Yeah, that plastic is definitely a chunk of cam gear.

Nice work on the pan!

318is M60 swap

Collapse

X

-

I'm fairly certain that the black plastic parts in your lower oil pan came from the cam gears.

Remove your valve covers & look at the timing gears themselves.

Especially the rear side of the gears.

The teeth on these gears are isolated from the center of the gear pulley by plastic.

The only other plastic parts in the front of the engine are the timing chain guides.

But those are either perfectly straight, or slightly curved (not as curved as what I see in your picture)

That's the best educated guess I can offer. :neutral:

Good luck with your build.

I'm also sourcing parts for my own '91 318is m60 conversion. :)Last edited by ///eMveee; 09-09-2014, 10:58 PM.Leave a comment:

-

Long overdue update with some pics. Shitty pics from my potato and only taken when I remembered....I suck.

Working on my swap has been slow but just picked up again. Got a new flywheel and clutch, picked up a used alternator and starter. Placing a large order to pelican soon. Trying to make sure that I want to order from them. Ordered the garagstic transmission cross member extension for my 6-speed.

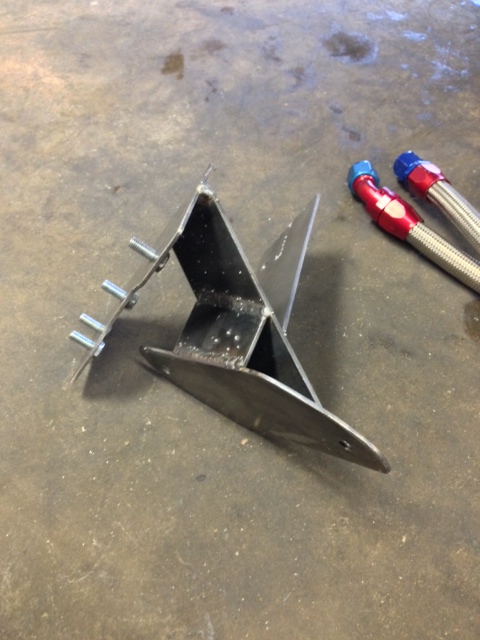

I finished up my removable core support finally.

I ended up welding this on the back side of where the top of the rad support connects. Seemed flimsy up there and I was worried about fatigue. Here it is spot welded in.

Don't have one of it all welded up, here is one with nuts tacked on too

Cut down the steering rack mounts to fit my m3 steering rack. No shots of it welded up...,

Just got my spool gun for the welder so I went to attack the oil pan notching. I know this isn't the best route, but I won't have access to a tig for a few weeks and didn't feel like waiting around any more. Took me a while to get the welder dialed in, initially started out waaaaay too hot and too much wire. You can tell big time on the cast, blobby welds and such. Forgot to snap some better pics of when it got better.

Now here is what I found in the oil pan when I pulled it.

The bolt from the oil pump I know is common. Had the same thing with the m42. But the seal, anyone with ideas where it is from so I can replace it?

Still need to finish up the mounts for the windage tray on my oil pan. I will take some pics of that too.Leave a comment:

-

My issues were with the filters developing pinhole leaks (went through about 20 filters of various brands). Ryan has the same issues.

In addition, I had to buy 3 filter brackets before I received a leak free one. Ryan's leaked as well.

I'm currently using AN lines, I had AN fittings brazed onto the factory hard line fittings, and am using the X5 adapter plate on the block with AN fittings welded on. I have a slight leak from one of the fittings, it's just wear from dissembling and reassembling probably 50 times.

I blew out another oil filter, even with that box that I built covering the filters. That was it, I had enough.

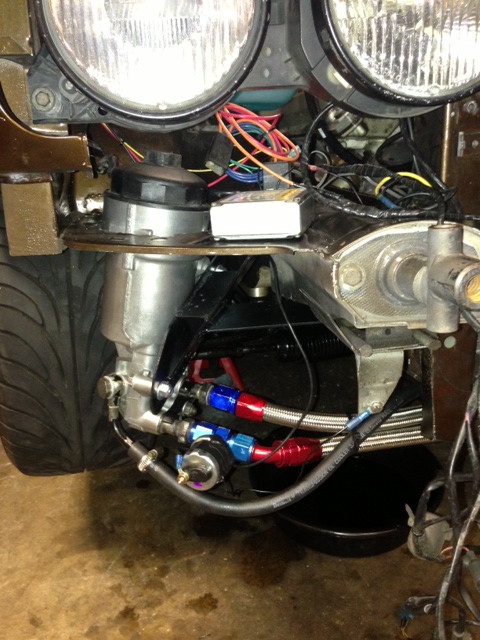

So i installed the factory m60 oil filter housing, remotely, with AN hoses/fittings. This should solve my problems. It's a hell of a tight fit, between the valance, fog light, tire, frame rail, fender, wheel housing, etc... I have about 1/2" of clearance in any direction. It took me about 15 hours to do all of this.

Had some 10 AN bungs brazed onto factory metal lines that I cut down:

Clearance with the wheel turned (had to trim the corner of the housing off):

Clearance with the wheel straight:

Road clearance:

That black hose is just the filter removal drain. When you start removing the cap, the filter lifts up, and a push-button valve at the bottom is opened, draining the oil back to the pan so it doesn't spill everywhere. I haven't tested it yet, it's all gravity based, and I don't have much of an incline between the filter housing and the pan. We'll see. If it doesn't drain properly I'll just put a ball valve at the end and open that while I'm draining my oil pan, to drain the housing when changing oil. In addition, that's why I'm not terribly concerned about the ground clearance. It serves no real purpose other then not making a mess when changing oil.Leave a comment:

-

Hmmmm great thanks for the input. I suppose then I need to find someone nearby who can make custom lines then. Unless the stock lines prove long enough to mount it somewhere that looks good.Yes, if you ditch the factory oil cooler setup, you can just put a 14x1.5 bolt in the pan.

I'd recommend against doing that though. I spend hundreds of dollars on parts, multiple tow truck rides, lots of fabrication time, more frustration then you can imagine, and the bottom of my car has a coating of oil... all due to those damn screw on remote filter things. I finally switched back to the stock housing, remotely located, and have been 100% problem free since then. Ryan has been through the same crap, and I believe he is switching back as well.

Would it still be a bad idea to convert to AN fittings? That would make doing the lines easier. Were you leaks only from the filters themselves or did you have problems with the AN fittings or lines?

ThanksLast edited by LoneWolf; 04-24-2014, 10:00 AM.Leave a comment:

-

What are you guys doing about the where the oil pipe outlet connects to the top of the oil pan? It's number 12 on this diagram http://www.realoem.com/bmw/showparts...14&hg=11&fg=30

Planning to just use a relocation kit with screw on filters, are you guys just capping off that oil pipe outlet meets the oil pan?

Yes, if you ditch the factory oil cooler setup, you can just put a 14x1.5 bolt in the pan.

I'd recommend against doing that though. I spend hundreds of dollars on parts, multiple tow truck rides, lots of fabrication time, more frustration then you can imagine, and the bottom of my car has a coating of oil... all due to those damn screw on remote filter things. I finally switched back to the stock housing, remotely located, and have been 100% problem free since then. Ryan has been through the same crap, and I believe he is switching back as well.Leave a comment:

-

I am hoping to have it all back together and make bimmerfest this year. For now I have put the forced induction on the back burner, just want to get it done and work out any bugs before I throw FI into the mix.

Unfortunately life got busy and winter made the garage unbearable. Now that spring is heating up I'm getting back in gear.

Picked up a new flywheel, e36 m3 steering rack, new starter, ordered some more parts from pelican. Also picking up a mishimoto z3m radiator from a friend. Still need to pick up a the valve cover gasket set and shortblock gasket set. That wasn't needed for fabricating mounts so I have held off on ordering them. Once everything gets in I will post some updated pictures. Hopefully post some pictures of progress from the weekend.

What are you guys doing about the where the oil pipe outlet connects to the top of the oil pan? It's number 12 on this diagram http://www.realoem.com/bmw/showparts...14&hg=11&fg=30

Planning to just use a relocation kit with screw on filters, are you guys just capping off that oil pipe outlet meets the oil pan?Last edited by LoneWolf; 04-24-2014, 08:54 AM.Leave a comment:

-

Nice work Zach, I know this is a reach but whats the eta? bimmerfest east?Leave a comment:

-

-

I didn't realize that the cams from the M60 would not fit the M62 heads. Guess that shoots that idea down.I've been doing the research on an M60 swap for a little bit here and can say i've honestly never heard of anyone putting M62 heads on an M60, so gettin info on that might be tough. Also from my research, the M60 cams will not fit the M62 heads. I think this is the major reason people take the full M60 heads and place them on the M62 block.

Not really after the extra displacement of the m62, the extra .4 liters, was really just wondering if I could use the heads from the M62 as a cheap way to lower the compression more than just a head gasket and cost less than going new pistons and sleeving./you can run plenty of boost on stock m60's with stock metal headgaskets. the gasket wont be the first to go, the pistons will if your aren't tuned.

if you have a future with boost in mind then I don't see .4 liters helping much to a point that boost wont make up for it.

Id spend that time and money on getting the heads refreshed/ported or sleeving the block for after market forged pistons.

Looks like I will be boosting on stock internals and all then.

Snuck into the garage between shoveling.

Success!!!

Turns out the RPM sensor was the hang up......and I am an idiot

Once I removed it everything slid right off, no hammering needed. Luckily haven't been really hammering too hard.

Other good news, I ventured out into the snow today and picked up the cord I needed for the welder.Leave a comment:

-

/you can run plenty of boost on stock m60's with stock metal headgaskets. the gasket wont be the first to go, the pistons will if your aren't tuned.

if you have a future with boost in mind then I don't see .4 liters helping much to a point that boost wont make up for it.

Id spend that time and money on getting the heads refreshed/ported or sleeving the block for after market forged pistons.Leave a comment:

-

I've been doing the research on an M60 swap for a little bit here and can say i've honestly never heard of anyone putting M62 heads on an M60, so gettin info on that might be tough. Also from my research, the M60 cams will not fit the M62 heads. I think this is the major reason people take the full M60 heads and place them on the M62 block.Leave a comment:

-

Can't I swap my m60 cam and gears over? I imagine the dual springs too? I would be losing some flow with the m62 heads, but maybe porting them a little makes up for that?The m60 heads do have more aggressive cams (duration and lift), as well as double valve springs. And yes, the m62 uses a single row timing chain, yet another weak point.

Why don't you call companies like Cometic, etc... and ask about a head gasket? If somebody makes a head gasket for one side of an m60, they obviously make it for the other side as well...

I just can't imagine taking all of the worst parts of both engines and combining them for the simple goal of lowering compression, from what, 10.5:1 to 10.0:1? You're left with the weaker cams, single valve springs, single row timing chain with the terrible bottom guide rail, and most importantly, .4 liters less displacement (probably negating any benefits of running more boost from lower compression to begin with...)

How much boost are you going to run that you need to lower compression? I've seen guys put down 500-600+hp on stock m60's. You could probably push 8psi on the stock old head gaskets reliably, good enough for 400-500 whp on a good turbo setup. And if you want to run more boost then that, you'll be spending serious money anyway, why not just sleeve the block and use aftermarket pistons?

Just trying to think outside of the box here and bounce some ideas around, the feedback is really appreciated.

Definitely still exploring the head gasket, haven't given up on that by any means.

The m60 has a compression ratio of 10 to 1, can't seem to find out was cc the m62 heads are and anyone that swapped them onto an m60.

Sleeving the block and lower compression pistons is probably somewhere down the road, would like to anyways, but only after getting it all together for a bit. Maybe build that short block once the engine swap is ironed out and swap it in.Leave a comment:

-

The m60 heads do have more aggressive cams (duration and lift), as well as double valve springs. And yes, the m62 uses a single row timing chain, yet another weak point.Huh, thought I remember reading that the m60 heads flow only a little better, and that the m60 just has more aggressive cams? The hang up is the single row chain on the m62 heads right? Guys have frankensteined the m60 heads onto their m60, just wondering if its possible to reverse it.

I haven't been able to find a thicker head gasket, well I did but only for cylinders 5-8. Do you know where I can find the set?

Plus the head gasket will only drop compression to around 9.8 to 1.

Would like to lower the compression for boost.....

Why don't you call companies like Cometic, etc... and ask about a head gasket? If somebody makes a head gasket for one side of an m60, they obviously make it for the other side as well...

I just can't imagine taking all of the worst parts of both engines and combining them for the simple goal of lowering compression, from what, 10.5:1 to 10.0:1? You're left with the weaker cams, single valve springs, single row timing chain with the terrible bottom guide rail, and most importantly, .4 liters less displacement (probably negating any benefits of running more boost from lower compression to begin with...)

How much boost are you going to run that you need to lower compression? I've seen guys put down 500-600+hp on stock m60's. You could probably push 8psi on the stock old head gaskets reliably, good enough for 400-500 whp on a good turbo setup. And if you want to run more boost then that, you'll be spending serious money anyway, why not just sleeve the block and use aftermarket pistons?Leave a comment:

Leave a comment: