I loved the PMC shifter on the Aluminum Monster.

This go-round Im trying to keep it as silky smooth as I can get the OEM feel.

The solid stuff is definitely for the "fun" car and less for the daily car IMO

SLC: 1989 Zinno coupe. Superlight, Super Functional *6spd swap inside*

Collapse

X

-

Yessir. Plan is if I go turbo in the next year or two I will use a Vipec or similar stand alone that is near plug n play on the OBD1 harness

I would have liked to do this and may still someday, but budget was a major constraint. I got the engine, trans, and a few other swap components through a trade deal with a friend so this swap (and everything else I had to buy myself to finish it) was never really planned for or budgeted so I've been doing what I can without spending more than I should to finish it up right. I was always very happy with my fully rebuilt shifter I had on my previous trans setup with a DSSR and Z4 2.5 lever, so I'm hoping this trans will feel just as crisp as the last one did. All in all I will be like $150 and some fab time in this shifter vs $470+ the cost of a dssr for the IRP shifter that I would like to have.I'm a little curious on a build of this level why you did not just go to a body mounted shifter like UUC / BW or the even better elevated tower shifters like CAE / Samsonas?

They are so much more machine like than the carrier mounted shifters.

Just a question, not a dig on the build. Build looks pretty cool so far.Leave a comment:

-

I'm a little curious on a build of this level why you did not just go to a body mounted shifter like UUC / BW or the even better elevated tower shifters like CAE / Samsonas?i test fitted the shift carrier for the 6 speed that needs to be shortened and determined i needed to section out about 1" to line the shifter up in the hole in the tunnel. i did the cutting then had my friend brad (edutechnic) weld it up since i don't have the skills or equipment to weld aluminum yet.

They are so much more machine like than the carrier mounted shifters.

Just a question, not a dig on the build. Build looks pretty cool so far.Leave a comment:

-

yesterday was what will probably be the last 40*+ sunny day here until february, so i took advantage as much as i could. i mocked up a prototype selector rod for the 6 speed trans. i am going to send the mockup to garagistic so they can use it to make me a custom stainless one for the swap. i was planning on modifying my UUC one but i couldn't make myself chop up such a nice piece of hardware.

after finishing the shifter mockup i pulled the engine and trans back out. subframe, strut housings, and trans mount will all be going to get powdercoated soon.

once the engine and trans were back out, i used my roller rear wheels and engine hoist to roll the car out into the driveway. once out there i raised it up and soaked the undercarriage and trans tunnel with degreaser and pressure washed it off. the old engine and trans leaked a fair amount and the sludge and grease underneath was horrible so i'm glad i got it cleaned up. it will be much more pleasant now to clean up the bay, do the final engine and trans install, etc etc.

also i am selling my 325i UUC DSSR. it is posted in the classified section, shoot me a pm if you are interested!

Leave a comment:

-

also, anyone reading this who has done a 24v swap, how did you mount your diagnostic port and engine harness relays? i tried to find mounting brackets on realoem but couldn't find anything. i sold my m20 relay bracket with the engine so i no longer have that and i'd like to mount them somewhere on the passenger side near the firewall. maybe i'll have to hit the junkyard this weekend and see if i can find brackets of some sort.

Didn't browse your thread, if your using m3 covers, has provisions for the relays to sit there, if not, try the fuse box where the auxiliary fuse box is?

Sent from my iPhone using TapatalkLeave a comment:

-

also, anyone reading this who has done a 24v swap, how did you mount your diagnostic port and engine harness relays? i tried to find mounting brackets on realoem but couldn't find anything. i sold my m20 relay bracket with the engine so i no longer have that and i'd like to mount them somewhere on the passenger side near the firewall. maybe i'll have to hit the junkyard this weekend and see if i can find brackets of some sort.Leave a comment:

-

ordered an oil pressure adapter from ebay to accommodate my oil temp and pressure gauge senders. this one is similar to the one bimmerworld sells but i scored it for $27 versus the $100+ pricetag on the bimmerworld piece.

i ordered intake parts this week as well, they should be here soon.

i also laid out my harness on the living room floor and gave it an overhaul over the past two days. the engine and harness came from an auto 325i so i removed all auto trans related wiring, as well as all of the ugly rubber loom and giant plastic thing that covers all of the splices and wiring. the junkyard that pulled the engine also cut the o2 sensor pigtail off so i removed one from my spare harness and spliced it into this one. after everything was trimmed/depinned/labeled to my satisfaction i used self fusing silicone tape to wrap the harness. this tape is strange but works much better than loom or ugly shiny electrical tape. it also seals very well and should last some time. i also have every plug and pigtail labeled so install should be pretty easy when i get to it.

oil pressure adapter:

harness before (with bonus doggo):

harness after:

Leave a comment:

-

-

definitely. this is a donor subframe i picked up from edutechnic, my original one was cracked and beat to shit just from m20 power. with the m50 and potential turbo someday its absolutely mandatory.

i hope so!

ordered an oil pressure adapter for the m50 so i can install my senders for my oil temp and pressure gauges.

also acquired some motul 5w40 to lube up the m50 from a local surplus store. got 5L jugs for only $22 each. i bought all the had haha

and i welded my GC perches on my struts.

next up is test fitting my selector rod and modifying as necessary to fit this trans setup. after finishing the shifter fabrication and testing, i will remove the engine and trans again. i need to fit the front suspension and roll the car out into the driveway so i can degrease and pressure was the engine bay and trans tunnel. then i will finish the removable core support and paint all of the exposed metal in the bay. at the same time i will send out the subframe, struts, and transmission brace to be powdercoated.Leave a comment:

-

lookin good! those subframe reinforcements seem like a super good ideaLeave a comment:

-

ordered ground controls during their black friday sale, got those earlier this week but they forgot my o rings for the front adjuster sleeves so i'm still waiting for those before i can get going with the coilover install.

i test fitted the shift carrier for the 6 speed that needs to be shortened and determined i needed to section out about 1" to line the shifter up in the hole in the tunnel. i did the cutting then had my friend brad (edutechnic) weld it up since i don't have the skills or equipment to weld aluminum yet.

Untitled by mitch allen, on Flickr

Untitled by mitch allen, on Flickr

Untitled by mitch allen, on Flickr

Untitled by mitch allen, on Flickr

Untitled by mitch allen, on Flickr

Untitled by mitch allen, on Flickr

Leave a comment:

-

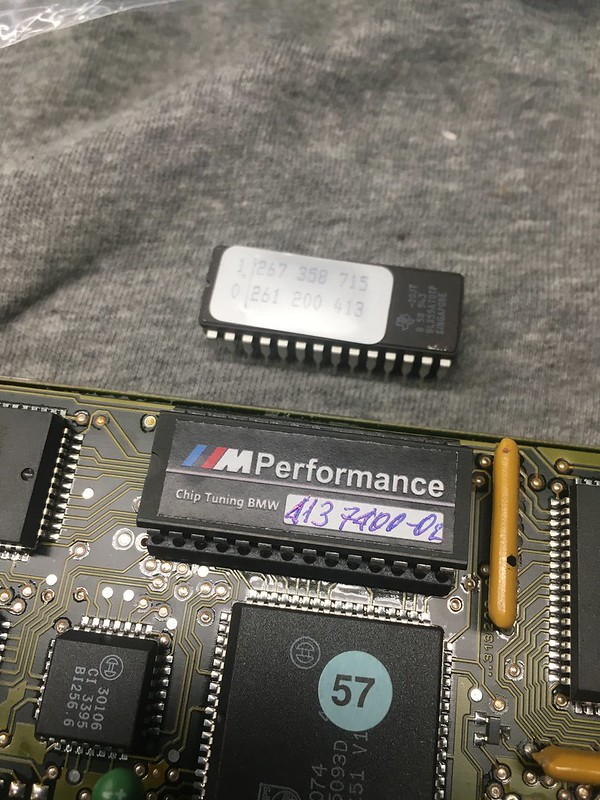

got my ultra dope ebay chip in. this is also good because it bypasses ews and my ecu is a silver label 413.

Untitled by mitch allen, on Flickr

Untitled by mitch allen, on Flickr

Untitled by mitch allen, on Flickr

Untitled by mitch allen, on Flickr

Leave a comment:

Leave a comment: