

-

there are a lot of dodgey comp testers out there. people say its consistency across cylinders that matters but the absolute numbers means something as well.

are you using any kind of additive in the fuel like octane booster or cleaning agent? none of those flecks on the plugs looked like alumnium did they?

good news is if/when head comes off it means there's scope for some tinkering.....Leave a comment:

-

I got a little bit of prep done after work today. Mainly, I wanted to completely drain the coolant using the block drain so that there would be an absolute minimum of coolant left in the head. It makes a bit of a mess when you pull it off! I am being extra careful because the repair will be done in my garage, where my cats have access. Coolant is EXTREMELY toxic to cats, who like its taste and smell, and it causes an agonizing death. Anyway, I carefully drained it from the radiator first, and then got the rest out from the block drain using a funnel with a hose under the outlet. There was minimal spillage from there, and I just rolled the car back out into the driveway to hose things down. It'll sit there to dry for a day or two since I have limited time during the week, and it gets dark earlier now with the time change and all (I do not like Daylight Savings Time). I am sure my neighbors are used to seeing me manually pushing the car around in the driveway by now lol.

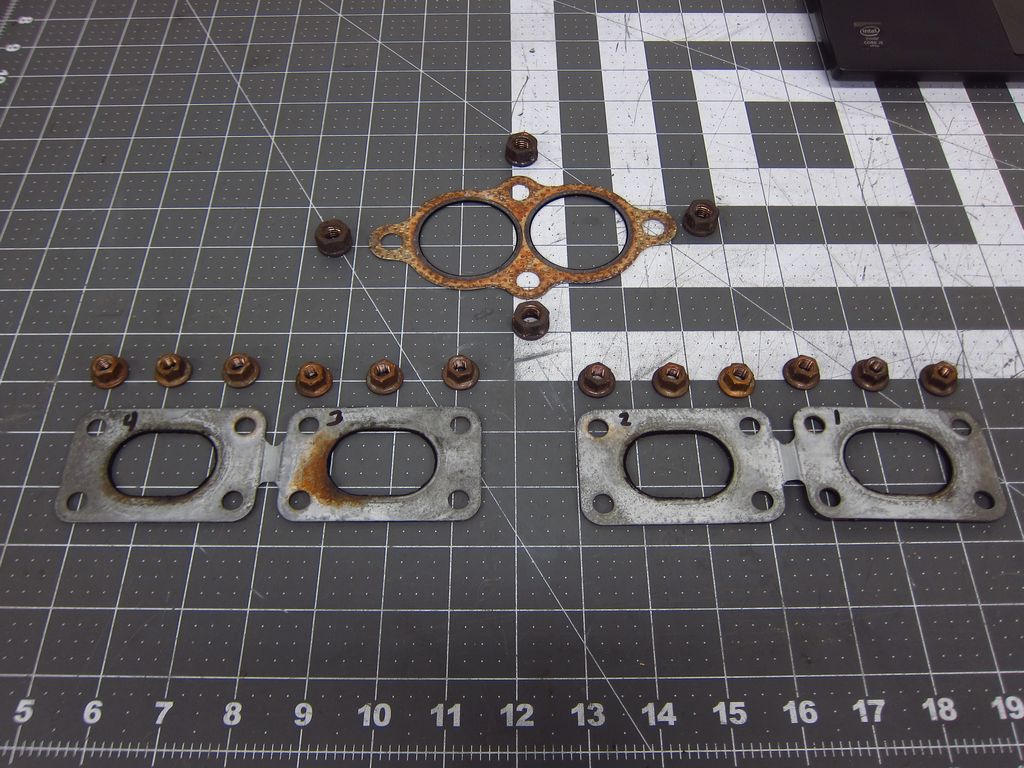

As a part of getting the funnel under the block drain, I removed the exhaust header. It is super easy to do if you remove the right side engine mount arm (support the engine with a jack). It slides right out the front...as long as you do NOT have A/C installed. If you do have A/C, then you either need to remove the compressor, or the sway bar (and even then I am not sure if it would go out the back).

The coolant did not quite look right. I'd say that combustion gases were definitely making their way into places that they did not belong. This coolant is less than a thousand miles old!

A good amount of debris came out with it, after using the block drain. The dark stuff was almost all magnetic, and I am guessing that this is burned head gasket material.

There was also this bit of paper material in there. I'd guess that it is not from this failure since it does not look burned. Maybe it is just crap from a past gasket that I scraped.

There was a little bit of an indication of trouble (maybe) at cylinder #3's exhaust port. I am guessing that some of the large detonations that occurred in the exhaust when the crank damper was failing had damaged the gasket. It would explain why I thought that the car was making more exhaust noise than usual.

That is it for today. Next steps in the immediate future will be to re-run a compression test after re-charging the battery fully, and using a better compression test kit. It irks me a little than cylinders 1 & 4 were reading low with the loaner compression gauge, and I can't imagine that all four cylinders went out together. Besides, if they were totally shot, I wouldn't think that the engine would run on 2 cylinders at all, let alone enough to get me the last mile home. After the compression test, I will start stripping the rest of the stuff off of the head in preparation for its removal.Leave a comment:

-

OK, well fingers are crossed that it's just a straightforward HG failure with no collateral damage. It's good that it was #2 & #3 since their compression & exhaust strokes coincide, so they never really had an opportunity to build much compression and ignite the mix...one would just push most of its air/fuel mix out the other's exhaust.

And yeah, pile-o-rags it is to deal with the oil. Pushing the car out to the driveway to drain the coolant is doable, and running a hose through the system seems like the fastest way to get the coolant out so that the cats won't find anything to drink when it is back in the garage.

I'll see about yanking the valve cover this evening to poke around up there for any signs of distress. In a couple of days I should have a rigid/controllable endoscope so that I can look up at the valves and HG interface from the spark plug holes. Even though I am 99% sure that the head is coming off no matter what, it'll likely be a few days before I hear back from Metric Mechanic about updated cams, so I'll leave the head on the car until I know if I am getting it machined locally or shipping it to them.Leave a comment:

-

Yes, absolutely, metal bits could have come off, but then again this isn't exactly a race engine built to the nth degree, so who knows.

As to minimizing mess, the coolant isn't too big of a deal as you can always drain first, refill with water and drain again. As to oil, the cam tray area really holds a lot of oil, so at best you might be able to bungee a skirt of rags to the block.Leave a comment:

-

Yeah, I am trying to figure out how to proceed with additional diagnosis without jumping right into pulling the head. I have a cheap USB endoscope that I can try to get a look at the piston crowns with, and I can pull the manifolds to verify that the valves are closing. Still, 0PSI on adjacent cylinders and being able to detect air passing between them seems reasonably conclusive. I have no experience with this particular failure...what sort of carnage am I looking at with an inter-cylinder blow out? Could chunks of metal gasket have broken off and damaged a cylinder wall or valve? My bet for what damaged the thing is the totally bad ignition timing when the crank damper wheel failed. It did a fair amount of pinging for 10-20 seconds.

Plugs being rich is expected since I was doing a lot of tuning earlier in the year, and the car was running pig-rich for a while. But yes, the deposits on #3 & #4 are a little odd and I am not sure what the build-up is.

Got any pro-tips for how to minimize the amount of coolant and oil mess that I get when I pull the head? Last time I did it, I got a lot of coolant spillage even after draining it. It was a mess, and I don't want my cats getting at it (although I could push it out into the drive way for removal and then push it back in).Leave a comment:

-

Well, that's unfortunate, but the lack of exhaust gas in the coolant or coolant in the oil really bodes well for a relatively quick fix. However, I'd still dig in to the failure mode a bit more before yanking the head, even though it's not exactly a difficult task mechanically. Maybe start with a borescope/endoscope to check out the cylinders in question? If you do remove the head you'll need to pick your poison as to how you plan to clean the block surface as it's going to be a mess if there was a cross cylinder failure. Plugs look on the rich side of normal, with more deposits than I am used to seeing.Leave a comment:

-

M42 Head Gasket Blown, Project Thread

This will be my project log + my questions thread that I document as I sort things out. It may well be a couple of months from now until it's finished.

It looks like it is time for more M42 wrenching. Other than replacing the crank damper wheel and some miscellaneous stuff around there earlier in the year, I have not had to touch this engine since ~2013. Some of you will recall that I had Metric Mechanic build me a 2.1L stroker, which at the time had a couple of valve spring failures, so I had the head off and replaced the HG back then. Maybe I messed something up then, or maybe when the crank damper was coming apart and the timing was way off some of the resulting detonations damaged it, or maybe it is just the result of me driving the living shit out of it lol. Whatever the case, I am 95% sure that the HG is toast between cylinders 2 & 3.

I got a loaner compression test set from the local parts store and saw:

Cyl 1: 70 PSI

Cyl 2: 0 PSI

Cyl 3: 0 PSI

Cyl 4: 50 PSI

This was on a luke-warm engine with a loaner gauge that was probably abused, so I am not really super concerned about #1 and #4. The fitting for the spark plug holes could only be tightened down onto the o-ring with the hose coming off of it, so there was probably just a ton of leakage. Anyway, given that two adjacent cylinders have no compression and I can basically hear air exchanging between them if I put the shop vac onto one spark plug hole, I am assuming that the web in the HG between these went out. I was maybe a mile from home on the expressway when I noticed that the car would not make more power when I got onto the throttle, and I thought that I heard some pinging or other not-good noise for a few seconds before it just kind of ran poorly. I got it home and it certainly seemed to not be running on all cylinders, as well as intake+exhaust notes which sounded like air moving to wrong places at the wrong times. My very first thought was that I got bad gas since this all started about 2 minutes after refueling.

As far as I can tell, the oil is not milky. It's pretty clean since I just changed it 1500 miles ago, which at first made me think it was contaminated, but I think I was just being paranoid. Also, the coolant level in the expansion tank was not altered, so exhaust products don't seem to be making their way into the cooling system. Anyway, how long do you usually find that it takes to turn the oil noticeably milky when a HG is going? I suppose it varies depending on the severity. If I am having this hard a time telling, then either no coolant got in, or I caught it early. I'll drain the oil anyway just to make sure later on in this project.

The M42 HG is pretty straightforward to swap, assuming it is the only casualty there. I am going to have the head milled, but I am also going to check with MM about some newer cams. Apparently a few years after my build, they came up with a new cam profile which boosts top end power 10-15HP, with minimal loss in the mid-range. Maybe I will send them the head for a little refresh and new cams while I am at it. If not, then I will just do it locally since there are competent head machining shops in the area. Decisions, decisions.

So far, here is a list of what all I am replacing as part of the project:

Head Gasket (OEM metal M44, probably)

Head bolts

Inner profile gasket

Outer profile gasket

Upper timing case cover gasket set

Thermostat housing gasket

Thermostat o-ring

TB gaskets

Lower intake manifold gasket

Upper intake manifold gasket

Exhaust manifold gaskets (head and cat pipe)

Rubber exhaust hangers

Engine-to-chassis ground strap

Alternator-to-engine ground strap

Hood-to-chassis ground strap

Spark plugs (all)

Ignition coils (all)

Is there anything else I am forgetting? Earlier in the year I did the water pump, thermostat, alternator bushings, belts, VC gasket, coolant temp senders (both), cam & crank position sensors and crank damper.

Other thoughts/questions:

I recently picked up a 2006 Jetta TDI, which has been my DD. So the E30 has been getting driven a LOT less, like once every 2 weeks. This makes it a little tougher to diagnose recent symptoms since I have not been driving the E30 much.

I am curious about whether some of my mysterious intermittent poor running is maybe from this thing being partially failed for several months? The car has been acting weird in that about 60 seconds after a cold start, it has trouble idling for maybe 5-10 seconds, and then it goes away after blipping the throttle a couple of times. The ICV is clean, so I am pretty sure it is not that. Could the HG have been leaking a little between #2 & #3 for a while, and it just now fully blew out? It's been doing this for maybe the last 5000-7000 miles, slowly getting worse. I have probably replaced every sensor on the car, and none of it completely fixed the issue.

The last couple of times I drove it, it seemed to be a little hard to start as well. Other than that, it has been running strong all the way up to 7500RPM.

The ICV is making an audible clicking/whirring noise when the car is parked in accessory-II mode. I don't ever recall noticing that before. The tone seems to change if I push on it / move it around. Is this a sign of a dying one?

Here are some shots of the spark plugs that I took today when doing the compression test. These are maybe 15K miles old, and have been through a LOT of fuel/ignition tuning. Do you agree that they mostly look like they have been through some rich running, and hard driving, but nothing much else obvious?

#1

#2

#3

#4

Tags: None

Tags: None

Leave a comment: