I think its fair to say this e30 project is coming to a conclusion. The swap was a success and the car can really haul ass.

Only thing I really need now is to replace the 3.73 diff with a 2.93.

LMK if you have a 2.93 LSD for sale!

Final cliff:

1989 build 325is - sterling silver / silver leather

Swap components:

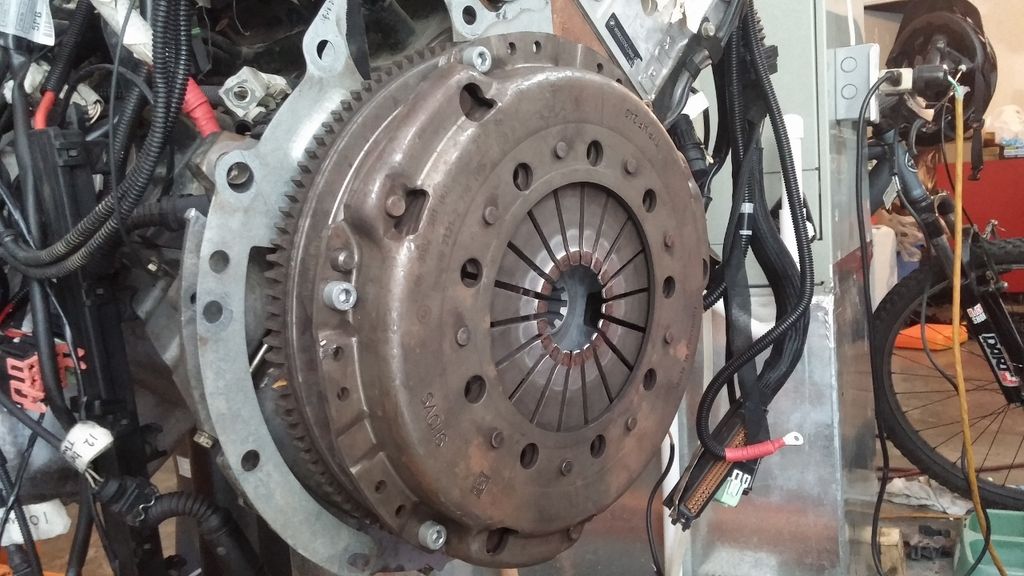

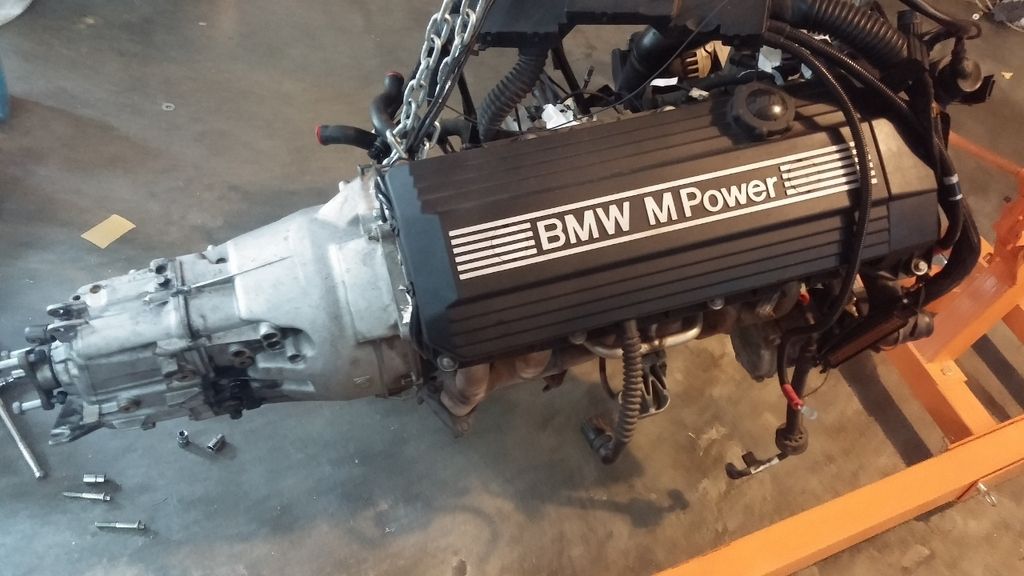

- S52B52 swap with about 52k miles

- - Sap delete

- Kept s52 intake for more lower end torque

- Early model e39 fuel rails with built in valve

- Andrew's harness

- Merkert's temp sensor

- e28 engine mounts

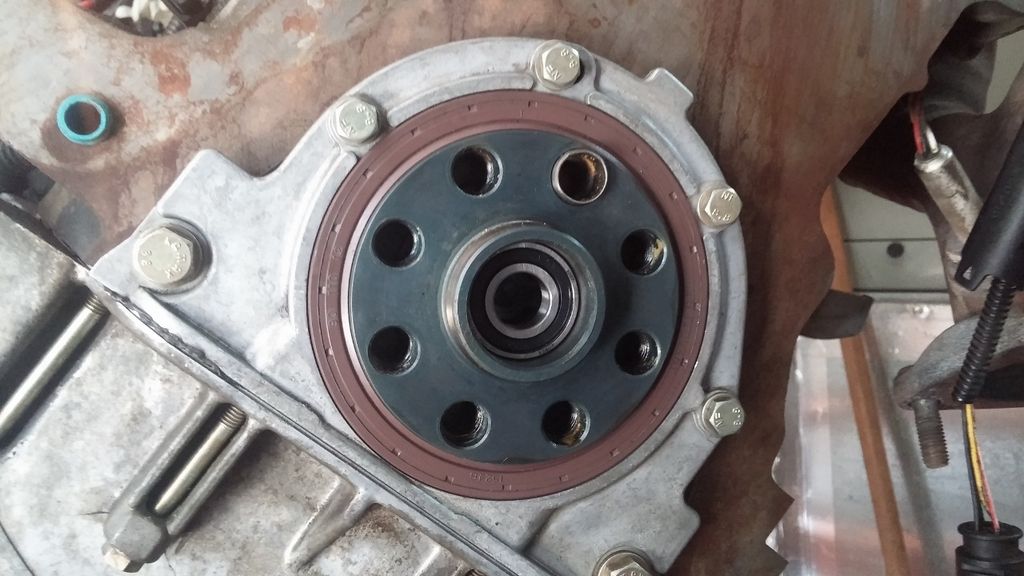

- ZF 226 5-spd transmission with about 70k miles

- - z3 OE SSK with ZHP knob

- P-car 944 brake booster (kinda shitty lol)

- Mishimoto aluminum radiator (8/10 fitment)

- e36 328i 4-bolt driveshaft

- Electric fan conversion

Exhaust

- stock headers

- custom 2.5 piping section 2 with 200 cell cat

- Dynomax ST muffler 17733

- Dual chrome exhaust tip

Other replacements

- H&R Race Springs + Bilstein HD

- E30m offset lollipop

- Rear subframe redone

- - sandblasted

- Ireland Engineering soft polyurethane bushings (all except for diff)

- FAG bearings

- 3.73 LSD resealed and Redline fluid (707 represent!)

- Euroweaves with fulken shet tires

- hoarded collection of 15" hub caps

I didn't think it would work, but I gave them a call anyways. Long story short, super cool and friendly and people. After a quick confirmation, they sent me a replacement piece right away.

I didn't think it would work, but I gave them a call anyways. Long story short, super cool and friendly and people. After a quick confirmation, they sent me a replacement piece right away.

Leave a comment: