Hi all,

Mat based in Mansfield, England and this is my 1990 E30 320i SE, 76k miles, no rust and still on its original exhaust :-) The car is completely stock apart from I have upgraded the alloys from 14 to 15 inch, a Blaupunkt CD player.

I did an absolute ton of maintenance on the car over the three week Christmas holiday (and finally resolved a long standing hard start issue hurrah!) and took lots of pictures so thought I would pull them all together in the introduction post:-)

So starting with some time of work, first up was a set of genuine 15inch Euroweave BBS alloys which have just had shot blasted and powder coated.

The 14’s which were on the car had tyres which were all cracking and I prefer the wider 7j offset of the 15’s which also had new tyres on so decided to swap them over… hanging onto the 14’s though.

Really pleased with how they look.

Next up the bonnet sound insulation had perished and was falling off into the engine bay, I wanted to keep it original so managed to track down a new OEM set from a company in Germany, PartWorks GmbH.

The old foam came off quite easy but the adhesive backing was a nightmare. I bought some Gtechniq Glue & Tar remover and it worked an absolute treat, taking it right back to shiny clean white paint.

New insulation installed, went on fantastic following all the contours.

Windscreen and headlight washer bottles had 33 years of limescale and were looking very discoloured…

a couple of hours of scrubbing, dishwasher tablets, bleach and soapy water and they were looking like new!

Foolishly I didn’t take a before shot of the engine bay but I spent a full day cleaning, polishing, wiping and treating all the plastics. Looks much better but when it gets garaged again next winter I’m going to do a full engine bay detail.

Next up, the car came with a Sony pop off front stereo which didn’t really fit with the era of the car so I removed it.

After lots of Gumtree and EBay trawling I found this lovely Blaupunkt unit which has the classic removable credit card security system. Sounds fantastic!

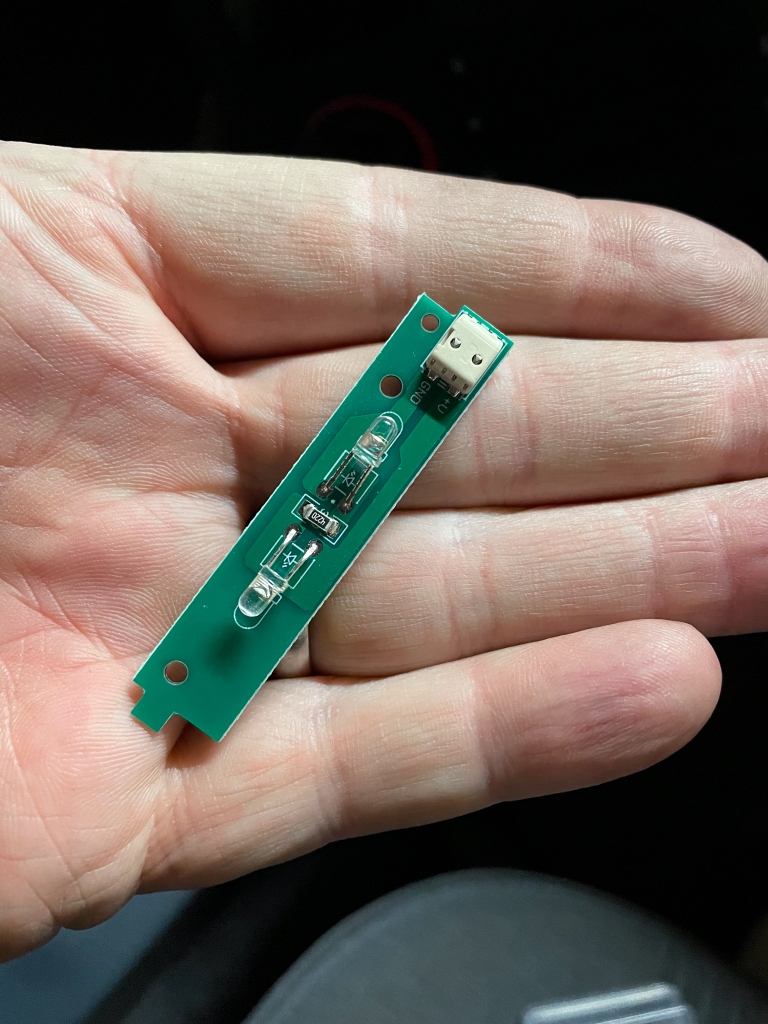

The car came with a 13 button computer installed but unfortunately it wasn’t working. A bit of research unveiled a common issue with the light bar behind the LCD screen which uses traditional bulbs which obviously 30 years down the line go pop.

Thankfully, some genius has developed an LED version which fits perfectly. Its a bit of a faff to get at the computer as I had to remove the full heater dash trim but I got there in the end and after swapping the light strip its all working like new!

The central locking wasn’t working, more online research and it looked likely to be either a live red loop wire which runs through the door or water ingress in the door harness plug.

I unscrewed the speaker and pulled the central locking harness from the space near the pedal footwell and everything looked perfect, no rust, no moisture, wiring like new so next step was the door plug, and what do you know!

The only pin that had a tiny bit of green corrosion was the central locking red wire pin! Some WD40 white lightening, plugged the harness back in and the central locking sprang into life… hurrah!

Next up some external cosmetics…

The exterior trim was a little faded, not bad but not like new so I did a lot of research on some detailing forums and everyone was raving about C4, its a permanent trim restorer.

Its certainly not cheap and comes in a tiny 15m vile but after trying it on the front grill I can see why its so popular with the professionals and went on to do the whole car… just so you can see, right side treated left side original!

I wasn’t to keen on doing a full cut and polish as I don’t have a depth gauge but after asking a few detailers they recommended using some Bilt Hamber Polish which has a very gentle cut but is amazing for deoxidisation of old paint bringing back the colour.

Amazing stuff, you could see it go from a slight yellow tint to bright Alpine white with barely any paint on the pad. The paintwork now looks fantastic, rich deep whites which I finished off with some Auto Finesse Polish.

Onto the mechanics

I decided to dive in and fit a new timing belt, water pump, temp sensors and auxiliary belts, spark plugs, oil pressure sensor, oil and filter change, new Bosch battery and a coolant flush... amazingly Euro Carparts had it all in stock for next day collection!

But before I started all that there were a few other issues I wanted to tackle.

Main one I wanted to sort out was a hard start issue. When the engines cold it needed around 10 seconds of cranking and some accelerator pumping before its burst into life, it then ran rich. Once warm, restarts were quicker but still needed some accelerator action to get it going which is not how it should be.

Second thing, oil leaks... The M20 engine is renown as a leaky unit but the block had what looked like 30 years of oil blown all around it and was a bit of a mess as well as giving me small but regular drips on the floor.

I started by cleaning everything down, around 20 cans of brake cleaner and degreaser later it was looking much better, shiny and clean.

I then added some UV oil dye and let the engine tick over for half an hour, turned the garage light off and the UV torch on and it was clear where the issues were... leaking from the rocker cover, front cam seal and the oil pressure sensor... so all three were added to the parts order.

Next issue, the temperature gauge barely got out of the blue even on long runs, it could be the thermostat or the brown temp sensor plug which feeds data to the cluster... added them both and the blue ECU temp sensor to the order as well.

So, first up, dismantle the front of the engine... distributor cap off, leads out, radiator out, fan off with the special clutch tools, power steering, air con and alternator dropped and belts removed. Timing covers taken off top and bottom, crank pulley (which needed some heat on the bolts to crack!) removed along with cam sensor and timing wheel followed by the old water pump taken and a flood of coolant.

I could then take off the old timing belt and tensioner, clean everything up, and fit a new front cam seal. The belt had only done 20,000 miles but was 10 years old so definitely ready!

Perfect opportunity to get everything cleaned up

Front cam gear removed, followed by cam seal which was replaced with a new one and refitted.

New belt and tensioner on and manually crank the engine to check the TDC markings matched and tension the belt before locking the tensioner off... all good! It was just then a matter of re-assembling everything piece by piece, torquing it all up as per the Haynes guide and fitting the new aux belts.

Then I replaced the oil pressure sensor, old sensor was a 22mm, new one a 24mm just to keep me on my toes haha!

Both temp sensors replaced up top and then dismantled the thermostat housing and fitted a new one, old one seemed very stiff so had probably been stuck open causing the temperature gauge issue and the car to run a rich.

Final job before refitting all the hoses was cleaning up all the connecting points to remove coolant corrosion and then onto the rocker cover gasket, replaced it along with the four rubber D plugs. So that was all the leaks addressed now!

Ten litres of new BMW coolant added and then it was time to fire it up and see if everything worked. Doesn't matter how many times I do a new timing belt its still a nervous key turn haha! Thankfully it was perfect, no coolant leaks and no squeaky auxiliary belts but still the hard start issue persisted.

Next up was an oil, filter and spark plugs change and left her ticking over for an hour... no oil leaks, no coolant leaks and sounds as sweet as a nut!

Not sure if was the cold weather or the hard start issue draining it with the excessive cranking but the battery didn't seem to be too good. Replaced it with a new Bosh 096 whilst I was cleaning up the engine bay.

After all of that the hard start issue still remained. Forums to the rescue, I replaced the fuel filter first... whether it was the problem or not it was definitely ready haha!

Nice new Febi Bilstein filter installed but unfortunately did not fix the issue.

Next I replaced the fuel pump under the back seat and also the fuel pump relay.

Another try of the key and the problem remained. Sad times!

Then I received a message on R3vLimited from a chap who said ''it will be the C191 plug under the intake manifold they ten to suffer from corrosion and its the main link between the injectors and the ECU so causes havoc and all the symptoms described''.

So I removed the intake feed, the tick over valve and worked my way down the the infamous plug. I pulled it apart and whilst there was no obvious corrosion the female side did have a little green casting to the colour of the pin receivers.

I bought a Burr kit and after a blasting of electrical cleaner and some gentle filing of the inside of each pin receiver I put everything back together after spraying some electrical grease inside to stop the problem occurring.

The internals of the tick over valve didn't look like it was spinning easily so I also gave that and the throttle body a good clean with Carb cleaner.

Reassembled everything and... key turn... YES!

Fired right up in a split second with no throttle, no longer running rich and tick over was absolutely solid... I'm so happy!!!! Haha.

Sot thats the car so far, I'll keep this up to date going forward :-)

Comment