Thats crazy. Didn't know about that car.

24 Hours of Lemons Contender

Collapse

X

-

Your signature picture has been removed since it contained the Photobucket "upgrade your account" image.

www.gecoils.com

My euro 316 project Transaction Feedback -

Haha ok.

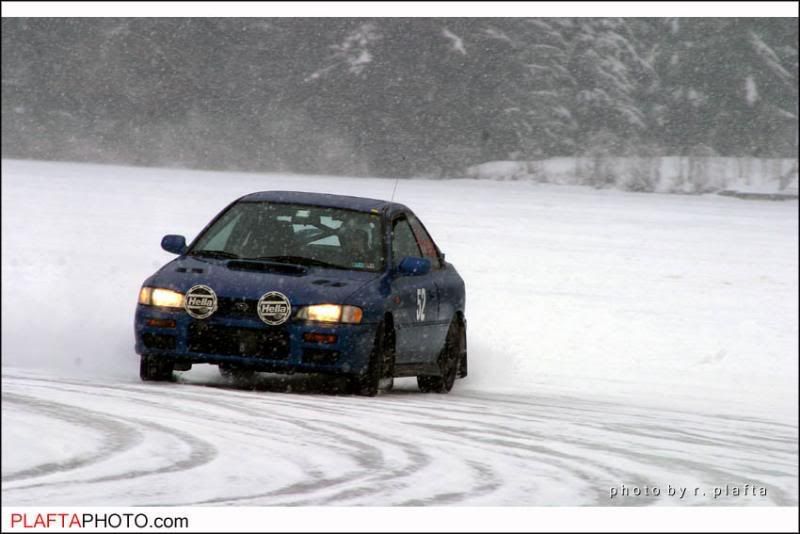

Here it is 1998 Impreza 2.5RS. Blew the original engine at a track day at Summit Point, and swapped in a 2007 WRX Engine. Was rear ended last year a week after my first hillclimb, and I missed the rest of the season. I don't drive it much on the street now, mainly use it for hillclimbs and autocross.

When I bought it.

Destroyed Engine

Engine Swap

Accident

Fixed

Racing

Comment

-

damn. i need to add a swapped 2.5rs to my "must acquire" list ;)

Originally posted by stewie30luvrooo cause i was fixing my chain tensioner and there was a black widow on the radiator so i killed itOriginally posted by JakePwith a coathangerComment

-

-

Lemon cars are the best, we also have an e30 lemons.www.CASTROMOTORSPORT.com

Castro Motorsport

12600 Sherman Way, Unit C

North Hollywood, CA 91605

818-765-3606

Follow Castro's on Facebook:

http://www.facebook.com/pages/Castro...02411516506828

Follow Castro's on Instagram:

http://instagram.com/castromotorsport#

sigpicComment

-

There are a lot of E30 lemons cars, that's why we are trying to be unique. :)

Went and picked up the cage kit last night from S&W Race Cars. It looks well made, but havent' gotten a chance to fit anything up yet.

Does anyone have a picture of the S&W kit installed in their car? I'd like to see exactly where everything ties in. I think the convertible might be a little different with the sill extensions that are on there, but that's nothing a little cutting can't fix.Comment

-

Sorry for the lack of updates recently. Here is a catch up from the last two work days.

November 6, 2010

The day started with removing sound deadening and various interior brackets. Ideally we would have gotten some dry ice, and removed it quickly and easily, but cool outside temperatures and a heavy hammer seemed to be an acceptable substitute.

Next task was replacing the studs for the seats that Tom pounded through the floor. Let this be a lesson to us to not let him have free reign. Tom says, “When you give me a hammer, everything becomes a nail.” Let that be a warning to you if your fingers are ever near his work area.

Hard to beat the alluring glow of a welding picture.

Yeap, seat fits. Now take it back out so we don’t set it on fire.

We then split into a couple groups to work on various parts of the car.

Chuck and Dan tore into the engine to check bearings, dirt and anything else that might bring us to a screeching halt in the race. They were surprised to see just how clean everything really was. It seems like we found a good one. (Sorry no pictures, it was already back together before I was done with my job. Actually we were pretty bad with pictures on the whole this work day.)

Tom worked on facilitating engine installation, by making the radiator support removable. This will allow us easy access for the engine install, and allow us to install the engine and transmission together. Also in the highly unlikely (wink, wink, knock on wood) event of an issue at the race, we should be able to pull everything and not lose too much seat time.

Here is the fruit of his labor.

Jim and Ryan worked on making clearance for the roll cage. There is a lot of extra metal on the convertibles that isn’t on the coupes or sedans. It took a lot of cutting (thankfully we borrowed a friend’s plasma cutter), but they finally had room to mount the plates for the main hoop.

We then took out some frustration on the passenger side inner door sheet metal with the plasma cutter. That’s pointless metal we won’t need.

With the roll hoop mounting plates installed the seat went back in to get a height for the main hoop.

Chuck takes the dummy’s seat and we measure how much we can cut off the hoop. If it wasn’t for his ungainly torso-to-legs ratio, it would be more (Tom isn’t far behind though when it comes to disproportionate torso lengths.)

Then the seat came back out. (See a trend here) Again, we don’t want fires.

Got the hoop tacked in place, and called it a day. We need to cut out some more metal to make welding easier, and get the rest of the cage in place.

November 20, 2010

Started the day by taking the hoop back out and making more room for welding the plates to the frame. Next cut some holes to run the main hoop braces into the trunk.

Chuck then got his hands on the plasma cutter and removed the driver side inner door sheet metal.

Sweet Victory, Part I

Next the team decided the windshield would go. Now we will really have a unique vehicle. A V8 powered BMW 350 Speedster! Unfortunately we didn’t save as much weight as we thought. Seems rollover protection was not a concern in the late 80s. We will be installing Lexan across the front of the rollcage for the race. Weight savings was not the only goal here, as the old arrangement would have created claustrophobic conditions between your forehead and the halo bar of the cage.

Jim and Tom cut the A pillars. (You can see in the top right of the picture where Chuck didn’t want to stop with the plasma cutter.)

Sweet Victory, Part II

Speedster Style, Oh Yeah!!!

Back to work. Now with some breathing room, the main hoop goes back in, and hoop braces are tacked in.

The halo bar is temporarily tacked in to figure out the front braces.

Chuck cleans up the floor where the front brace plates will mount.

Chuck works on the main hoop diagonal, while Jim and Ryan work on the front braces. Some time passes (a lot of time actually), and it starts to really look like a race car.

We still need to install the dash and door bars to finish the cage, then get it fully welded. The door bars will have to be bent NASCAR style to allow room between the door and the seat.

Look for more updates in December.Last edited by camaroz1985; 11-22-2010, 11:34 AM.Comment

-

December 11, 2011

We started by finishing up the cage. We tacked in the dash bar, and set aside tubing to be bent for the door bars. The car should be going to have the cage welded soon, and we are hoping to have it back by the end of the year.

Tom worked on prepping the engine for trial fitting. He removed the headers, and power steering pump.

We are hoping to reuse the headers, but things are looking pretty tight. We might have to trade them for a set of stock manifolds. Tom wanders how you could put them on while in the car (we didn’t tell him that would be his job).

Tom also took the motor mounts off the 302. They were pretty wasted, but we never intended to use them for this project. What we do want is the actual plate that attaches to the engine.

We will salvage this for use in our fabricated mounts.

Meanwhile Chuck and Dan worked on fabricating bumpers. In a perfect world we should have to worry about them, but they are called accidents for a reason. They got the rear welded together and mounted to the car (temporarily).

The front bumper is also complete, but mounting will have to wait until the front end goes on the car. Dan took a much deserved nap (at least in his eyes), and made the team realize that the car might be too comfortable. We are sure that can be fixed.

Ryan and Jim worked on fabricating some sheet metal to close off holes where the a-pillars used to be. We could foresee tools being dropped in there. In the process they set Jim’s coat of fire. It seems some welding splatter landed in his pocket, and began to smolder, which manifested in a flame. Sorry no pictures of the fire, or the work they were doing.

Now, the moment everyone was waiting for, seeing if the engine would fit. Ryan told them all it would fit no problem, after all he had seen it on the internet, and everything there is true. Turns out it was true.

It was known that the oil pan wouldn’t fit, and would need to be modified or replaced. Tom and Jim removed it and made a cardboard and duct tape shield to protect the engines vital bits.

Good thing Harbor Freight is only minutes away, as this would have been a lot harder without the use of a load leveler. The initial fit was pretty good, but there was some interference keeping the engine from setting back as far as possible.

Pull the engine back out and give Tom the hammer he had been salivating over. A few (too many) whacks to the firewall, and the engine went back in. This process was repeated a few times until the final position was decided upon. Things are still tight, but that is to be expected.

The majority of the engine actually sits behind the centerline of the front wheels. That should be very beneficial to maintaining a good weight distribution. This picture was taken standing at the front wheel centerline.

Initial motor mounts were fabricated, and measurements for the oil pan were taken. We plan to modify the existing pan, but if a junkyard trip results in one that works, that would ease leak anxiety experienced by the majority of the team.

Thus concludes official workday #5.

Also, this was Tom’s 48th birthday. I’m sure he couldn’t think of better way to spend it.Comment

-

Nice! It's coming along!

Which race are you entering again? We're prepping our for the Sonoma race in March.

We haven't started on the cage yet, but the engine and suspension is pretty much done.Originally posted by Grueliusand i do not know what bugg brakes are.Comment

-

We are doing the Summit Point race in June. Hoping to be driving by the end of March/beginning of AprilComment

-

February 26, 2011

We have struggled over the last few months to get a lot accomplished. We have had to deal with a welder who, judging from his work has no business with a torch in his hand. Luckily we got the car back before too much damage was done, only to our timeline. The cage was to be finished by January 3. The cage will be fixed/finished by a trusted and qualified welder. He will work on the cage when we aren’t working on the car, and hopefully be done within the next two weeks.

Enough of that, on to the good news. The engine is in the car and off the hoist.

We made engine and transmission mounts using scrap roll cage tubing, angle iron, and parts of the original mounts.

The engine mounts bolt to the original BMW rubber mounts, and use part of the Mustang engine mount to bolt to the engine.

The transmission mount uses existing slots and t-bolts in the BMW frame, and the whole Mustang transmission mount.

When everything is mounted the engine fits under the stock hood, though it is basically touching the hood structure. Some body work may be in order to resolve that.

We did move the engine forward a little from our initial fitting due to oil pan interference. We still had to notch the pan, but not as much, and now there is room for the pickup.

That meant we also had to notch a little bit of the tunnel to allow the shifter to move forward.

After the engine and transmission were mounted, we promptly removed them (not before measuring for our shortened driveshaft). We like putting things together and taking them apart, what can we say. The reason in reality was to allow access to the fire wall. We needed to fill in some holes that won’t be used, and get the pedals from the Mustang into the BMW. A patch panel was made and welded in place. The edges will also have seam sealer smeared on, in the highly (un)likely event that our welds are not perfect. Sorry don’t have pictures of the finished product. Pictures were not a priority at the 15 hour mark of the work day. Here you can see it tacked in place.

Another panel will be made for the large hole in the center. The cowl vents will be left open to the interior of the car for “ventilation”.

At the end of the day, the car is basically going back to welder as it came to us. Doesn’t look like progress is being made, but the next work day should see the engine installed “permanently.” Also the brake and fuel systems should be complete.Comment

-

how much for vert rear seat? and front seats?Comment

-

Comment