I get what your sayin. But what diameter pvc would I need to be strong enough?

Roll Bar

Collapse

X

-

Okay. Sounds good. Thanks for the help.

I'll definately keep that in mind.

But I'm kinda stuck on how to bend the pvc? Use angle connectors?1990 Alpinweiss 325i - secret 500whp buildOriginally posted by audiquattrotbimmers b4 b*tches....remember that.

2000 Audi S4 B5 Laser Red

1990 Nissan 240sx - Drift Missile

2006 CBR600RR

Comment

-

me and stephen used angle connectors SOLEY FOR MOCK UP, for final roll bar assembly. you need to heat the pvc piping up to 345* C to melt the plastic but avoid ruining the molecular structural integrity of the pvc. this is key. you need to get a laser temperature gauge to make sure you get it at the right time. otherwise you're back to square one.Comment

-

Fast life fuck slow..Low life for life

Let the mix flow..Let the night flow

I'm so gone ✗ ♥ OComment

-

Impresive......sigpic

1986 "C2 2.7 Alpina" Sedan

1987 325ic Black Vert

1986 327i Red Track Car RIP 10/10/10

1989 325is Henna S50 track car SOLD

Transaction feedback here please!!

http://www.r3vlimited.com/board/showthread.php?t=170548Comment

-

When I did mine, I used that spray foam to insulate and secure the pipes. No squeaks or anything, and its solid. Shit it impressed the hell out of those dumbass d-bags at the track. They all begged me to take out their heavy steal cages and replace them with the lightweight PVC cages. This is some cutting edge shit right here.sigpicComment

-

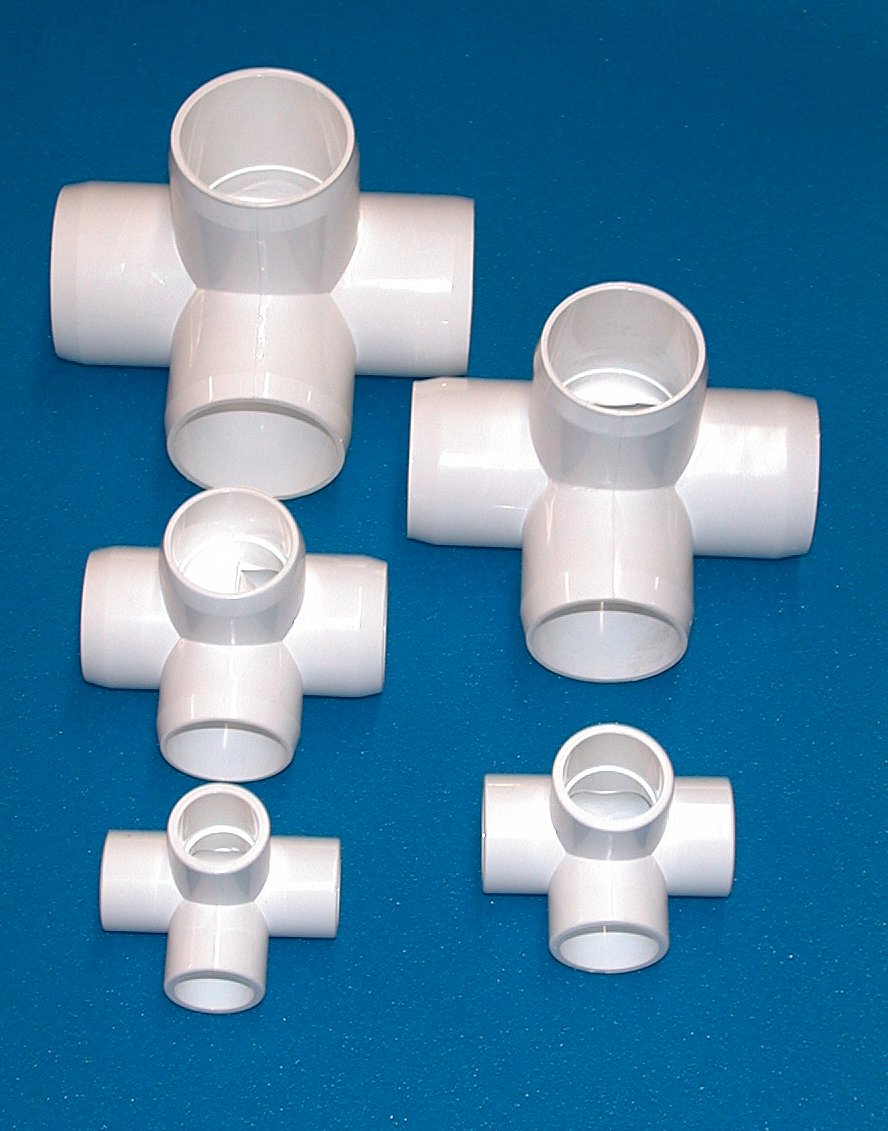

I like to use these connectors at the joints on the main hoop. That way, if you ever decide to go with a full cage, you can simply add on without taking apart the old roll bar.

Comment

Comment