As noted in my E30 build, I've got a little side project going on. Basically reshelling an E39 after the wife's daily got destroyed.

Back in 2017 we decided we needed a sedan for when family visits (I had a reg cab truck, the wife an Accord coupe) and I looked around for something cheap that needed some work but was relatively simple and inexpensive to fix. A non-running, 1998 BMW 528i with 220k and precisely zero working parts is none of those things. Except cheap. I gave the guy $950 and limped the thing 2 blocks home on a failing alternator and just about coasted it into the apartment car park before it died.

Over 5 years, she got ALL the love. Full chassis overhaul with all new Lemforder & Sachs parts, she rode factory fresh. Every single mechanical issue was fixed. And then the headgasket threw in the towel at 245k. No cooling system failure, the gasket just perished between cylinders 3 & 4. So the engine was torn down to the rotating assembly, cylinder head refreshed, new timing guides & tensioner, evry gasket & hose has been replaced. Replaced all the window regulators, replaced the sunroof cassette, reupholstered headliner & pillars... It was like driving one fresh off the showroom and it was magnificent. And drive it we did, with the wife daily driving it all the way up to 270k without a worry.

When something you've put so much effort into is destroyed by a red light runner not paying attention, it sucks pretty hard.

Luckily the old Bavarian barge took it like a champ and my wife was able to walk away with only minor bruises. She saw the other driver coming, and was able to punch it when she realised they weren't stopping and mostly cleared the intersection. The other car blew a red on a 55mph road and went into the left rear of the E39 without even dabbing the brakes. Wifey did a full 270 on the spot, the trunk has been pushed out the other side of the car, but the rear window aperture and door jams are all square, all airbags deployed correctly.

The car was immediately and unceremoniously dumped outside my workshop to save it from loitering in a salvage yard. I popped it up on stands and assessed the damage.

The shell is obviously toast. The impact was pretty severe as it's Pringled the rear wheel, bent the shock and either pulled the balljoints out of the control arm or torn the tabs off the upright itself. It also burst the spherical balljoint out of the upright and the integral link. I imagine the subframe is buggered too.

I was more shocked to find the front right corner damage. I can only surmise that the weight of the car was forced upon this corner as it spun, as there was no external impact to this corner. Similarly, the balljoint was torn from the tie rod and one of the control arms snapped, punching a big gouge in the rim

The crash was back in Oct '22 and it took a few weeks of banging my head against a wall to get any sort of money out of the insurance company. Since then, I've looked at a number of E39s and they've all been hilariously overpriced for the condition and nothing close to being worthy of rebuilding to a similar standard. However... last week I called the guys who do all my tires & alignments (and a most excellent job they do too) as I knew they had a very mint E39 I was sure they wouldn't part with, but they did have one of their 3rd rung shop cars they said I was free to take a look at. Well, it's not pretty and everything leaks and the windows don't work and it makes some rather unnerving vibrations from the right rear. But it's a pretty tidy shell without the normal rot (that I can see...) and the price was more than acceptable. So, time to do it all over again!

It belonged to a customer who was tired of fixing it and so they acquired it, did the minimum to keep it moving along as a spare car and runaround for the shop. Said they put tires on it and those are dated 2012 so it's had a life as a shop car, as the interior shows...

It does have the beautiful anthracite wood trim which is a bonus

Most importantly, it's an 03/97 build car which means it has the same single VANOS, cable operated throttle M52B28 as our old car. Just quite a bit grubbier...

So first job is to yank that out to make way for the rebuilt engine from the old car. This one can be rebuilt for an E30 of some sort at a later date. Then I'll set to work doing a full chassis refresh again. It's so worth the money in these E39's, they ride like nothing else on a cruise. I stuck with stock ride height, non-Sport OEM Sachs dampers and 225/60R15 Cooper tires. Puts every modern rental I get on work trips to shame.

I've been pretty down over the whole situation since the accident, but now feel reinvigorated with a decent shell in my hands. I'll try to keep chipping away at the E30 but will be going full steam ahead on the E39 to get it back into daily rotation for about May when they stop salting the roads in Indiana. I'll reference progress in this thread, but probably log the rebuild as it's own project too, in case anyone is interested. Can't wait to drive a fresh one again!

For now, it's just doing E39 things to my garage floor...

Back in 2017 we decided we needed a sedan for when family visits (I had a reg cab truck, the wife an Accord coupe) and I looked around for something cheap that needed some work but was relatively simple and inexpensive to fix. A non-running, 1998 BMW 528i with 220k and precisely zero working parts is none of those things. Except cheap. I gave the guy $950 and limped the thing 2 blocks home on a failing alternator and just about coasted it into the apartment car park before it died.

Over 5 years, she got ALL the love. Full chassis overhaul with all new Lemforder & Sachs parts, she rode factory fresh. Every single mechanical issue was fixed. And then the headgasket threw in the towel at 245k. No cooling system failure, the gasket just perished between cylinders 3 & 4. So the engine was torn down to the rotating assembly, cylinder head refreshed, new timing guides & tensioner, evry gasket & hose has been replaced. Replaced all the window regulators, replaced the sunroof cassette, reupholstered headliner & pillars... It was like driving one fresh off the showroom and it was magnificent. And drive it we did, with the wife daily driving it all the way up to 270k without a worry.

When something you've put so much effort into is destroyed by a red light runner not paying attention, it sucks pretty hard.

Luckily the old Bavarian barge took it like a champ and my wife was able to walk away with only minor bruises. She saw the other driver coming, and was able to punch it when she realised they weren't stopping and mostly cleared the intersection. The other car blew a red on a 55mph road and went into the left rear of the E39 without even dabbing the brakes. Wifey did a full 270 on the spot, the trunk has been pushed out the other side of the car, but the rear window aperture and door jams are all square, all airbags deployed correctly.

The car was immediately and unceremoniously dumped outside my workshop to save it from loitering in a salvage yard. I popped it up on stands and assessed the damage.

The shell is obviously toast. The impact was pretty severe as it's Pringled the rear wheel, bent the shock and either pulled the balljoints out of the control arm or torn the tabs off the upright itself. It also burst the spherical balljoint out of the upright and the integral link. I imagine the subframe is buggered too.

I was more shocked to find the front right corner damage. I can only surmise that the weight of the car was forced upon this corner as it spun, as there was no external impact to this corner. Similarly, the balljoint was torn from the tie rod and one of the control arms snapped, punching a big gouge in the rim

The crash was back in Oct '22 and it took a few weeks of banging my head against a wall to get any sort of money out of the insurance company. Since then, I've looked at a number of E39s and they've all been hilariously overpriced for the condition and nothing close to being worthy of rebuilding to a similar standard. However... last week I called the guys who do all my tires & alignments (and a most excellent job they do too) as I knew they had a very mint E39 I was sure they wouldn't part with, but they did have one of their 3rd rung shop cars they said I was free to take a look at. Well, it's not pretty and everything leaks and the windows don't work and it makes some rather unnerving vibrations from the right rear. But it's a pretty tidy shell without the normal rot (that I can see...) and the price was more than acceptable. So, time to do it all over again!

It belonged to a customer who was tired of fixing it and so they acquired it, did the minimum to keep it moving along as a spare car and runaround for the shop. Said they put tires on it and those are dated 2012 so it's had a life as a shop car, as the interior shows...

It does have the beautiful anthracite wood trim which is a bonus

Most importantly, it's an 03/97 build car which means it has the same single VANOS, cable operated throttle M52B28 as our old car. Just quite a bit grubbier...

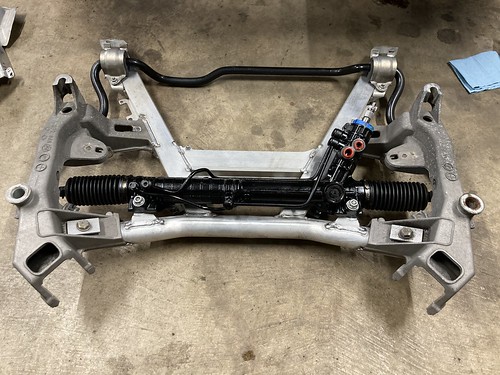

So first job is to yank that out to make way for the rebuilt engine from the old car. This one can be rebuilt for an E30 of some sort at a later date. Then I'll set to work doing a full chassis refresh again. It's so worth the money in these E39's, they ride like nothing else on a cruise. I stuck with stock ride height, non-Sport OEM Sachs dampers and 225/60R15 Cooper tires. Puts every modern rental I get on work trips to shame.

I've been pretty down over the whole situation since the accident, but now feel reinvigorated with a decent shell in my hands. I'll try to keep chipping away at the E30 but will be going full steam ahead on the E39 to get it back into daily rotation for about May when they stop salting the roads in Indiana. I'll reference progress in this thread, but probably log the rebuild as it's own project too, in case anyone is interested. Can't wait to drive a fresh one again!

For now, it's just doing E39 things to my garage floor...

(finished article will appear later

(finished article will appear later

Comment