I want your seats.

Vert build/m20 stroker

Collapse

X

-

Need a part? PM me.

Get your Bass on. Luke's r3v Boxes are here: http://www.r3vlimited.com/board/showthread.php?t=198123 -

Update:

Port and polished the intake manifold over the weekend. Today I dropped off the M52 crank off at the speed shop for the knifing. I am going to do the pistons myself tomorrow after work.

This is before a good deal of 200grit drum rolls.

Block cleaned

Drying out, then wire brush till it is ready for paint.

Last edited by F34R; 04-12-2011, 03:10 PM.~ Puch Cafe. ~ Do business? feedback ~ Check out my leather company ~

Last edited by F34R; 04-12-2011, 03:10 PM.~ Puch Cafe. ~ Do business? feedback ~ Check out my leather company ~

Instagram: @BWeissLeather

Current cars:

~ '87 325 M30B35 swap

~ '87 535

~ 01 540 Msport 6spd

~ '06 X5 4.8isComment

-

Have you mocked up the rotating assembly in the block yet to check clearances? Or are you just hoping for the best?Comment

-

~ Puch Cafe. ~ Do business? feedback ~ Check out my leather company ~

Instagram: @BWeissLeather

Current cars:

~ '87 325 M30B35 swap

~ '87 535

~ 01 540 Msport 6spd

~ '06 X5 4.8isComment

-

Thanks for the input, I polished the ports to a nice non grooved shine after I "randomly hogged them out". They are bigger & smoother then when they left the factory. It is all about how smooth the air flows.

"decreasing port velocity" would be caused by not smoothing out the air path. Since I have improved this I am not worried. Again, thanks for your input.Last edited by F34R; 04-12-2011, 09:13 PM.~ Puch Cafe. ~ Do business? feedback ~ Check out my leather company ~

Instagram: @BWeissLeather

Current cars:

~ '87 325 M30B35 swap

~ '87 535

~ 01 540 Msport 6spd

~ '06 X5 4.8isComment

-

Comment

-

I used a 100grit drum paper and smoothed the walls even. Some spots were high from removing material, they are not a mirror polish. More like the swirling effect you are talking about. If you look at the intake manifold you can see the swirling I did.

I do have a ball carbide bit, If what you are saying is true then it is no trouble to add those dimples.

Edit: checked the ETA intake mani&head I have and it is close to smooth. So what are these "dimples" you are talking about? I see nothing of these in machine shops that post their work online. I do see swirling, that is what I have.

It is NOT smooth, I used the wrong word. It is even and swirled. So I am going to take my ball tip carbide and make grooves in a slight turn down the intake to make it mix the air/fuel better. I think this is what you are getting at correct? If so thanks, it is a good tip. But from what I have been reading the exhaust side is to be even also with a slight swirling with roughish sand paper. I can feel the swirling with my bare finger tips.

1+ on adding your work if you honestly do this. This is my third time and I have followed lots of builds and spent hours watching DIY videos by pros. I am always down for tips, and the grooves sounds like a great idea in my mind. You want that air coming in towards the end kinda swirled to mix the fuel more even. I thought the sand paper was enough...I am very sure it is on the exhaust side from tons of pictures I have seen. I have not seen very many intake sides.Last edited by F34R; 04-12-2011, 10:58 PM.~ Puch Cafe. ~ Do business? feedback ~ Check out my leather company ~

Instagram: @BWeissLeather

Current cars:

~ '87 325 M30B35 swap

~ '87 535

~ 01 540 Msport 6spd

~ '06 X5 4.8isComment

-

The point is that you actually want turbulent airflow through the ports as opposed to laminar. Smooth surfaces will actually resist airflow more than rough surfaces, and the more turbulent your airflow is (the more swirl or tumble you have) the more it will aid in mixing your intake charge. The only reason builders polish ports is so their customers have something pretty to look at when they get their engines.

Additionally, port matching doesn't really do much (if anything) for airflow. Increasing port diameter could actually hurt your power yield as you are also decreasing velocity and therefore sacrificing mixture uniformity. You want to increase flow while retaining velocity, and it is no simple task.

But really in the end it seems like this is just a fun project for you; you are not going to race the vert, you just want something fun. Properly increasing head flow is no small feat. So don't take this the wrong way--I love this project.paint sucksComment

-

I'm sorry dude but I can almost gaurantee you made the flow worse on that head than it was stock. I've made similar mistakes. you don't want to port match the exhaust, and you definitely don't want to enlarge the intake.

you can work on the bowl, the short side radius, the transition into the valve seat, the roof of the port, and most importantly a good 3 angle cut on the valve seats. Making the ports larger is not the way to go, they are already sufficiently large.

the exhaust side actually can be a mirror finish as you don't have to worry about fuel droplets pooling up on the walls of the port, although it's probably not worth the effort to get a truely mirror finish.Comment

-

The point is that you actually want turbulent airflow through the ports as opposed to laminar. Smooth surfaces will actually resist airflow more than rough surfaces, and the more turbulent your airflow is (the more swirl or tumble you have) the more it will aid in mixing your intake charge. The only reason builders polish ports is so their customers have something pretty to look at when they get their engines.

Additionally, port matching doesn't really do much (if anything) for airflow. Increasing port diameter could actually hurt your power yield as you are also decreasing velocity and therefore sacrificing mixture uniformity. You want to increase flow while retaining velocity, and it is no simple task.

But really in the end it seems like this is just a fun project for you; you are not going to race the vert, you just want something fun. Properly increasing head flow is no small feat. So don't take this the wrong way--I love this project.

^^True info here. Also, almost all airflow gains are in the bowl/seat area, the port runner is kind of along for the ride and dictates velocity. Unless you are reshaping it for a specific reason. Are you going to improve on the crude factory valve seats or back cut your valves? Polishing your exhaust port does help in that it keeps carbon from sticking to the walls and blocking flow. It will be interesting to see the dyno results of your build, keep up the work and have a good time doing it!Comment

-

I did not remove too much from the intake side, I will try and rough it up a bit. I get what you are talking about, a larger intake could affect it like having a bigger straw to blow through. I guess like a spit wad? with the smaller holes it would be forced in faster. I never touched the intake side on the head, it was a perfect match to the gasket.

All I know is I am learning and having fun along the way. This is how you get better correct? :D

The car will be on a dyno mid-late summer. So time will tell if I helped or did next to nothing.

The only racing this car will see is maybe a few SCCA solox events for fun and morons honda kids at red lights. That is about it =)Last edited by F34R; 04-13-2011, 06:16 AM.~ Puch Cafe. ~ Do business? feedback ~ Check out my leather company ~

Instagram: @BWeissLeather

Current cars:

~ '87 325 M30B35 swap

~ '87 535

~ 01 540 Msport 6spd

~ '06 X5 4.8isComment

-

Certainly. ;) I am by no means an expert, but what I can offer is hands on experience porting, reshaping and polishing heads. The BMW engineers obviously had to make a few compromises when designing the M20B25, but from what I had read and seen these compromises are minor.

This may be a shock but, the 325i head flows really well in stock form!

http://speedtalk.com/forum/viewtopic.php?p=83856&sid=3fe13da6c51b11381c3c2ac6 4713b4b8

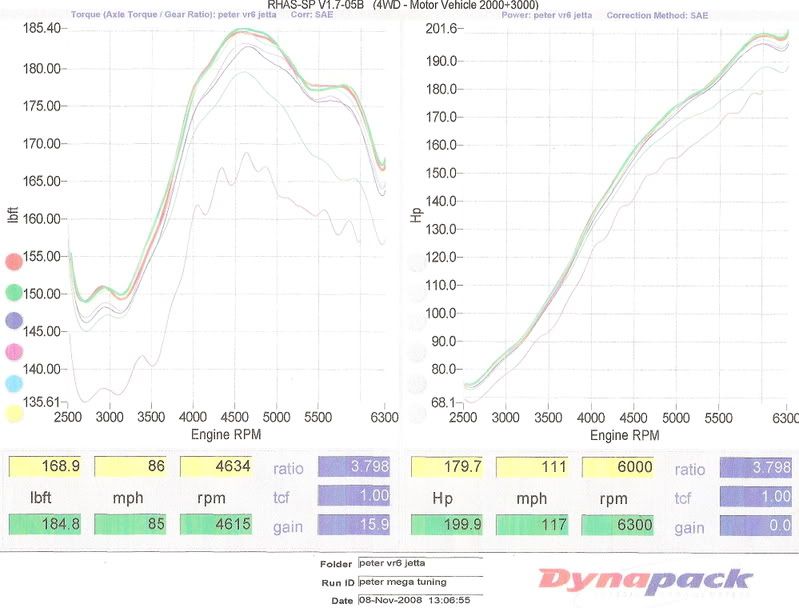

I think the REAL key to unlocking the power hidden in the motor is in the air/fuel tune. I know many people doubt the dyno's that Miller has shown, but there really is alot to a custom tune. Here's the dyno graph from one of my other project cars:

As you can see there was a significant amount of power hidden in just the tune. A custom tune on a Dyno is the only way to truely get all the power out of an engine. Believe it or not I actually decreased the port size by 30% on this head by applying JB weld to build up the port floor.

This is my current build:

http://www.r3vlimited.com/board/showthread.php?t=198800

Its not a performance oriented build so I didn't spend as much time on the head as I have on my cars in the past. However, I am experimenting with the exhaust ports on this motor

I'm sorry but dimpled is the wrong word to use for the ports, sculpted would be better. Here's a Metric Mechanic Head with a "dimpled" combustion chamber. They call it The Hi Turbulence Combustion Chamber

Here is a few examples of what I mean:

The surface is left rough to the touch about 80 grit. You want to keep the pattern as perpendicular to where you think the air will flow.

You have to read this article on the Metric Mechanic Website:

This is taken from that article:

Smooth Surface

Air flowing over a rough surface is greatest simply because the air contacts “touch" the entire surface and this causes maximum resistance.

Rough Surface

Air flowing over a rough surface "touches" mainly the high points. This sets up a stumbling action at the surface disrupting the dormant layer and generating a slight flow increase.

Sculpted Surface

A sculpted surface is one with a repetitive pattern specifically designed to generate rhythmic air turbulence at its surface for maximum air flow. It's the basis for the Surface Turbulence in our Engines and Heads.

Last edited by Paradox; 04-13-2011, 02:43 PM.

Last edited by Paradox; 04-13-2011, 02:43 PM.Comment

-

Shit man, thanks for that! I am glad you posted before I have everything back together. The exhaust side is done right, but I see what you mean on the intake side. I am going to do that tomorrow, I also have 80 grit to finish it off with.~ Puch Cafe. ~ Do business? feedback ~ Check out my leather company ~

Instagram: @BWeissLeather

Current cars:

~ '87 325 M30B35 swap

~ '87 535

~ 01 540 Msport 6spd

~ '06 X5 4.8isComment

Comment