Got a lot going on with the car currently. The front valance, lip, fender, and rear bumper are currently being repainted. I have new euro grills and euro bumper trim as well.

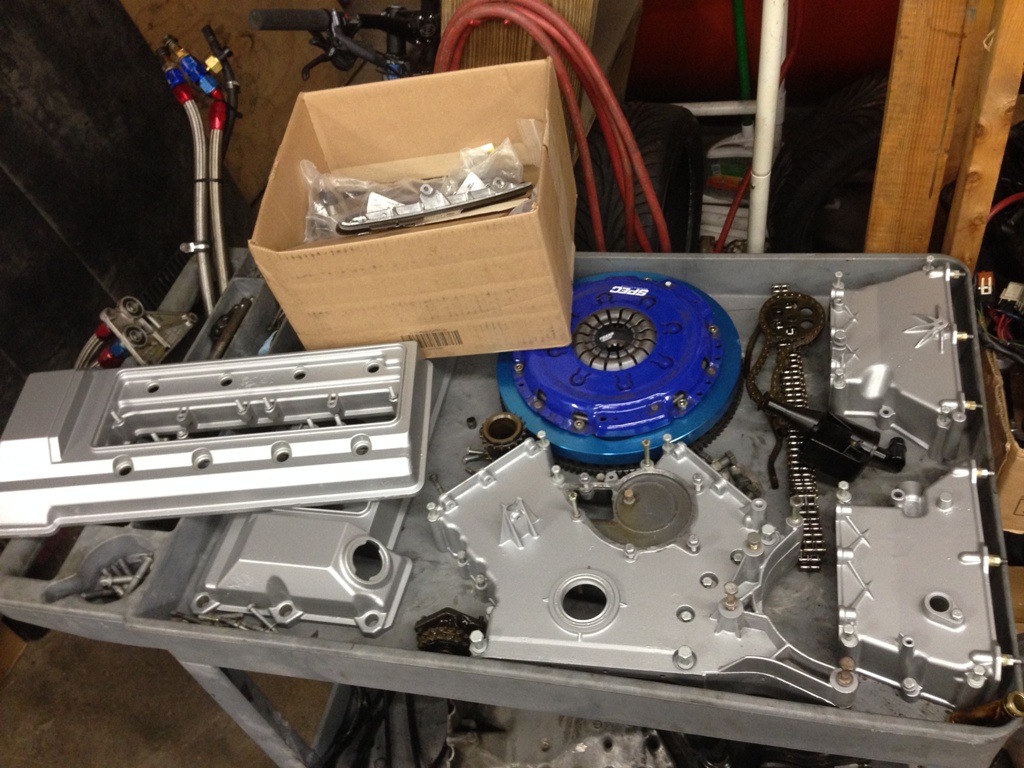

My buddy and I also picked up a 97 540i/6 for $1k. It has slight front end damage. He's going to part it out, I'm keeping the drivetrain.

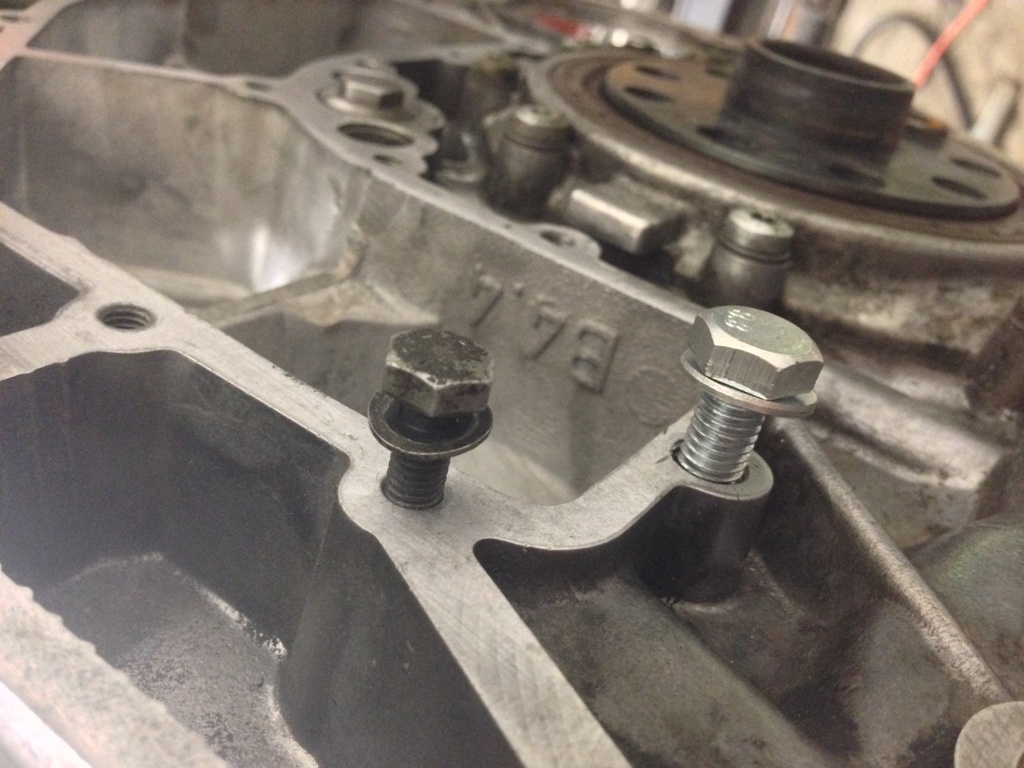

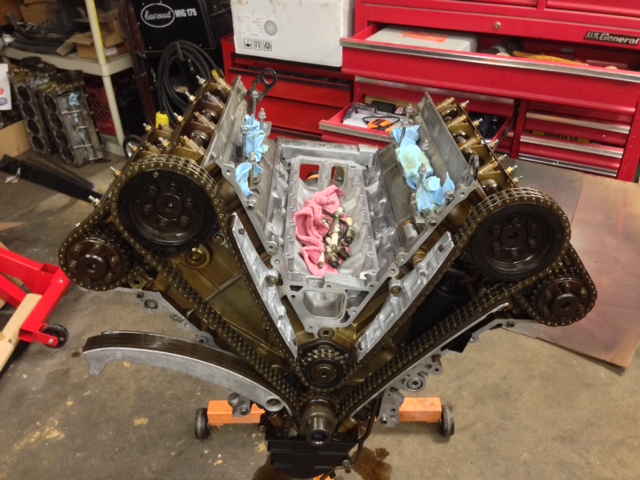

I'm not sure what I'm going to do with it yet. Either build an m60b44, or just swap in the engine as-is after doing an OBD-I conversion. I'd really like to see someone else pave the way with the m60b44 build first. There's 2-3 running, but none really being driven regularly or dyno'd yet. Since I do 15k miles/year, I need this to be reliable. The 11:1 compression ratio kinda scares me. But running an m62 as-is isn't without it's flaws either. The timing guides suck, and the OBD-I conversion method is kinda half assed IMO.

Or I could just keep my perfectly running m60 and throw the 6 speed in with it. Sell the m62 and my five speed and probably come out with a few extra bucks.

My buddy and I also picked up a 97 540i/6 for $1k. It has slight front end damage. He's going to part it out, I'm keeping the drivetrain.

I'm not sure what I'm going to do with it yet. Either build an m60b44, or just swap in the engine as-is after doing an OBD-I conversion. I'd really like to see someone else pave the way with the m60b44 build first. There's 2-3 running, but none really being driven regularly or dyno'd yet. Since I do 15k miles/year, I need this to be reliable. The 11:1 compression ratio kinda scares me. But running an m62 as-is isn't without it's flaws either. The timing guides suck, and the OBD-I conversion method is kinda half assed IMO.

Or I could just keep my perfectly running m60 and throw the 6 speed in with it. Sell the m62 and my five speed and probably come out with a few extra bucks.

DREWLIENTE

DREWLIENTE

Comment