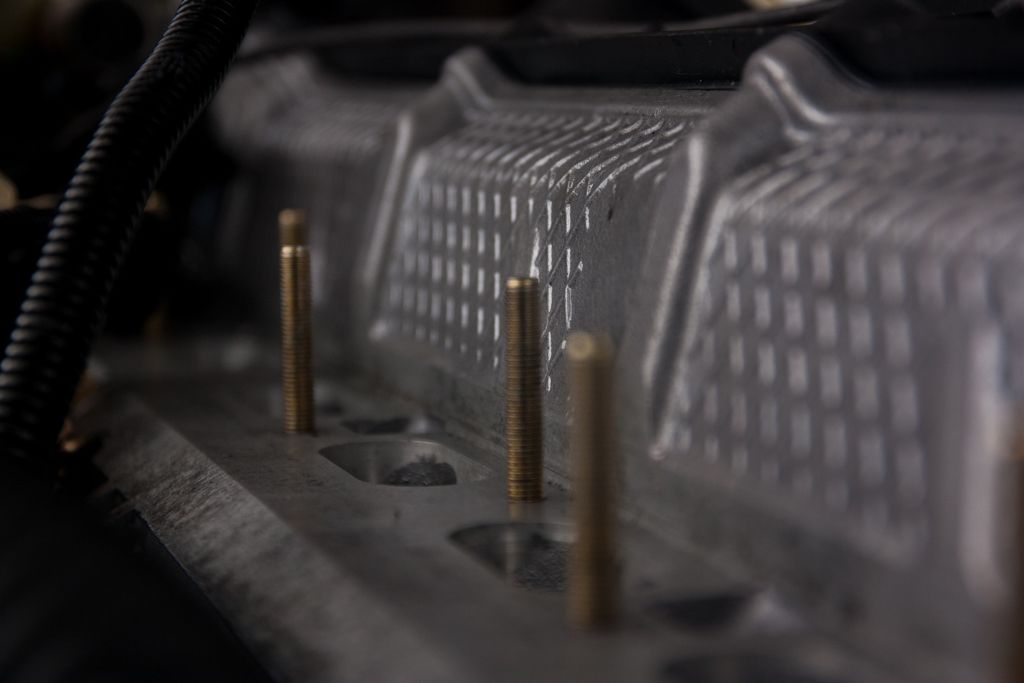

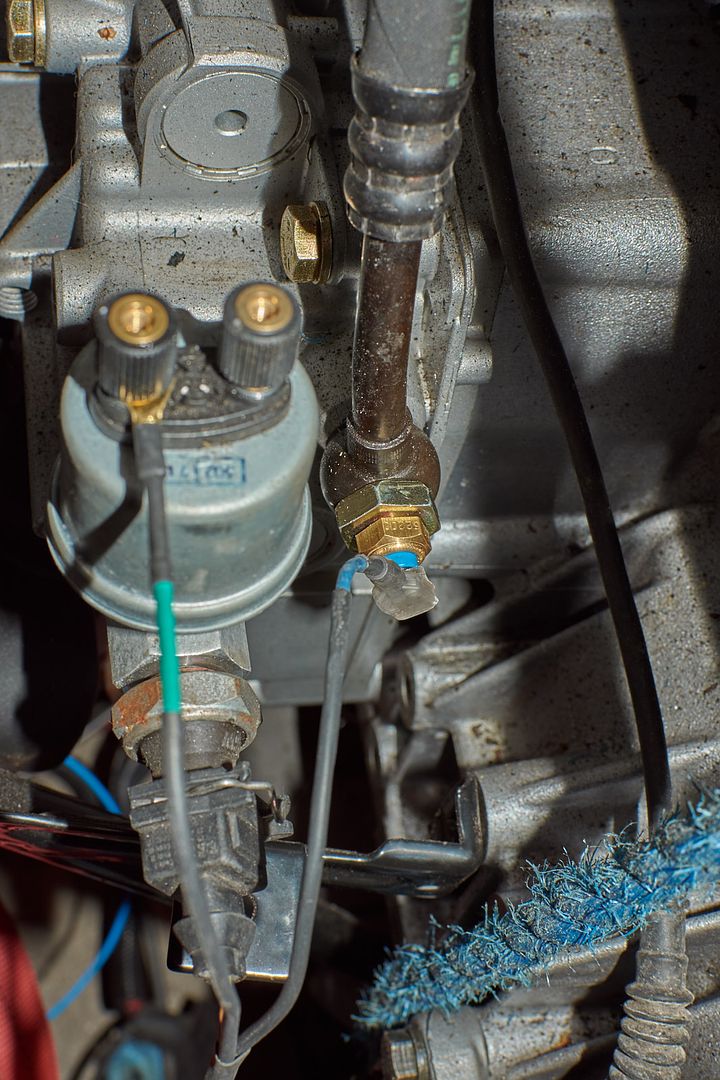

Slowly but surely things are coming together. I spent the last 4 days or so doing the brake and fuel lines.

I didn't enjoy these 2 jobs at all and hope not to have to do them for a long time! I used kunifer hardlines all round with stainless braided lines and also stainless brake nuts.

I had bought a new T-Piece which turned out to be imperial so I atacked the old one with the angle grinder and used it, should be fine anyway.

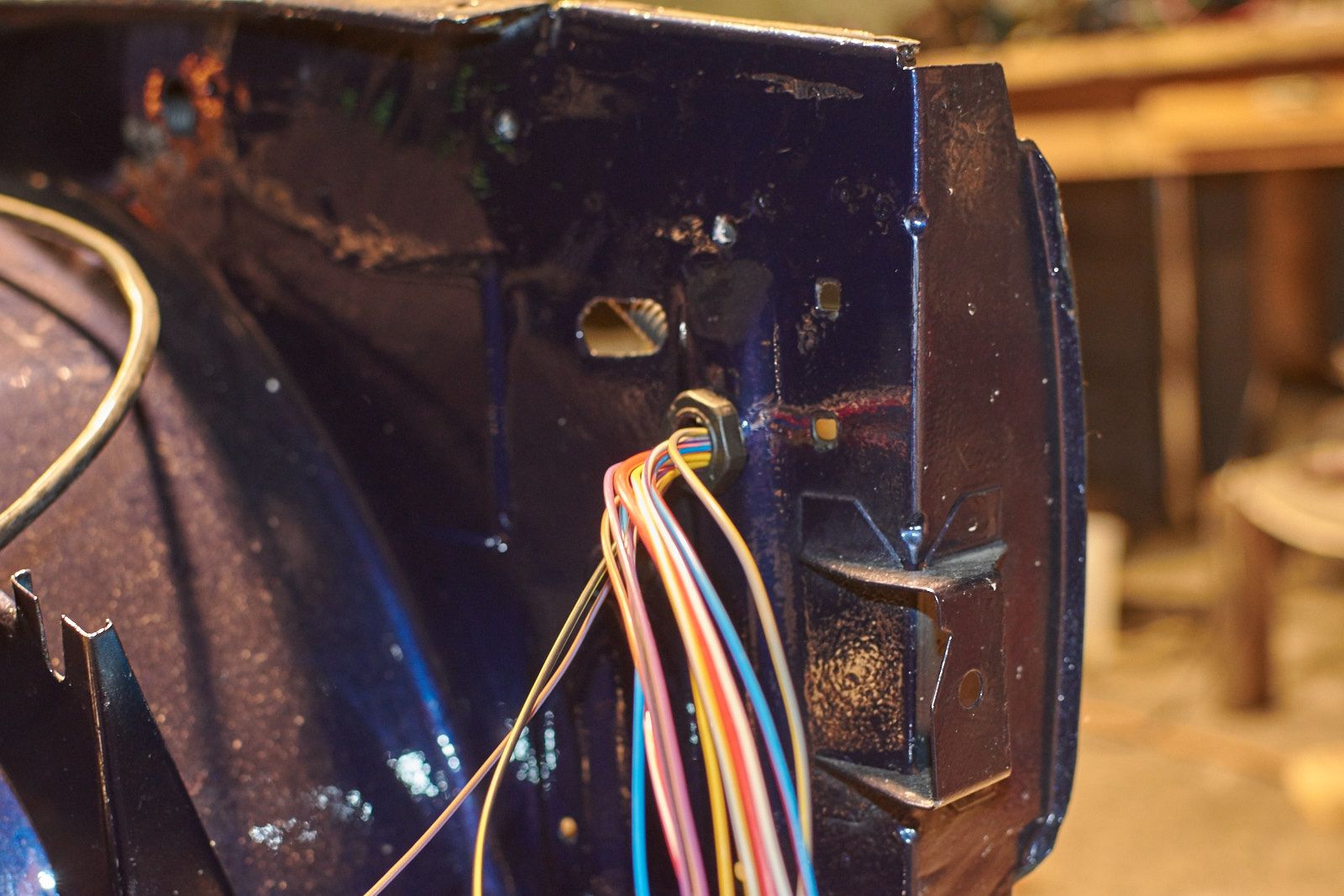

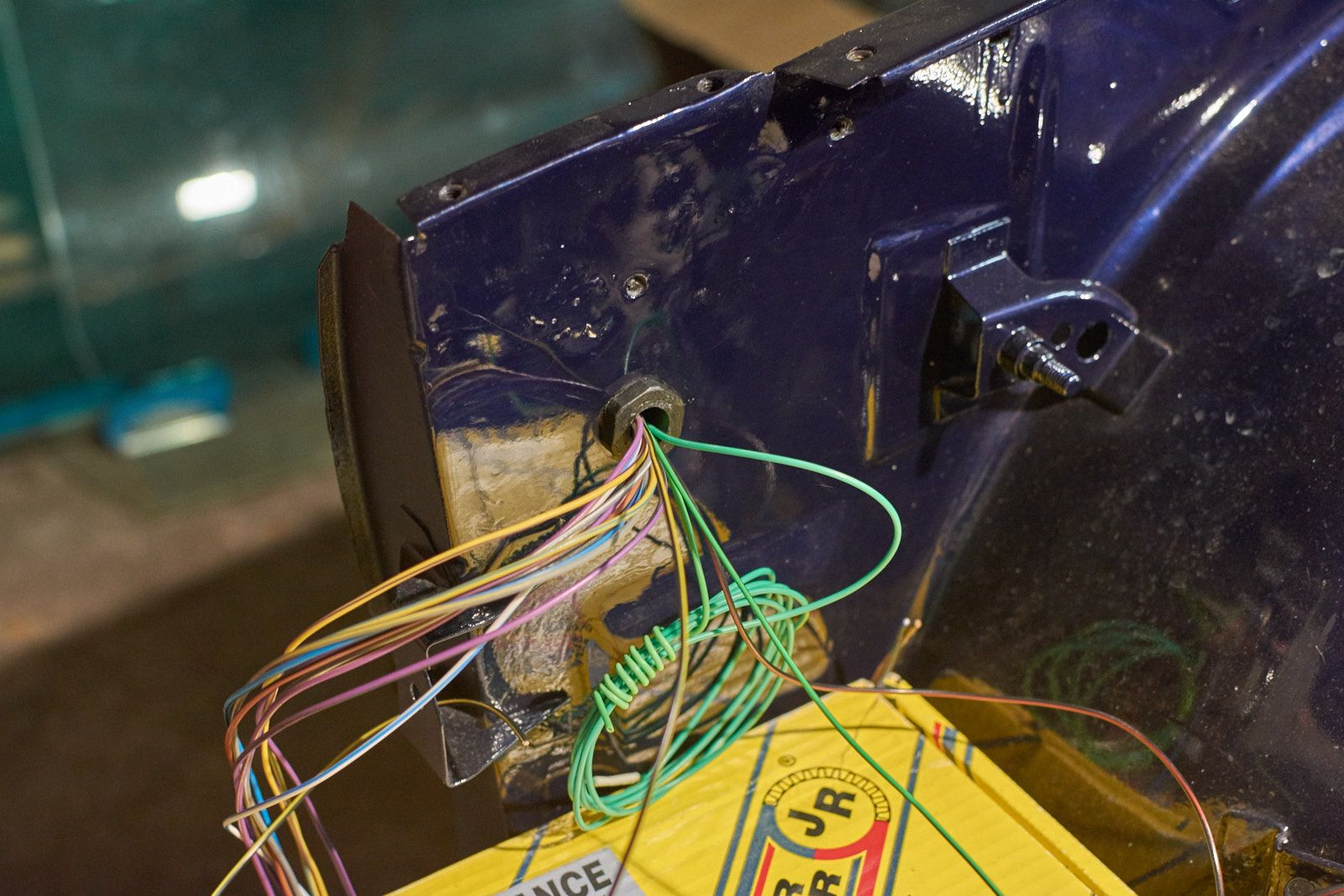

Lines at the rear of the car

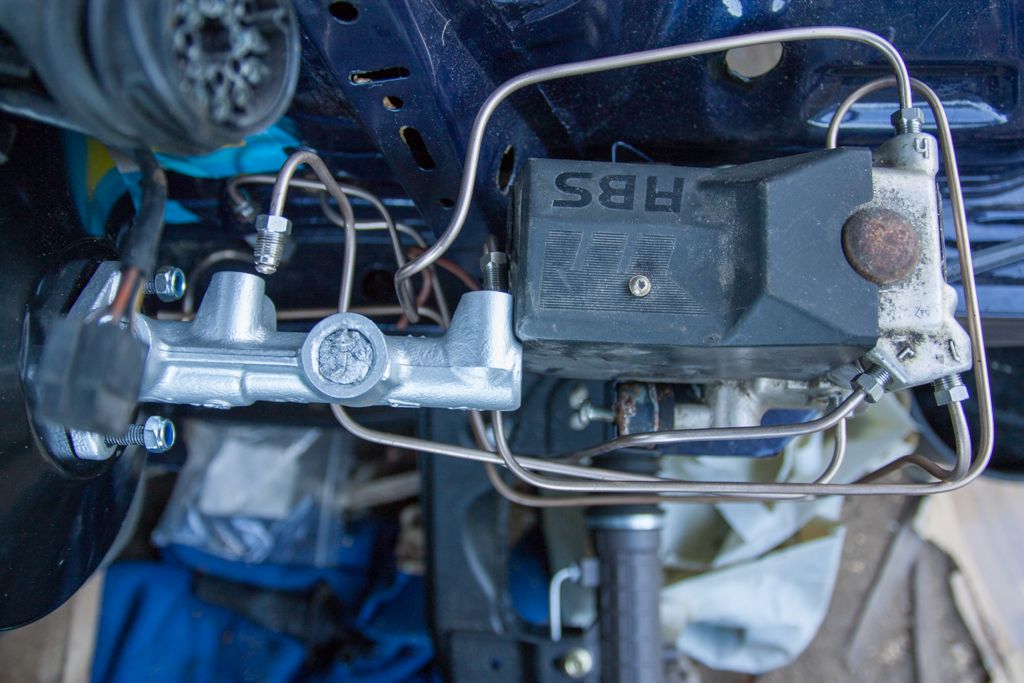

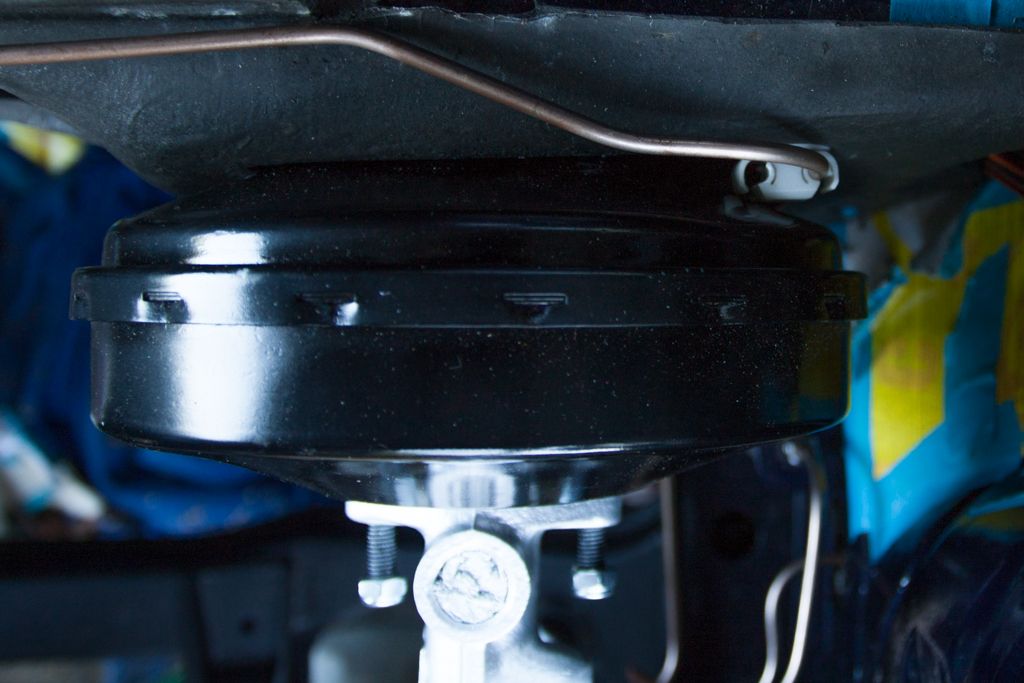

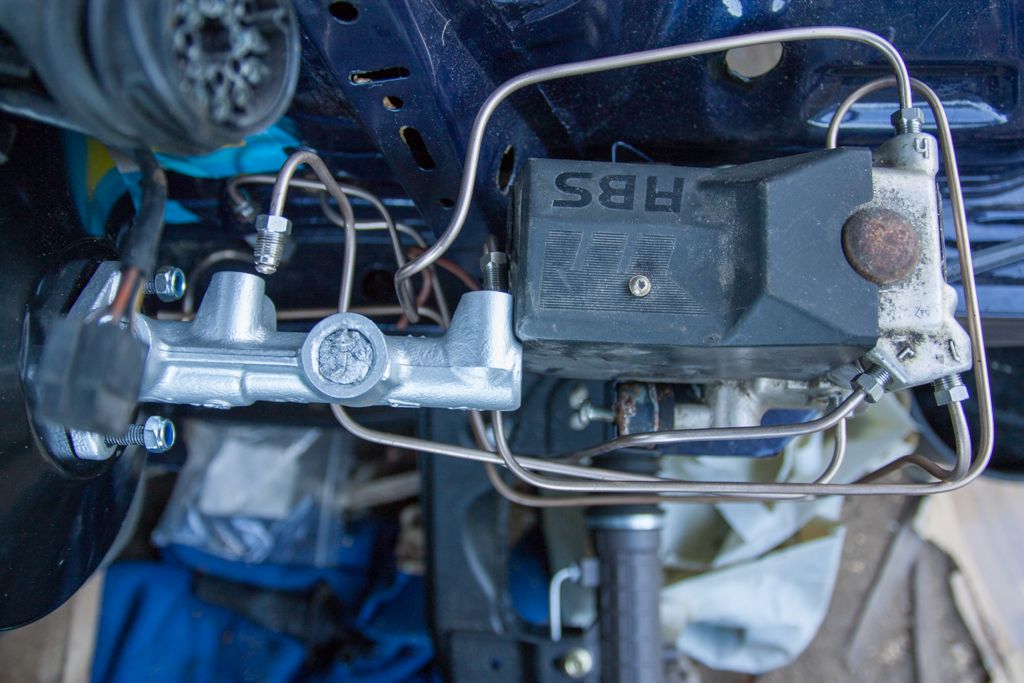

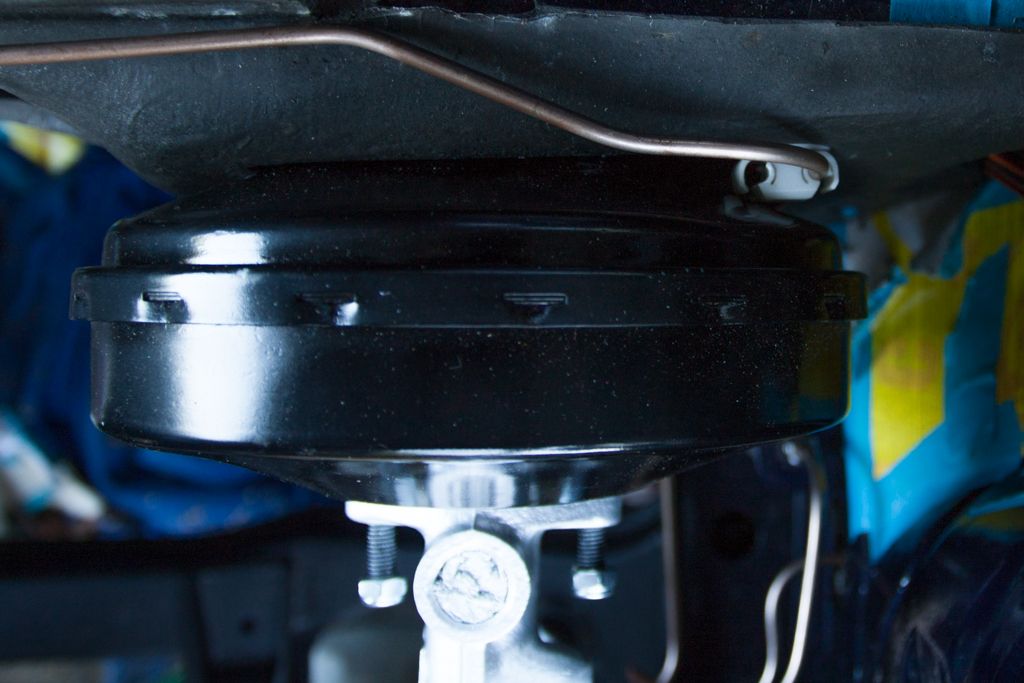

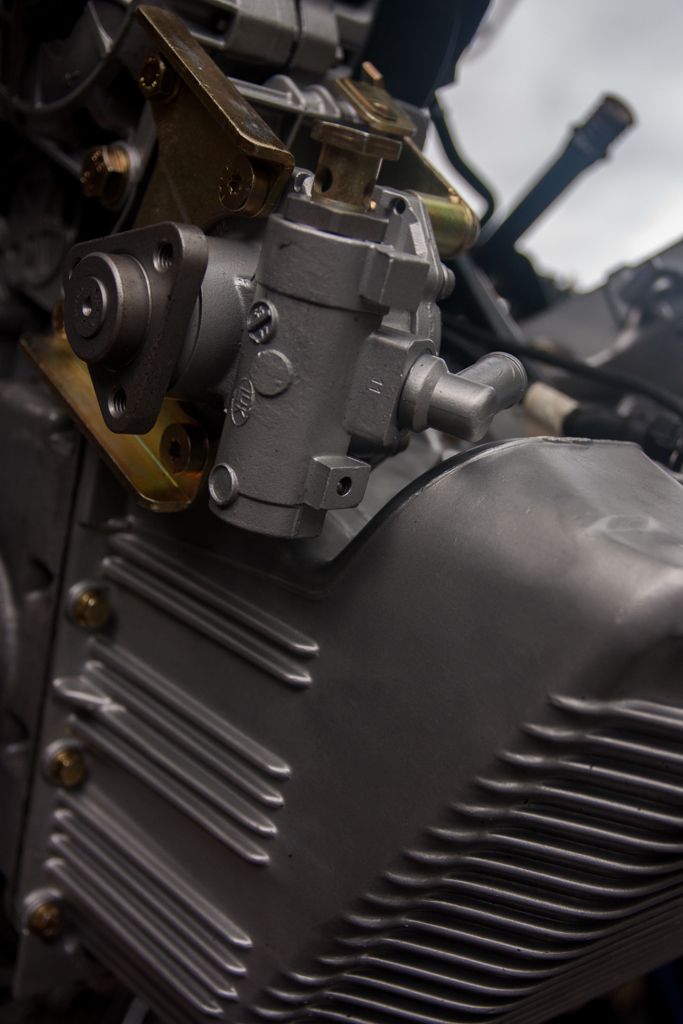

Few small problems :( When I mocked up my ABS relocation I must have used the E30 servo, which I think isn't as deep as the Clio one

With everything tightened up properly there's maybe 2mm between the two, might just have to shave a corner of the abs cover!

I also have a problem with the servo and a brake line clip getting in the way of each other

Dent the servo or shave a little of the clip? If I space the servo out I might not be able to bolt it up and it will foul the ABS unit.

Another problem noticed when doing the brake lines is that my diff isn't centred, is this normal, should I be worried? I couldnt seem to move it to the centre when I tried.

I also got the fuel lines installed but no pics apparently, just need to trim them in the back and by the tank next tiem I'm home.

Anyone know can the tank go on with the subframe in place or does it need to come off?

I'm also missing the 2x pipes that are supposed to run over the top of the tank if anyone has them?

I didn't enjoy these 2 jobs at all and hope not to have to do them for a long time! I used kunifer hardlines all round with stainless braided lines and also stainless brake nuts.

I had bought a new T-Piece which turned out to be imperial so I atacked the old one with the angle grinder and used it, should be fine anyway.

Lines at the rear of the car

Few small problems :( When I mocked up my ABS relocation I must have used the E30 servo, which I think isn't as deep as the Clio one

With everything tightened up properly there's maybe 2mm between the two, might just have to shave a corner of the abs cover!

I also have a problem with the servo and a brake line clip getting in the way of each other

Dent the servo or shave a little of the clip? If I space the servo out I might not be able to bolt it up and it will foul the ABS unit.

Another problem noticed when doing the brake lines is that my diff isn't centred, is this normal, should I be worried? I couldnt seem to move it to the centre when I tried.

I also got the fuel lines installed but no pics apparently, just need to trim them in the back and by the tank next tiem I'm home.

Anyone know can the tank go on with the subframe in place or does it need to come off?

I'm also missing the 2x pipes that are supposed to run over the top of the tank if anyone has them?

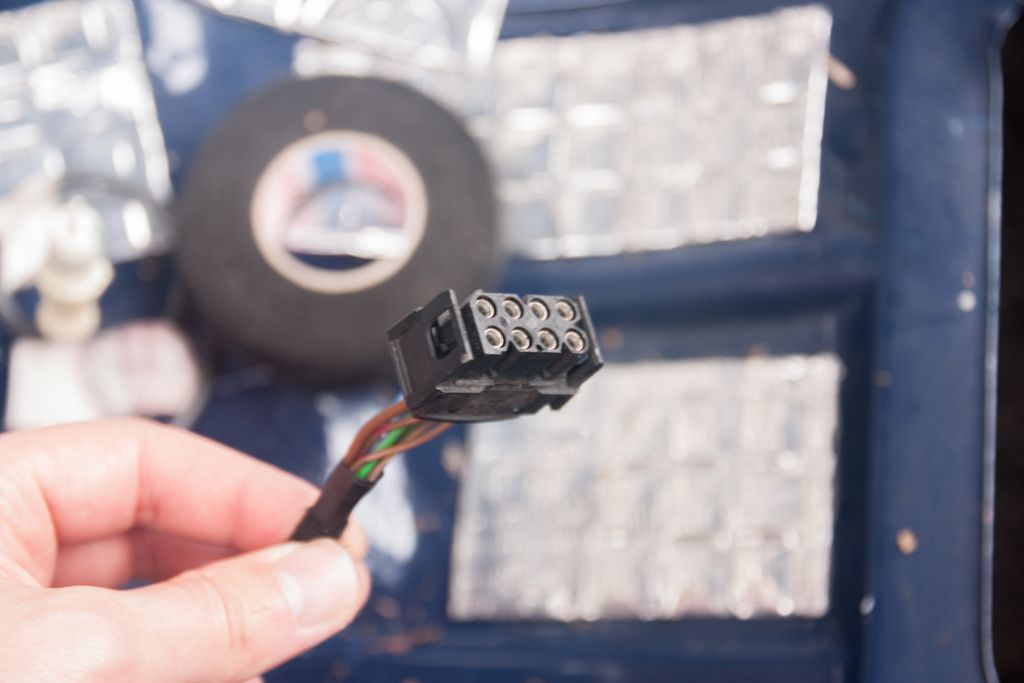

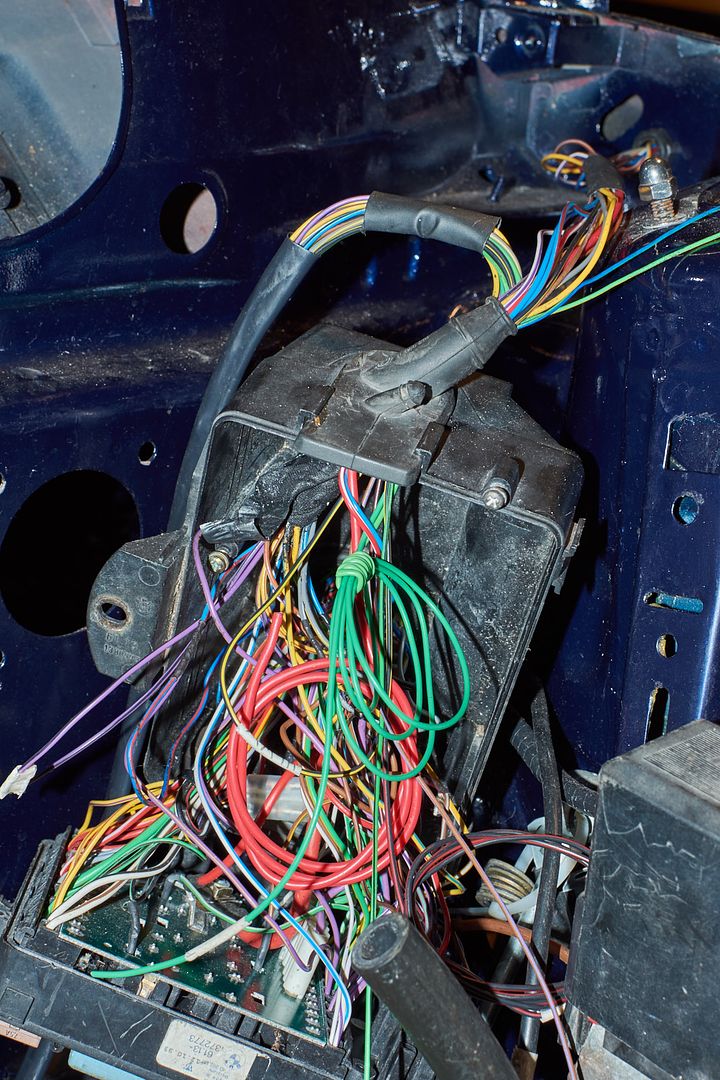

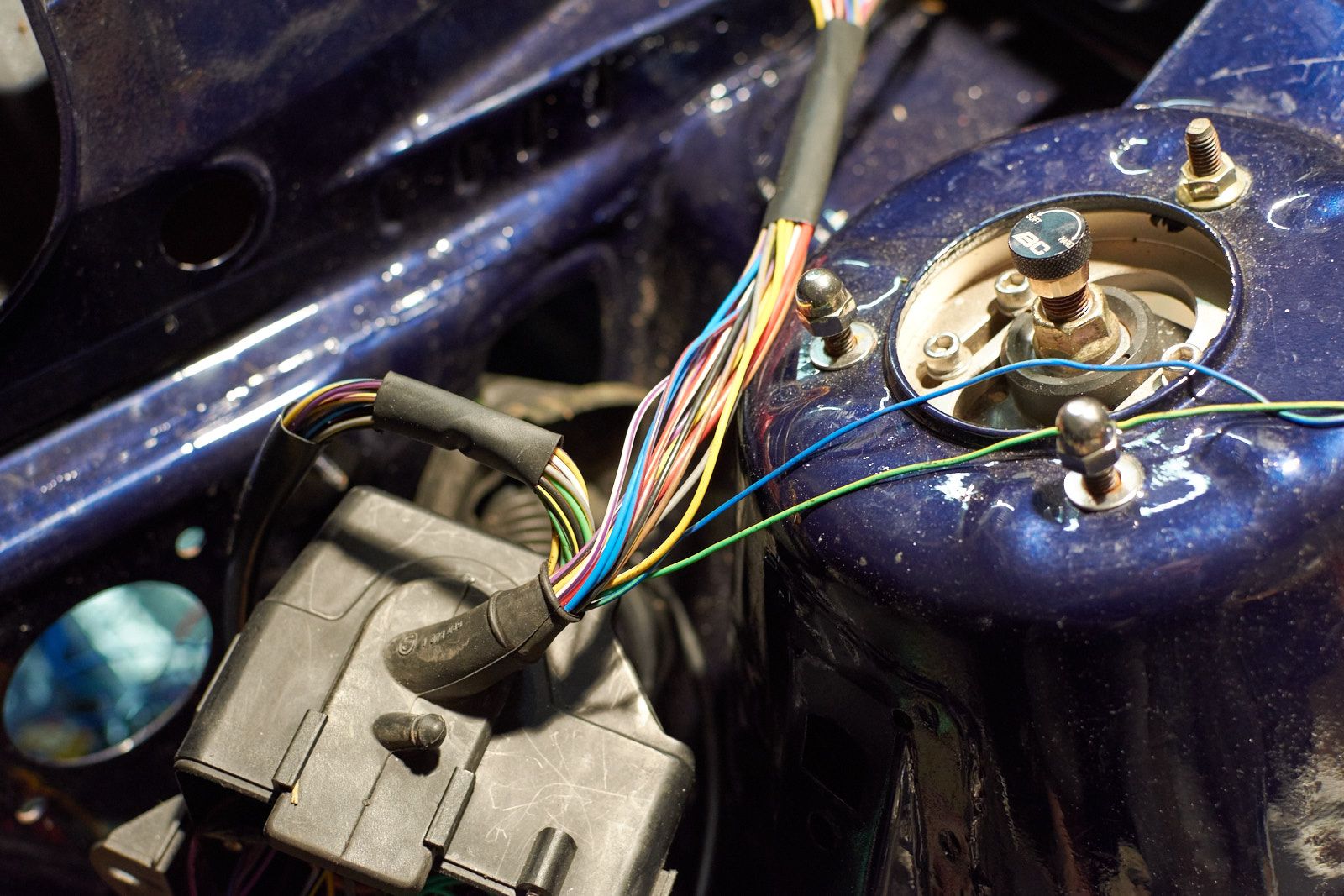

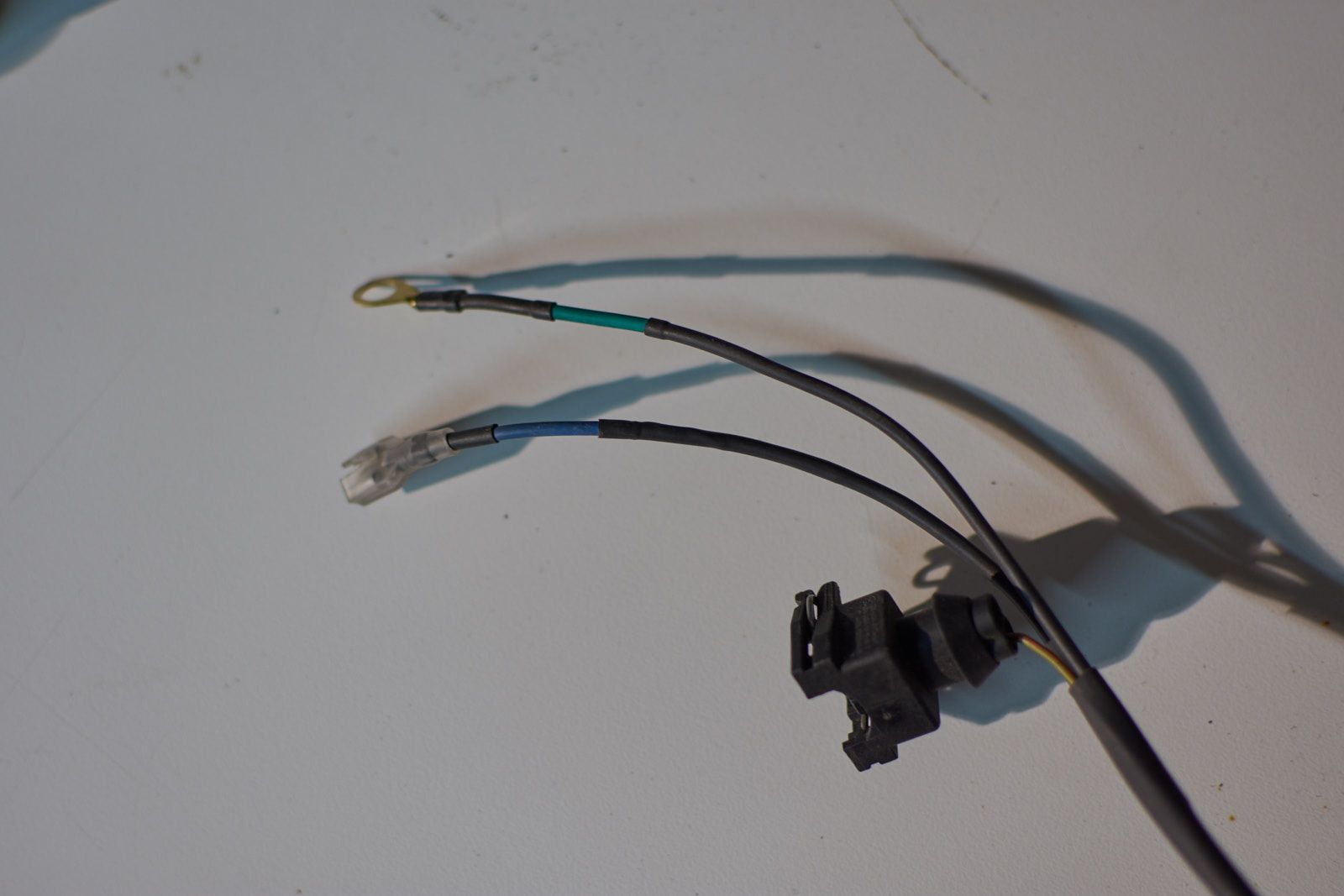

I spent a good while untangling various parts of it while laying it out inside the front of the car.

I spent a good while untangling various parts of it while laying it out inside the front of the car.

That took a bit to arrive but it made everything about 100x easier. In the event I missed a wire I left one long redundant wire in the loom which runs to/from the fuse box so I could tape wire to this and pull it through if I have to (which I have with a few cables since).

That took a bit to arrive but it made everything about 100x easier. In the event I missed a wire I left one long redundant wire in the loom which runs to/from the fuse box so I could tape wire to this and pull it through if I have to (which I have with a few cables since).

Comment