Congrats on getting the engine in.

I'm sure they'll be fine but if you find the condor mounts too harsh I personally run E46 M3 mounts upside down with the locating tabs removed. I've found them much less prone to sag and much stiffer than the usual E28 combination without adding any noticeable NVH.

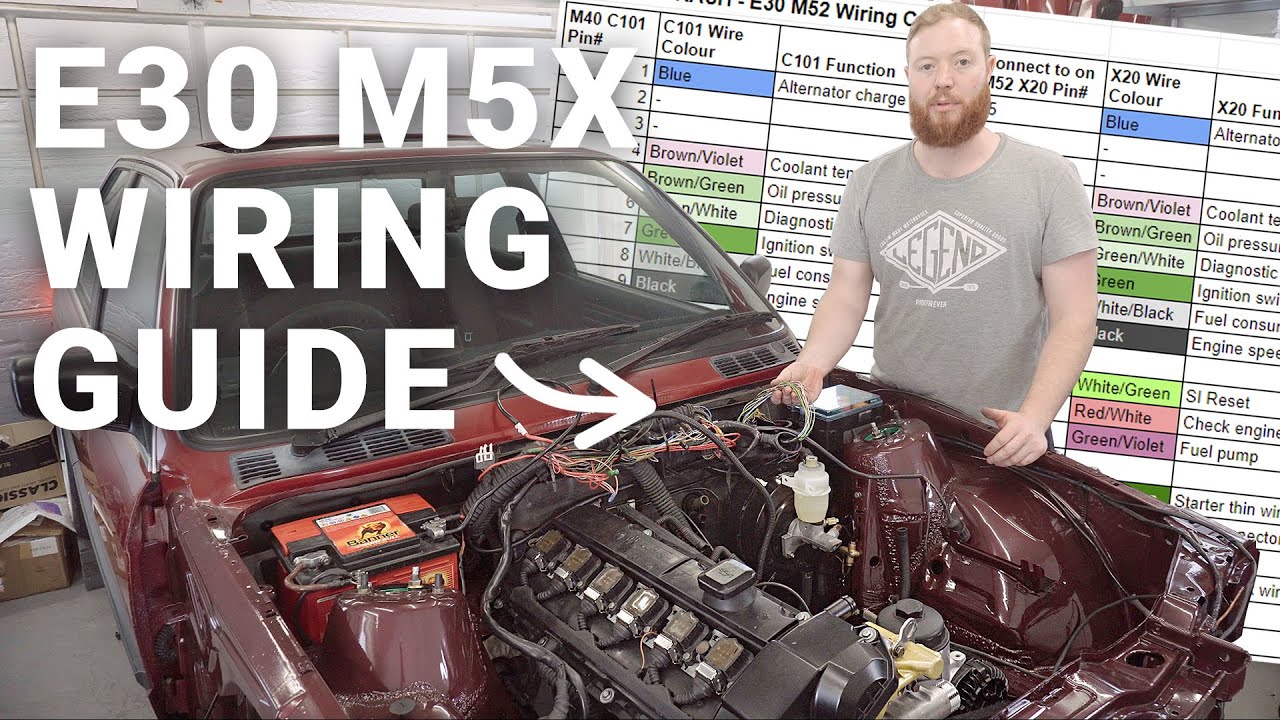

Wiring is quite simple really, I would highly recommend buying the correct c101 pins and an appropriate de-pin (FalkMFG) and crimp tool and wire in a C101 properly.

You can disassemble the ECU connector which makes slipping it through the firewall a breeze and Haltech stock a firewall grommet that fits the e30 really well if your stock one is damaged.

Remove all the plastics from the E36 harness (if it was an auto harness you can strip all the auto wires out) and with some careful placement it should all fit inside the E30 318i harness cover, add an M3 firewall trim panel.

Hopefully you are using an MS41 ECU, removing EWS is very simple and everything you could possibly need to do it is documented here https://sites.google.com/site/openms41/home.

I'm sure they'll be fine but if you find the condor mounts too harsh I personally run E46 M3 mounts upside down with the locating tabs removed. I've found them much less prone to sag and much stiffer than the usual E28 combination without adding any noticeable NVH.

Wiring is quite simple really, I would highly recommend buying the correct c101 pins and an appropriate de-pin (FalkMFG) and crimp tool and wire in a C101 properly.

You can disassemble the ECU connector which makes slipping it through the firewall a breeze and Haltech stock a firewall grommet that fits the e30 really well if your stock one is damaged.

Remove all the plastics from the E36 harness (if it was an auto harness you can strip all the auto wires out) and with some careful placement it should all fit inside the E30 318i harness cover, add an M3 firewall trim panel.

Hopefully you are using an MS41 ECU, removing EWS is very simple and everything you could possibly need to do it is documented here https://sites.google.com/site/openms41/home.

Comment