they usually get around it by using calipers with 2 different piston sizes. Smaller piston provides more clamping force during light application of the pedal. Only thing you have to be wary of is if you are racing on the setup or you trail brake at all, you often find problems with tapered pad wear. Part of the pad running on the small piston wears down really fast due to difference in force applied.

Running new lines is real easy if you get a decent quality brake tube. Some are just way too hard an inflexible, makes it really difficult to manipulate even with benders. The good stuff you can pretty much bend by hand, makes everything really easy.

Fronts were simple, just used a new T piece, one outlet runs to the master, then one side each to the caliper (left and right). Seeing as the master is on this side of the car, I didn't bother removing all the lines for the calipers to reposition them on the other side of the car near the pedal box. Just ran a new line from the master across the firewall to the T piece. Easy case of just tweaking the existing lines a little to fit into the T piece perfectly. Mounted it solid against the strut tower with a rivnut. I'll probably remake the caliper lines when I pull the engine next time and run everything real tight against the sheet metal as I want to try and locate the power steering reservoir and possibly dry sump reservoir behind the tower in (thinking of maybe relocating the fuse box), but for the time being, it works flawlessly. Also seen in the pic is the new line to the rear brakes. Runs from the master, through an adjustable proportioning valve, then joins up with the existing brake line running to the rear (where the original valve used to sit). When I remove the lines again im going to use flare nuts for the rear which have a notch cut into them to locate them with a clip, so I can position it back through the hole where the valve used to sit.

It's all neat and out of the way, can't even see it when you open the engine bay. It all runs across the firewall and down just below the C101 plug.

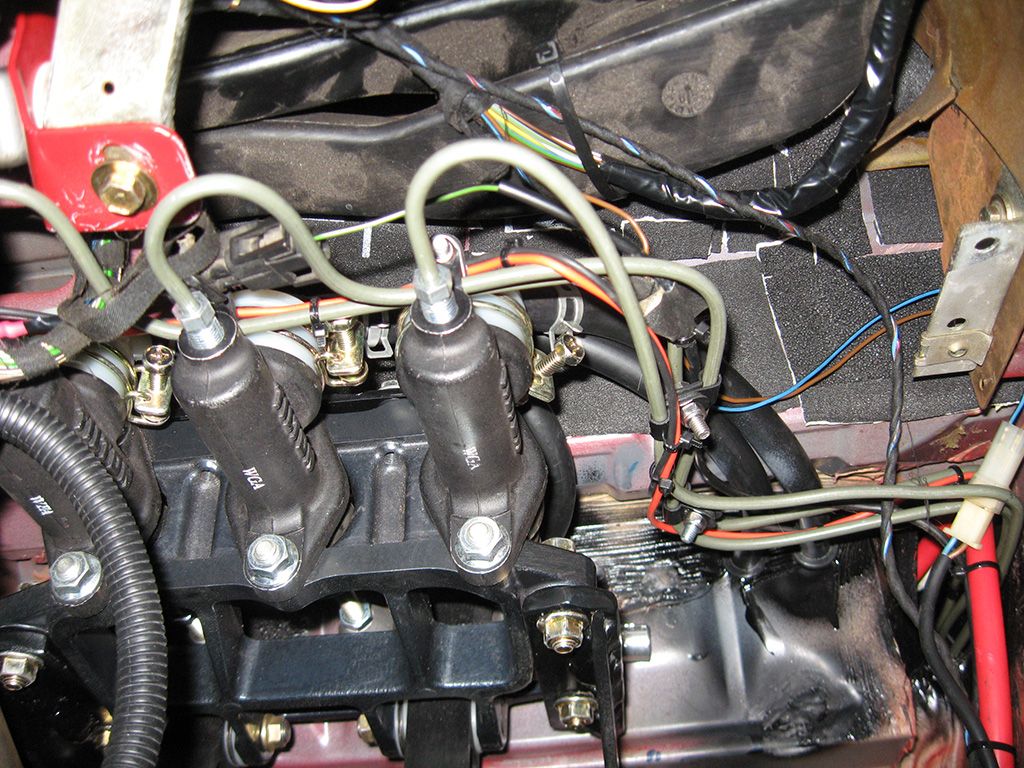

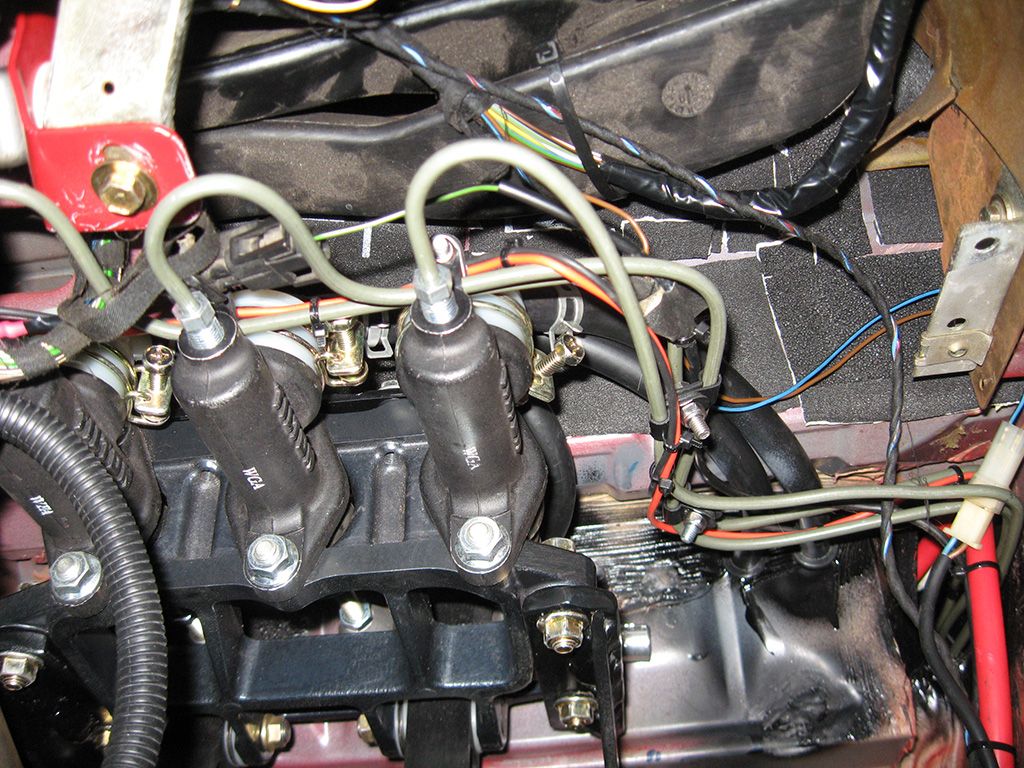

Might look a little messy underneath with all those wires and stuff, plus a few little tweaks I had to make in the lines to get them to line up with the saddles so i could fix the lines solid against the chassis, but here is what I mean below. The sharp bends coming out of the masters, I could bend them by hand. Difficult to do that when it's too stiff.

or from the top without the mess of wiring tied to the lines.

Brake line is pretty cheap all things considering, all the flares can be reused, so if you make something up and want to change it later, even if the brake line is too short to reuse elsewhere, you can reuse the flare nuts easy enough.

Running new lines is real easy if you get a decent quality brake tube. Some are just way too hard an inflexible, makes it really difficult to manipulate even with benders. The good stuff you can pretty much bend by hand, makes everything really easy.

Fronts were simple, just used a new T piece, one outlet runs to the master, then one side each to the caliper (left and right). Seeing as the master is on this side of the car, I didn't bother removing all the lines for the calipers to reposition them on the other side of the car near the pedal box. Just ran a new line from the master across the firewall to the T piece. Easy case of just tweaking the existing lines a little to fit into the T piece perfectly. Mounted it solid against the strut tower with a rivnut. I'll probably remake the caliper lines when I pull the engine next time and run everything real tight against the sheet metal as I want to try and locate the power steering reservoir and possibly dry sump reservoir behind the tower in (thinking of maybe relocating the fuse box), but for the time being, it works flawlessly. Also seen in the pic is the new line to the rear brakes. Runs from the master, through an adjustable proportioning valve, then joins up with the existing brake line running to the rear (where the original valve used to sit). When I remove the lines again im going to use flare nuts for the rear which have a notch cut into them to locate them with a clip, so I can position it back through the hole where the valve used to sit.

It's all neat and out of the way, can't even see it when you open the engine bay. It all runs across the firewall and down just below the C101 plug.

Might look a little messy underneath with all those wires and stuff, plus a few little tweaks I had to make in the lines to get them to line up with the saddles so i could fix the lines solid against the chassis, but here is what I mean below. The sharp bends coming out of the masters, I could bend them by hand. Difficult to do that when it's too stiff.

or from the top without the mess of wiring tied to the lines.

Brake line is pretty cheap all things considering, all the flares can be reused, so if you make something up and want to change it later, even if the brake line is too short to reuse elsewhere, you can reuse the flare nuts easy enough.

Comment