;d

[ATTACH]115407[/ATTACH]

Project Snow White (LM4 Swap)

Collapse

X

-

-

What harness are you running? I had a very similar issue with the IAC where it would hold rpms and then lower back down (it was a cheap chinese IAC) I got a new one from autozone and now it doesn't hold rpms but it also won't idle so I think it just needs to get back to the tuner. I would buy another IAC from somewhere locally so you can take it back if it doesn't work. As far as tach the only thing I have seen online is switch the outer wires on your cam sensor (it is a three wire plug) hope you get your issues figured out. I am so frustrated with mine that I haven't touched it in monthsLeave a comment:

-

Having some tuning/running issues. Hopefully someone in here has experienced the same thing.

I am having two issues:

1. The engine fires right up but almost immediately revs high and gives the impression it's going to "run away" so we shut it off. It appeared as though the IAC is not working and is stuck wide open. I pulled the IAC out and moved it by hand, placed it back in the TB and it stayed exactly where I had moved it by hand.

We restarted the engine and I put my finger over the IAC port in the TB and controlled the Idle with my finger...engine ran great. I checked the wiring to the IAC and determined I had pinned the connector backwards. I corrected the wiring and tried again, nothing. IAC still won't move. Thinking I fried the IAC, I bought a new one. Same results - no movement.

Any Ideas?

2. Issue number 2 - I have no tach signal from the ECM. My aftermarket tach wasn't working and I thought I needed to boost the signal. Last night while we were troubleshooting the IAC we noticed that HP tuners wasn't reading a signal either.Leave a comment:

-

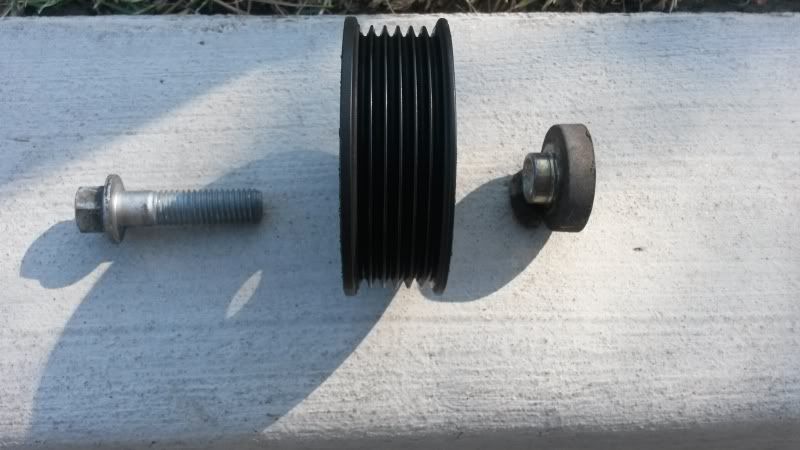

IIRC my idler (I had it laying around) came with a stepped spacer. It looked something like this

Leave a comment:

-

The trick now would be to space the idler out to match the rest of the pulleys. The 1/4" plate takes some planning. What did you use for the fixed pulley in place of the original idler?Leave a comment:

-

I'm running the same accessories as you and my belt setup is identical to this one here. Figured the idler was worth the peace of mind.

Leave a comment:

-

I thought so too but I copied this routing.

I found the guy who's engine was pictured and he said he had been running several years with no issues. I also talked to one other guy on LS1 who ran his belt the same way and didn't have any trouble with it slipping. We'll see. If I have problems I guess it's back to the drawing board.

Here is another post with similar routing

Conversions & Swaps - Alternator / waterpump only setup / belt number - I just got done isntalling mine. I used a 53 6 rib belt. I cant remember which member this car belongs to but it was the picture i went off of when i set mine up. Stock fbody alternator in factory location. Stock tensioner attached to waterpump in...Leave a comment:

-

U need an idler between the water pump and alternator. You have very little belt wrap on the pump there.Leave a comment:

-

Down to a very short list to get her on the road.

1. Leaky TOB fitting - FIXED - Pulled the engine Sunday and installed it Monday and Tuesday.

2. Tune - Scheduled for Tuesday next week

3. Seat and belt installation - will do that tonight or tomorrow

4. Alignment and Tires - scheduled for the same time of the tune

The whole car was being done on a rat rod budget so why stop with the hood? I had a parts car with a semi decent hood (not so good that I felt bad about cutting it up) and I pulled it off and made it fit the engine. I still have the original white hood for the car and will eventually look at doing something with fiberglass. I'll wash the car and throw a coat of matt clear on the hood and call it a day.

Leave a comment:

-

You know, I didn't even look at that....

Edit: I started to look at it and was considering re-doing the bars but after doing some research I am okay with it. Kirkracing makes SCCA approved bolt in cages that attach to the wheel wells in almost the exact location. Looking through pictures of SCCA cages for both e30's and e36's there are lots of examples of the cages welded to the wells. The main load in a roll over is on the hoop; the down bars are to keep the hoop upright and the spreader plates keep the tube from punching/ripping through the sheet metal.

The long term goal of the car will be to modify the shock towers to accept full coil overs and then add bracing down to the differential mount. At some point in the distant future I'll add the components for a full cage but since this will be street driven, I'll wait. Last thing I want to do is wear a helmet and knee pads to drive to work. :)

Since the car will be 99% street (for the time being), I was more concerned with a solid anchor point for the shoulder harnesses.Last edited by sgtskid; 05-12-2017, 12:13 PM.Leave a comment:

-

The wheel house is a really bad place to anchor a cage... there's no structure there.

The wheel house will fold like origami if that bar takes a hit in a rollover.Leave a comment:

-

[ATTACH]114143[/ATTACH]

[ATTACH]114144[/ATTACH]

[ATTACH]114145[/ATTACH]Leave a comment:

Leave a comment: