So I'm at the same point with my rear subframe. I have ordered the same bushings. How exactly do you get the whole assembly apart on the trailing arms? And how did you get the trailing arm bushings off?

Ksjdan's 1990 325is Thread - S52 Swap Complete

Collapse

X

-

-

Ive pushed the trailing arm bushings out with a bottle jack a few times. Just put it between the 2 bushings with a socket on the bushing heat the trailing arm a bit with a heat gun and pump the jack they slide right out

The poly ones will go back in with a vice no problemWe're out there in here.

Comment

-

July 11 2014

After a long break, Ive started working on the E30 again few days ago. I halted last time after removing the rear subframe, sandblasting them and putting on a few coat of undercoating. Im sure this doesn't float everyone's boat, and theres some who would recommend powdercoating or painting it red. But I prefer the conservative look of textured mtate black.

Also there is no pictures taken because my phone has been broken all week (fixed now).

I was working on the car for all of the last 3 days, but there's really not much to show for... First thing I did was remove the e-brake cable that was stuck on the chassis tube. I remember trying to get it off for few hours last time, pull it so hard that the car almost fell off the jacks. This time I gave it some heat by torching it for few minutes. Lo and behold, it just slid right off.

Next was the rear wheel bearings, control arm bushings and subframe mounts. The control arm bushings came off very easily with a use of c-clamp and brute force of the impact wrench. The wheel bearing and subframe mount on the other hand, was a biatch and a half.. Im just going to blame it on the lack of proper tools for now. All I really had to work with was a big ass C-clamp rented from Napa and some 3 legged pullers. The biggest issue I faced with all the tools was fitting them on the part.

Stolen Image

The wheel bearing on the trailing arm is deep inside the housing and nearly impossible to reach with even a large 3 or 2 legged pullers. I also tried using the gigantic C-clamp (its a $130 c-clamp so they mean business), but even that couldn't fit around the housing. After going on and off for few days, I gave up.... Went to a harbor freights, bought a wheel bearing removal set.

Without the tool, 2 days of stress and no results. With the tool, 10 minutes of work and done. If you plan on changing the wheel bearing, get the tool!

The rear subframe mounts were a mixed story. While removing the subframe, One of the bushing broke off and the inner piece was off. While the passenger side stayed in and the inner was still held in. The one without the inner turned out to be slightly easier. I noticed a lot of people just burned them off, but it didn't seem civilized (lol) and also it would leave a nasty residue. So I tried fitting a c-clamp (the big ass one), no luck. The bottom side of the bushing is flanged so its needs to be done with a legged pullers...yeah right!

As it shows in RTauto's pic

I tried fitting the legged puller tool, but there wasn't enough space to fit all 3. this is before I went to rent out a 2 legged puller that I didnt own. It didn't work out, so I ended up setting it on fire. After about 15 minutes, I got tired of waiting so I started hitting it with a mallet. This consequently turned the fire off, and punched out the bushing about 0.5 inches. From here I was able to fit a 3 legged tool and slide it off. Easier said than done though. It took about an hour.

After about 15 minutes, I got tired of waiting so I started hitting it with a mallet. This consequently turned the fire off, and punched out the bushing about 0.5 inches. From here I was able to fit a 3 legged tool and slide it off. Easier said than done though. It took about an hour.

The passenger side turned out to be a bigger problem. The subframe bushings also had a stupid design where its nearly impossible to remove the rubber using conventional tools. After numerous hours fiddling with a C-clamp tool and legged pullers, I used the wheel bearing tool (This is about right after I bought it) and got few centimeters out. It was getting late so I called it a day.

So after 3 days, I was able to knock out trailing arm bushings, remove 2 wheel bearings and one subframe mount. Stressful week and slow progress, but at least now I know what to do with the crazy BMW bearings and bushings. After I get the bushings and bearings done, Ill re-seal the diff, put the rear end together and start moving the S52! :DComment

-

So stoked to start working on this bad boy again man. I've been hella busy with my own project though. I'm in the middle of swapping my E30 steering rack with an E36 rack that we I found at our local Pull-A-Part. Once I'm finished with the swap though, I'll swing on down as often as possible to help you out brother! It's really awesome that you're documenting all of the work you've been putting into this old girl. Seeing this thread for the first time has really got me wanting to finish my project this very second and give you a helping hand!Comment

-

:up:So stoked to start working on this bad boy again man. I've been hella busy with my own project though. I'm in the middle of swapping my E30 steering rack with an E36 rack that we I found at our local Pull-A-Part. Once I'm finished with the swap though, I'll swing on down as often as possible to help you out brother! It's really awesome that you're documenting all of the work you've been putting into this old girl. Seeing this thread for the first time has really got me wanting to finish my project this very second and give you a helping hand!

July 23 2014

So just want to make a small announcement concerning Ireland Engineering. I know these guys are very popular among r3vers, but I gotta say...they're pretty freaking awesome. I was installing their polyurethane rear trailing arm bushings, and accidentally ripped one of the bushings due to C-clamp malfunction. I didn't think it would work, but I gave them a call anyways. Long story short, super cool and friendly and people. After a quick confirmation, they sent me a replacement piece right away.

I didn't think it would work, but I gave them a call anyways. Long story short, super cool and friendly and people. After a quick confirmation, they sent me a replacement piece right away.

The replacement

Last edited by ksjdan; 10-29-2014, 04:30 PM.

Last edited by ksjdan; 10-29-2014, 04:30 PM.Comment

-

October 29 2014

Just a small update, but a big decision have been made to finish the swap by this year.

Its been a busy several months, with almost no time to really work on the 1990. Had to deal with some side projects, but now that the natures A/C is coming and new years is getting closer, this is a good time to pick the project back up.

Ive been staring at this half finished bushing install for the last 3 months, and it was getting too depressing. I had to do something about. So I pressed them all in with a $10 "kit" from Lowes and banged it in the subframe. Its a tight fitting with Ireland Engineerings control arm bushings.

So next up is the differential seals, some new fluid, and rear brakes. And once that has been completed, I think the engine will be ready to be dropped in. :) This is another thing that has been holding me back for awhile. The little plates used to block off the deleted SAP (secondary air pump) holes on the engine. Bimmerworld sells these little suckers for $50 shipped.

But last night, I found out that BMW actually makes a equivalent piece for $10 a pop (So 2x = $20). This may still sound ridiculous to those who have access to a CNC machine, but its something I can tolerate.

For those who are interested:

P/N: 11121438086 (block)

P/N: 11727514860 (gasket)

Comment

-

I hate when I write a post for 30 minutes on quick reply, and the goddamn forum logs you off and erases everything that was written! Too stressed to write it again.Comment

-

So everything Ive written again has ALL BEEN DELETED YET AGAIN. This time my overheating thinkpad died on me. I swear Lenovo had no idea what they were doing 10 years ago when they've just bought IBMs laptop.

May 8 2015

So it has been a while since I have done any work to the 325is. But I am resurrecting this build thread because some progress has been made. I have been caught up on other e30 issues until recently, so this build was put aside for several months. All I am going to say is that there are some dishonest e30 owners out there, and that everyone should be careful when dealing with untrusted/un-vouched sellers.

Anyways with all that shit put in the past, back to the 325is build. I think it is now fair to say that this car has come quite a long way since the purchase almost 3 years ago. I am very glad I was dealing with a honest seller and a car that was completely stock and unmodified. All the nuts and bolts were in their designated locations (little rusted, but hey they were there), making the work much easier then having to play the guessing game or looking up diagrams on the parts catalog.

So before going into hibernation, I have actually finished redoing the subframe. I had the subframe and the control arms sandblasted, repainted and coated with a layer of undercoating. The slight texture actually looks rather nice in my opinion. New wheel bearings, e-brake lines, brake shoes, differential seals, Redline fluid and polyurethane bushings.

Since the last update, I have actually removed some components that were installed earlier in the build. The original KYB cartridges and Eibach springs didn't quite seem like a proper upgrade for this car. The shocks and springs were replaced with a more durable and stiff, Bilstein HD and H&R Race. With the new suspension bits, the rear end was put back into place.....finally!

Rear suspension. The rear sway bar was also replaced with a E30 M3 one.

Front suspension

May 20 2015

So I took things pretty slowly with the car this next few weeks to help with the yard work. New mulch, garden pruning, seeding, bit of repair work and a crap ton of weed pulling.

Today, I started working on the motor. I initially wanted to get the rear of the motor started few weeks ago, but the pilot bearing was missing, and the rear crankshaft seal was slightly leaky.

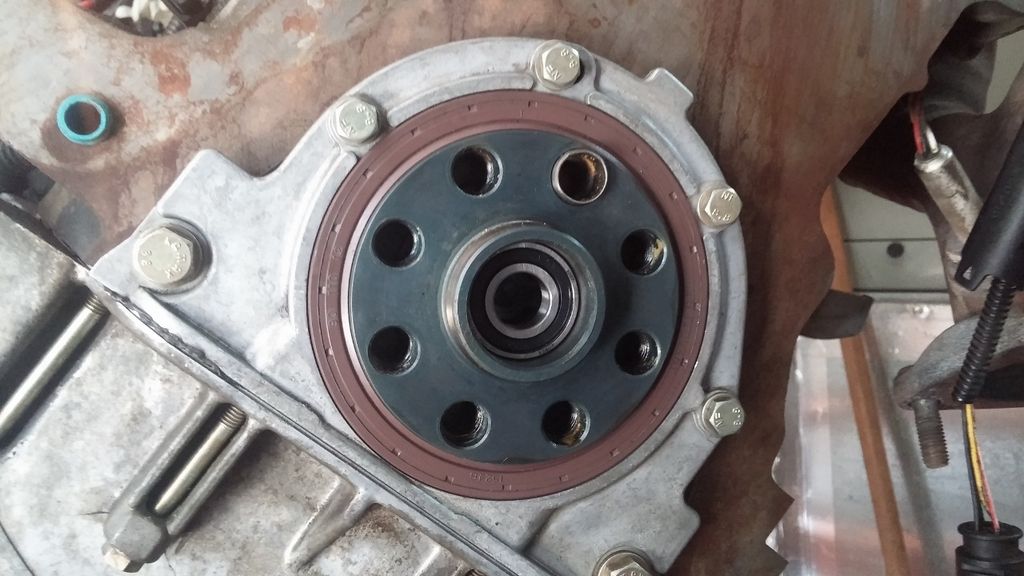

New FAG bearing was pushed in along with a DPH (Dichtungspartner Hamburg) which I have never heard of in my life. German made and seems like quality product.

DPH represented by this mighty, fierce seal.

May 21 2015

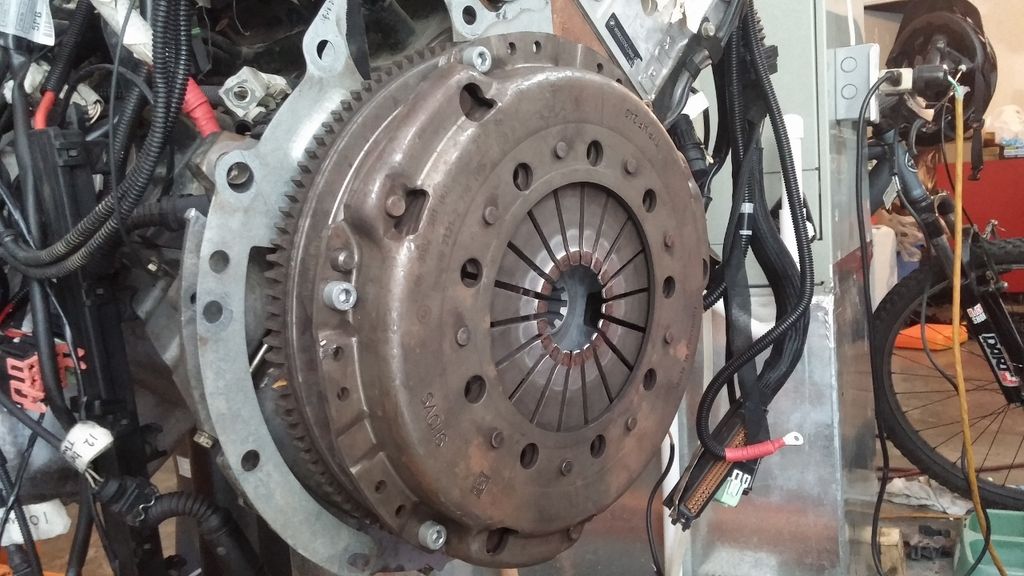

The fly wheel (with 70k miles) was still in good condition, so I decided to just put it in. I know a lot of people are against the dual mass flywheel, but I don't want this car to be extra clunky when shifting. The surface was lightly prepped with a bit of 120 grit along with the pressure plate. Little bit of brake cleaner, and they were all mated together with a new Sachs clutch disc. And yes I used a clutch alignment tool!

The included TOB seemed to be in good working condition, but I replaced it with a new one just in case. New INA piece with a dab of antiseize on the sliding portion of the tranny rod and contact points.

Aaaaand they were put together! Took bit of force get it close all the way, but it finally caved after bit of wrestling.

Next up was bolting on the flex disc. I think some people install the flex disc on the driveshaft portion first. But after installing one of these for the m20 drivetrain, i noticed it was a pain tightening the tranny side once everything was put on the car. Actually dislocated my shoulder trying to torque it down last time.

Some locktite on the bolts and forgot tot take a picture of the final product. Oops. lol It was torqued down to 56 ft/lbs, and off to the next thing.

May 22 2015

The front end of the drivetrain was looking pretty complete, so i started moving down and started working on the driveshaft. After double checking the driveshaft to make sure there were only 4 bolts on the differential side, I pealed off the center support bearing one layer at a time. Yet another part that is a total pain to remove. the outer "ring' was removed by puncturing holes with a flathead. next, the rubber surrounding was removed with a few mallet punches. And finally the effing bearing was pulled using a 3 jaw puller.

New CSB was put in and Im done with it for now. I didn't connect the splines yet because the length is different from the original e36 tightening point. So that'll be done when it is being installed.

The selector rod was then modified to accommodate the Z3 shifter. I wasn't sure if it was necessary with the harmonic-balance lacking on the e36 driveshaft, but it wasn't difficult shaving it down a few millimeters and I dodn't want to disassemble the entire unit after it was put together.

No sparking picture this time, nor the bbq grill paint. haha. Found some decently strong looking silver paint in the garage, so I sprayed on a layer.

I would have loved to go with a autosolutions ssk or other quality ssk options, but this seemed like a good enough "upgrade" for the time being.

Shaved and painted

This shift arm receiving end bolted on. Again, I would have preferred the polyurethane piece, but I couldn't remember who made those, so this will suffice.

After all the prep work has been taken care of, it was finally time for the exciting part. I remember it was bit of a pain in the butt getting the m20 out of the car. So it was nice having a buddy help out with the install.

The motor goes in as easy as:

1

2

3 4 5 6 7 (notice AC compressor had to come off)

8 9 10 11 12 13 14 15 16 17 18 19 ....... 61 62 63 64 65 66 67 68 69

Aaaaaaaaaand 70

Holy crap that was a good exercise.

Cool shot with the E30s garage mate.

If you've been following this thread, can you guess how many different garage mates the 30 has been through? :D

May 23-24 2015

Time to fill up the hole between the engine and the radiator support brace!

I originally tried fitting a e36 fan clutch + blade assembly, but it was a no way jose. After looking up a few pictures on google, I saw a red e30 (m3 i believe) swap car with 325 radiator and a m20 fan blade. So I gave it a try.

With just e36 fan clutch. Looked like it might clear with few millimeter of leeway.

With m20 piece. So much room for activities!!

May 25 2015

Next up, just a simple bolting on of the new, pricey, shiny, Behr/Hella A/C condenser.....not really. It seems like satan had a bit of fun with this total crap unit. Without much worries, I pulled the condenser out of its box/wrapping, and tried fitting it right into its slot. It didn't fit. Surely I must be doing something wrong. I mean its a $250 Behr/Hella condenser. Tried again and still doesn't fit. What the hell? Tried test fitting the old unit, and it slides right in.

Flip over the condenser to read the label:

The black pigment on the white sticker is splattered in a shape of Anglo-Saxon characters, BMW 3 E30. Which i think means the E30 BMW....

I go on google and it tells me compatible for all e30s including the m3.

So I tried installing it up side down, backwards, and all possible fitments and still doesnt fit. I ended up having to remove both upper and lower mounting piece. The upper mounting piece has two welded tabs for bolting onto the radiator support. They had to be drilled out.

After drilling it out, The tabs were flipped over and screwed into place. The lower mounting piece had to be turned over and the aux fan mounting tab had to drilled out and removed completely. I would have saved the tab if I was reusing the aux fan, but Im going with a electric.

After a bit of disappointment, the condenser slid into place....barely.

Time to give Behr a call and ask what the hell just happened....

That's all the update I've got for now!Comment

-

August 09 2015

Picked up a rear passenger and front driver caliper from pull-a-part. The ones on the car were working fine, but the bleeder screw was rusted on and broke off. after trying to remove it, I gave up. The front caliper is working great. But the rear one i picked up is not getting bled. there is pressure up to the brake line, but nothing is coming out of the bleeder valve. Time to fish out another one. :/

Also my mishimoto radiator is coming in few days! Let's hope it doesnt leak!

With the radiator attached and once i figure out how to install the 528i fuel rail, Ill be about 98% done with this project!!!Comment

-

-

Looks like good progress despite getting the shaft from a few companies.

Just a random FYI now that I used these...

They will work, but they need the sides filed down a lot, and the hole opened and dragged significantly to fit. Now that I know this, I would either just weld up the holes, or buy the BW SAP delete plates.Originally posted by priapismMy girl don't know shit, but she bakes a mean cupcake.Originally posted by shamesonUsually it's best not to know how much money you have into your e30Comment

-

Were you having problems with a gasket? I will find out more when I get the car back from the muffler shop tomorrow, but I dont think it was leaking on mine.Looks like good progress despite getting the shaft from a few companies.

Just a random FYI now that I used these...

They will work, but they need the sides filed down a lot, and the hole opened and dragged significantly to fit. Now that I know this, I would either just weld up the holes, or buy the BW SAP delete plates.Comment

-

September 25 2015September 18-20 2013

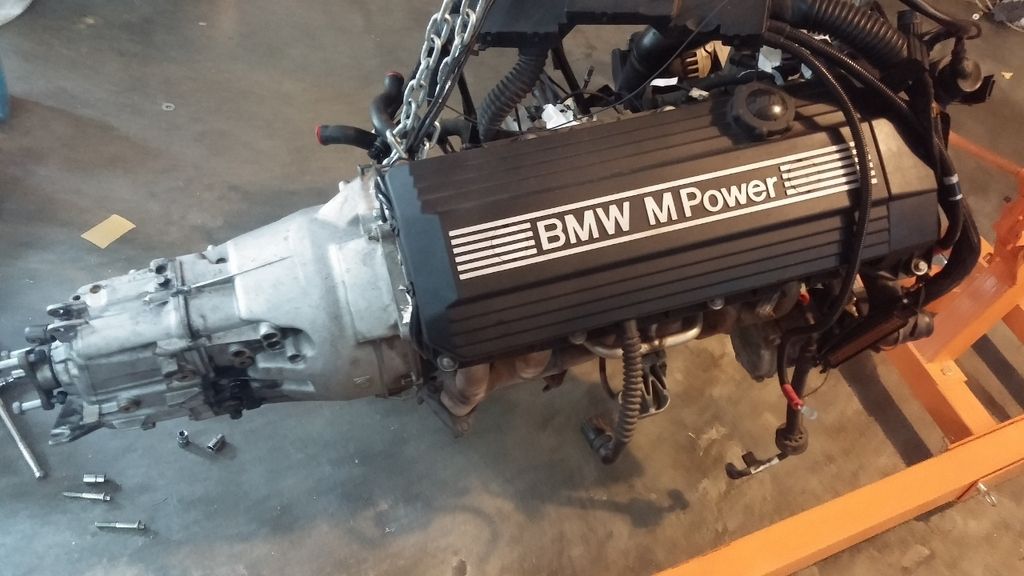

The project I am currently working on is no doubt the biggest one I have tackled so far. For this work, I actually called my friend over to help remove the old m20 and the trans. I did most of prep work such as exhaust, driveshaft draining fluids, disconnecting the harness etc the day before and some on the day of. The work was relatively easy as its only been several months since the exhaust and driveshaft bits were re-installed. I was really excited about the engine removal as it was the first time I performed this. After asking a few questions and reading a few articles, the work didn't seem all that difficult. I picked up a cherry picker locally, and my friend and I started removing the old motor from the bay later that night.

The removal was pretty straight forward and not that big of a problem. The powersteering pump and the AC compressors were in the way so they were removed (picture taken before). But other than that, the engine came out swiftly without much of a fight.

Here are some photos!

Last photo before it was removed. Despite having 150k+ miles on it, it ran strong and pretty smoothly right until the removal. The M20 and a 5 spd mt transmission is going to be listed on the classified, so look for it soon! :up:

Shot with the ///M.

Cant believe its already been 2 years since the project officially started. How time flies.

Engine is running now! Id say its pulling very strong. Gave the usual pedal push, and rear tires were spinning.

Shot a quick vid while taking it to a exhaust shop to get the e36 328 cats and muffler. Its not the most popular route, but it should suffice for now. If I decide to make it into a dedicated track car, a catless (maybe just resonator) + better flow/lighter muffler will be sourced.

By the way, its hard to tell in the video, but the car was REALLY loud. I was wearing ear plugs to the shop so I dont start bleeding out of them.

...and wheel is attached a bit crooked.

Comment

-

Awesome Thread! Inspires me to paint Sterling! Resto/Mod threads are the best IMO. Keep up the good workComment

Comment